Staged powder spraying entrained bed gasification furnace and gasification method thereof

A gasifier and entrained bed technology, applied in the field of clean utilization of carbon-containing fuels, can solve the problems of difficult gas-solid flow field, oxygen depletion of nozzles, short operation period, etc., to reduce high temperature sintering and fuel bonding, simplifying The effect of gasification nozzle structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

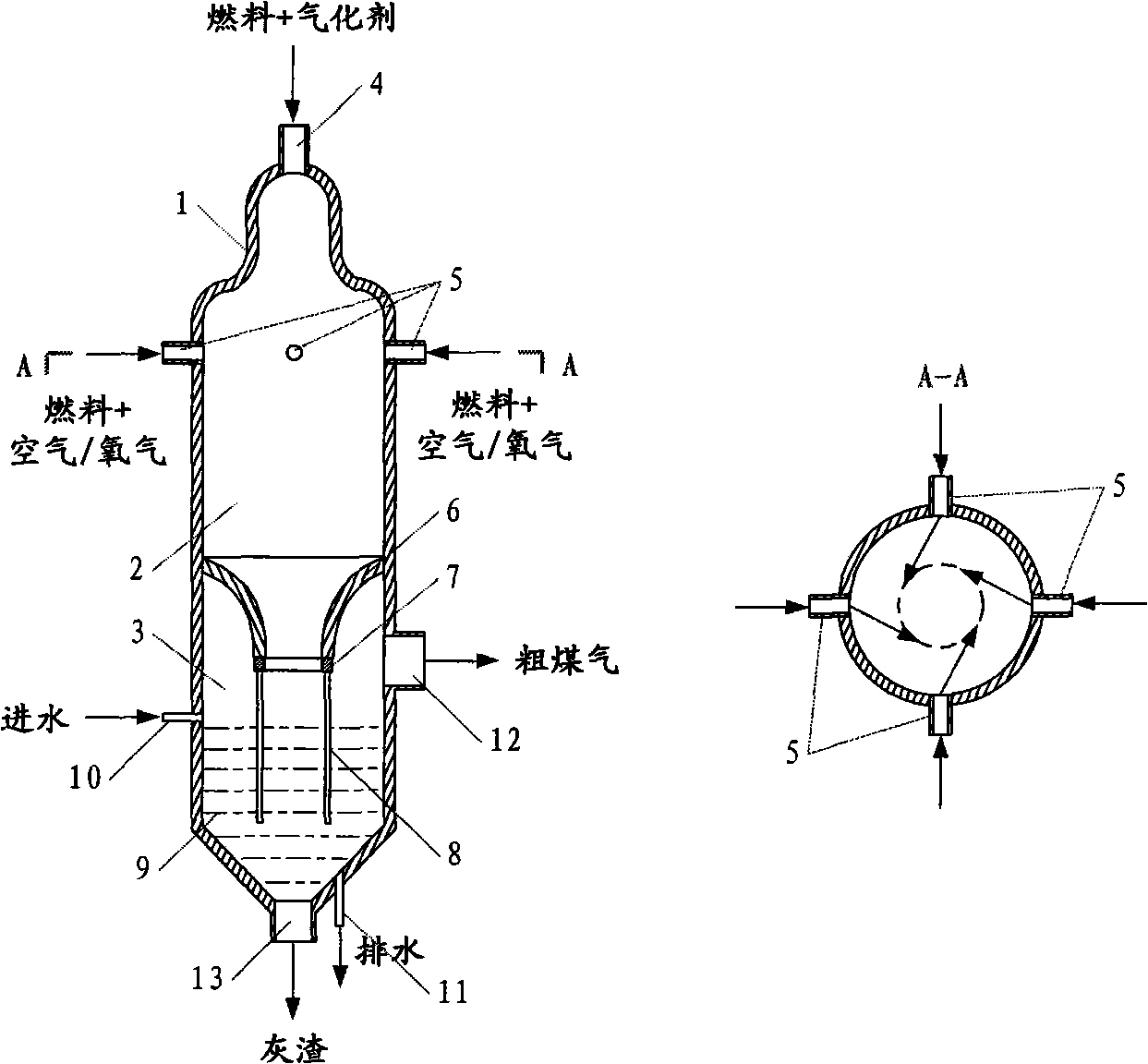

[0045] The entrained bed gasifier 1 of the semicircular dome, non-equal cross-section, and four combustion nozzles arranged along the gasifier is as follows: figure 1 As shown, it includes: gasification chamber 2 and chill chamber 3.

[0046] The gasification chamber 2 is circular in section, the upper section of the gasification chamber 2 is small, the lower section is large, and has a semicircular dome. The gasification chamber 2 includes a gasification nozzle 4, four combustion nozzles 5, a gasification Room Exit 6. The gasification nozzles 4 are located on the semicircular dome of the gasification chamber 2 , and the combustion nozzles 5 are symmetrically distributed along the cross section of the gasification chamber 2 on the upper part of the gasification chamber 2 . The axis of the gasification nozzle 4 in the gasification chamber 2 coincides with the axis of the gasification chamber 2, and the section formed by four combustion nozzles 5 distributed symmetrically along...

