High-corrosion-resistant and wear-resistant coating and preparation method thereof

A wear-resistant coating and corrosion-resistant technology, applied in coatings, anti-corrosion coatings, polyether coatings, etc., can solve the problem of neglecting the combination of different base coatings and surface coatings, shortening the coating time, and improving corrosion resistance. Good friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

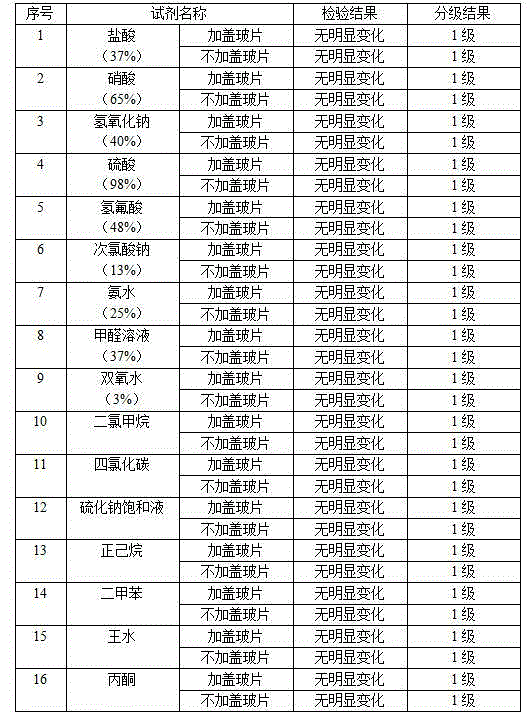

Image

Examples

Embodiment 1

[0028] Embodiment 1, high corrosion-resistant and wear-resistant coating of the present invention and preparation method thereof

[0029] Basic coating formula: polyether ketone 55%, ethylene-tetrafluoroethylene copolymer 25%, phenolic modified epoxy resin 14%, methylphenyl silicone resin 4.7%, polydimethylsiloxane 0.2%, octyl Phenol polyoxyethylene ether 1.0% and polyoxypropylene glyceryl ether 0.1%.

[0030] Surface coating formula: polyether ketone 12%, ethylene-tetrafluoroethylene copolymer 81%, nano-titanium dioxide 5.0%, octylphenol polyoxyethylene ether 1.0%, polyacrylate 0.2%, polyoxypropylene glyceryl ether 0.1% and Pigment 0.7%.

[0031] Preparation:

[0032] Preparation of base coating: pre-mix each component in a high-speed mixer, and then transport to a melt extrusion mixer. Each component is uniformly dispersed at 100°C and partially melted and mixed, then pressed into tablets, and cooled to 0°C Crushed, and then sieved after air classification and grinding...

Embodiment 2

[0035] Embodiment 2, high corrosion-resistant and wear-resistant coating of the present invention and preparation method thereof

[0036] Basic coating formula: polyether ketone 50%, ethylene-tetrafluoroethylene copolymer 20%, alicyclic epoxy resin 20%, methyl silicone resin 8.0%, polyacrylate 0.4%, octylphenol polyoxyethylene ether 1.2 % and polyoxypropylene glyceryl ether 0.4%.

[0037] Surface coating formula: polyether ketone 8%, ethylene-tetrafluoroethylene copolymer 85%, nano-titanium dioxide 4.0%, octylphenol polyoxyethylene ether 1.4%, polydimethylsiloxane 0.4%, polyoxypropylene glycerin Ether 0.2% and Pigment 1.0%.

[0038] Preparation:

[0039] Preparation of base coating: pre-mix each component in a high-speed mixer, and then transport it to a melt extrusion mixer, so that each component is uniformly dispersed at 120°C and partially melted and mixed, then pressed into tablets, and cooled to 0°C Finally, it is crushed, then sieved after air classification, gri...

Embodiment 3

[0042] Embodiment 3, high corrosion-resistant and wear-resistant coating of the present invention and preparation method thereof

[0043] Basic coating formula: polyether ketone 60%, ethylene-chlorotrifluoroethylene copolymer 23%, phenolic modified epoxy resin 10%, methylphenyl silicone resin 6.0%, polydimethylsiloxane 0.2%, octyl Base phenol polyoxyethylene ether 0.7% and polyoxypropylene glyceryl ether 0.1%.

[0044] Surface coating formula: polyether ketone 16%, ethylene-chlorotrifluoroethylene copolymer 75%, nano-titanium dioxide 7.0%, octylphenol polyoxyethylene ether 1.0%, polyacrylate 0.1%, polyoxypropylene glyceryl ether 0.4% and pigment 0.5%.

[0045] Preparation:

[0046] Preparation of the base coating: pre-mix the components in a high-speed mixer, and then transport them to the melt extrusion mixer, so that the components are uniformly dispersed at 90°C and partially melted and mixed, then pressed into tablets, and cooled to 0°C After crushing, air classific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wear value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com