Angle-adjustable four-pipe powder feeding nozzle for laser direct forming

A laser direct forming and adjustable technology, applied in laser welding equipment, welding equipment, coating and other directions, can solve the problems of nozzles that do not have the ability to adjust the powder incident angle, poor powder flow uniformity, and low powder utilization rate. Good convergence effect, long working life, not easy to block powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

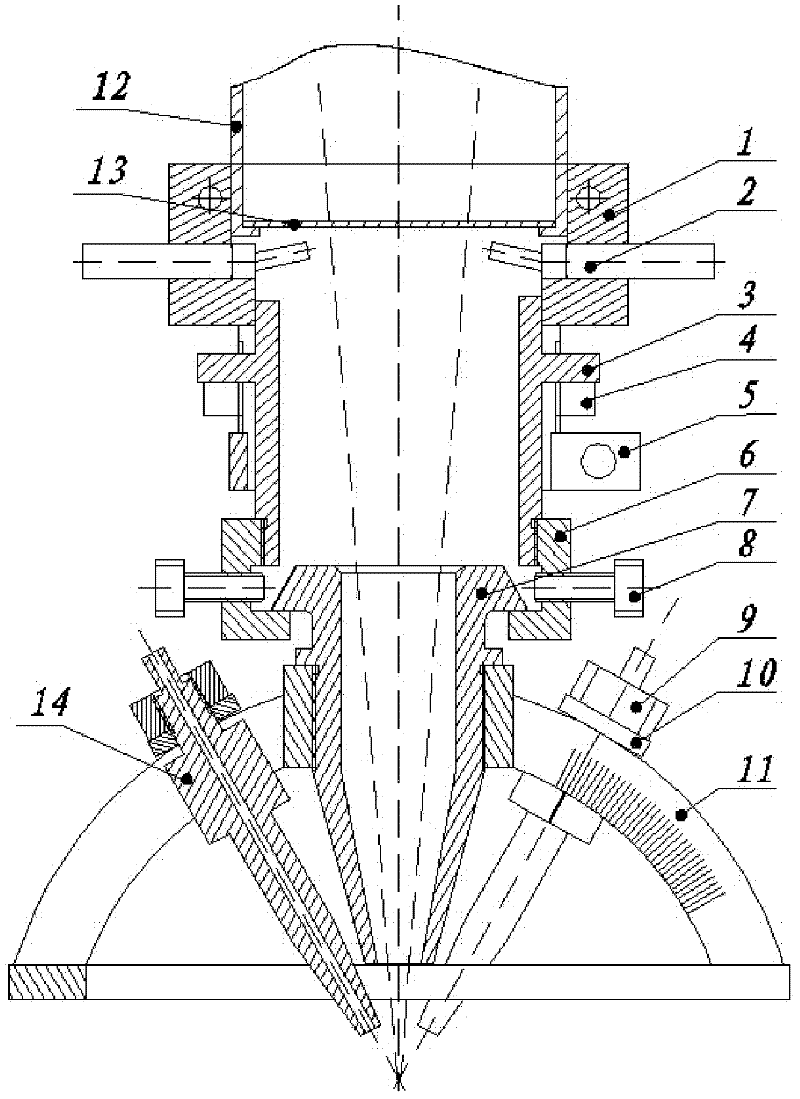

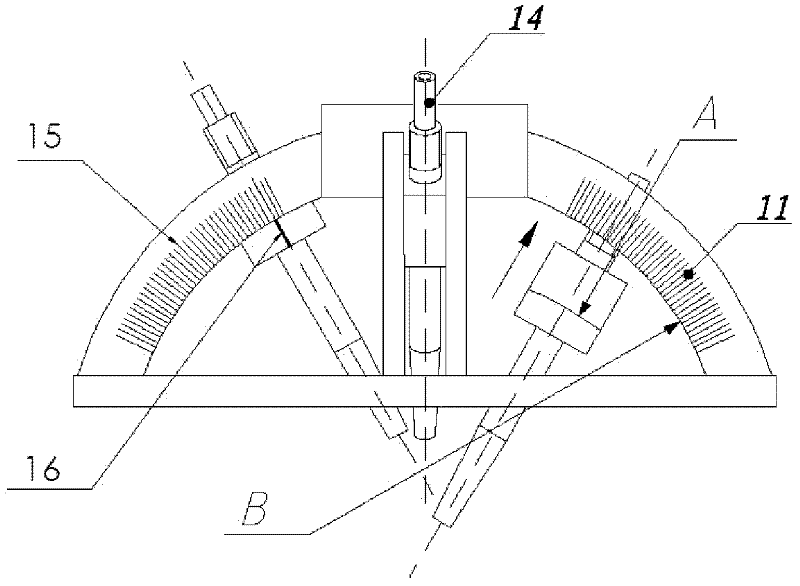

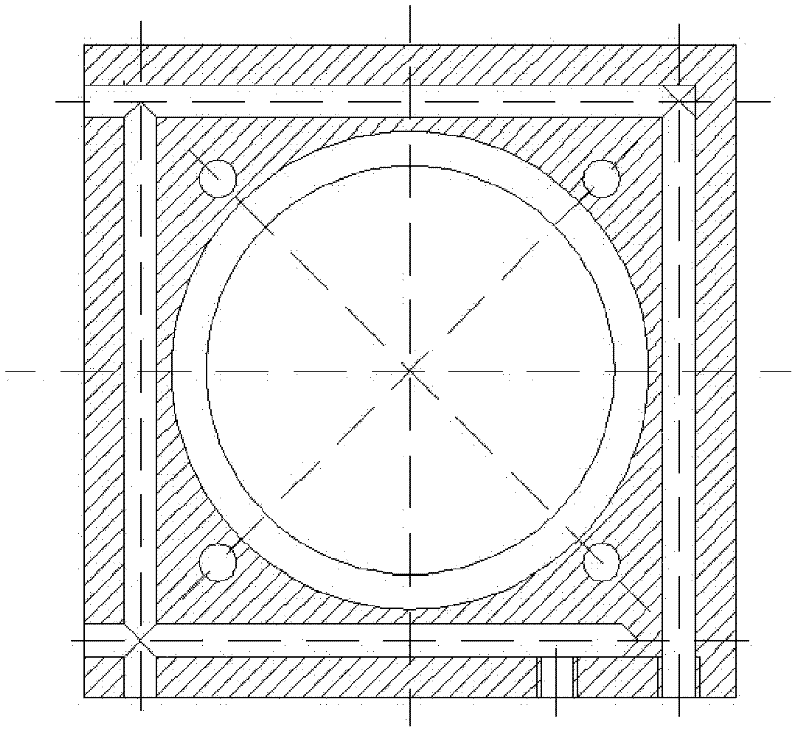

[0026] like figure 1 As shown, an angle-adjustable four-tube powder feeding nozzle for laser direct forming includes upper, middle and lower parts, and the upper part includes an upper connecting sleeve 1, which is connected with the laser head 12 through four screws; protection; The mirror decontamination nozzle 2 is installed in the upper connecting sleeve 1 to prevent the protective lens 13 in the laser head 12 from being polluted by external dust. The middle part is composed of sliding sleeve 3, powder defocus adjustment nut 4, locking sleeve 5, centering device 6 and centering screw 8, mainly to realize the adjustment of powder defocus amount and coaxiality, to ensure that powder enters accurately. In the molten pool, the sliding sleeve 3 can slide in the groove of the upper connecting sleeve 1, and when it reaches an appropriate position, the locking sleeve 5 fixes it. The lower part is composed of a conical laser sleeve 7, a rail frame 11, a powder spraying tube 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com