Embodiment 2

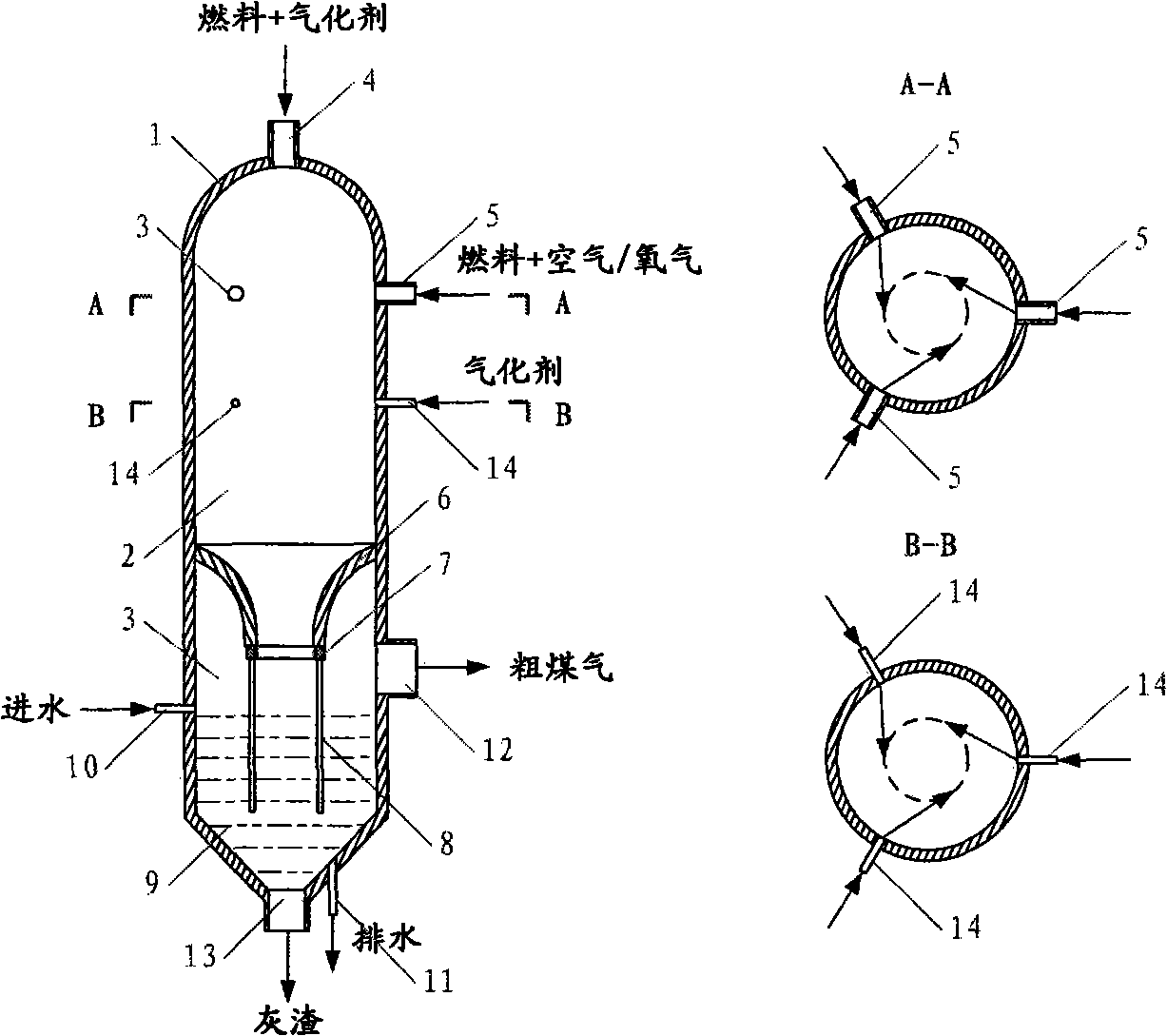

[0051] The entrained bed gasifier 1 of the semicircular dome, equal section, and three combustion nozzles arranged along the gasifier in this embodiment is as follows: figure 2 shown. Different from Embodiment 1, the gasification chamber 2 in this embodiment is a gasification chamber with equal cross-section, and there are three combustion nozzles 5 arranged in the gasification chamber 2, which are evenly arranged along the cross-section of the gasification chamber 2 . In addition, three gasifying agent replenishment ports 14 are arranged below the combustion nozzle 5 , arranged at the same angle as the combustion nozzle 5 , and the cross-sectional axis of which is perpendicular to the axis of the gasifier 2 .

[0052] The difference from Example 1 is that during the gasification process, the mixture of fuel and air / oxygen used for preheating combustion is sprayed at a certain angle (along an imaginary tangential circle in the gasifier) from three combustion nozzles 5 respe...

Embodiment 3

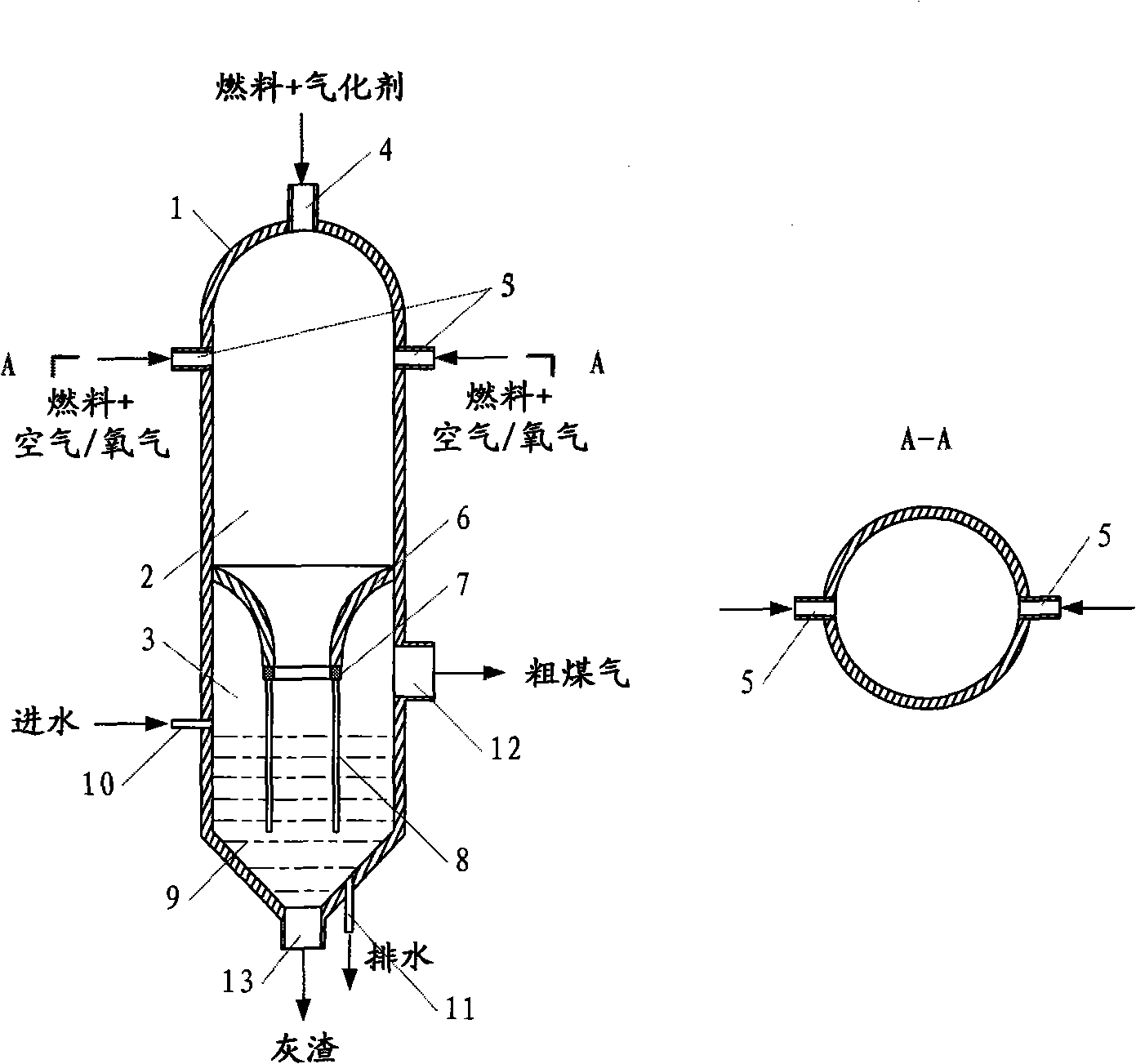

[0054] The entrained bed gasifier 1 of the semicircular dome, equal cross-section, and two combustion nozzles arranged opposite to each other in this embodiment is a step-by-step powder spraying entrained bed gasifier 1 such as image 3 shown. The difference from Example 1 is that the gasification chamber 2 used in this embodiment is a constant-section gasification chamber, and two combustion nozzles 5 are arranged on the upper part of the gasification chamber 2. The axis of furnace 2 is vertical.

[0055] During the gasification process, the fuel used for preheating combustion and the mixture of air / oxygen are sprayed and burned from the two combustion nozzles 5 respectively, forming strong disturbance and impact above the gasifier, increasing the gas-solid gap. mass and heat transfer between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com