Ultrafine dry powder cold gas sol fire extinguishing device

An ultra-fine dry powder, cold aerosol technology, applied in fire rescue and other directions, can solve long-term problems, such as grouting sand injection fire extinguishing method takes a week or even several weeks, fire extinguishing method is low in efficiency, etc., to achieve simple structure and manufacturing cost. Low, easy installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

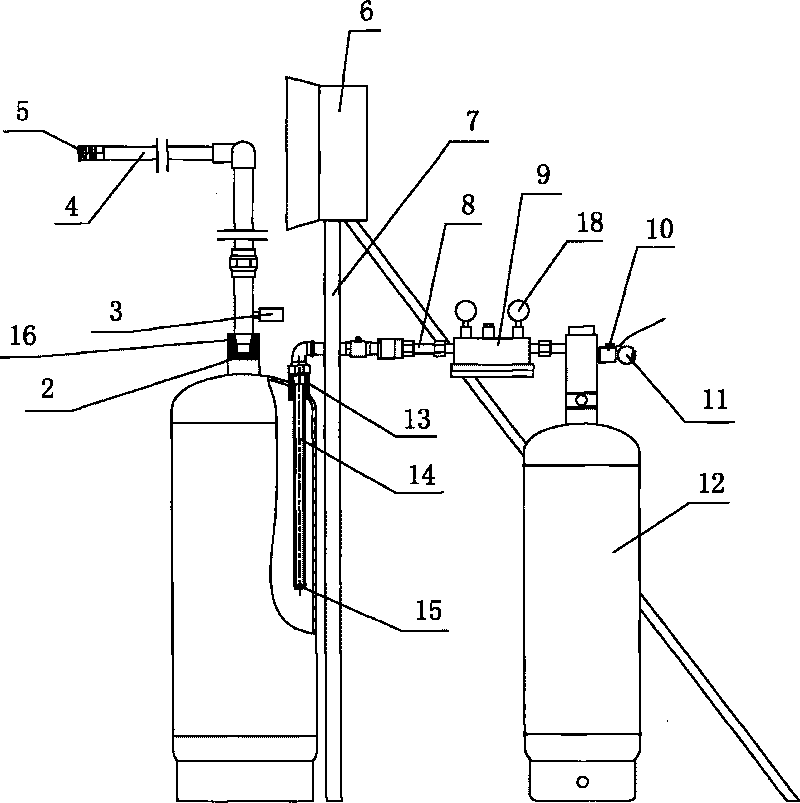

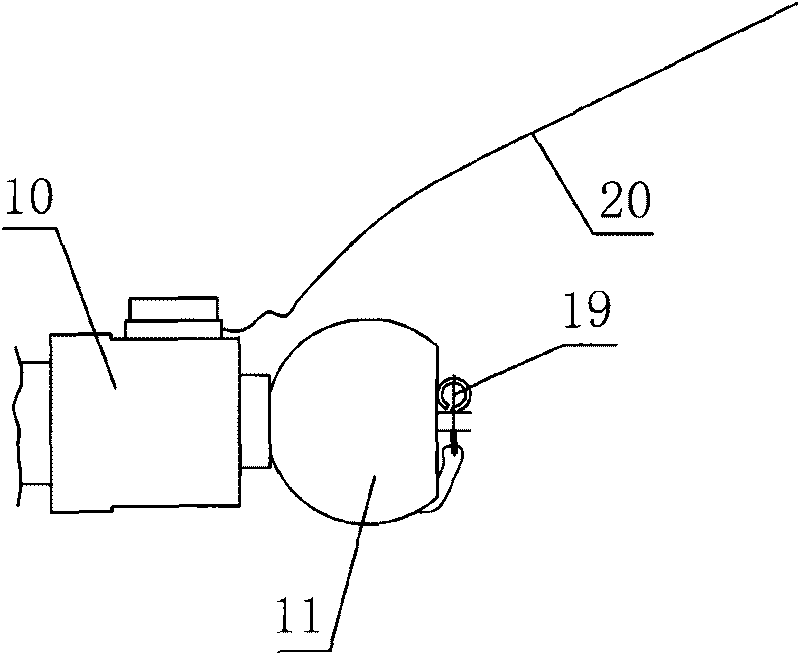

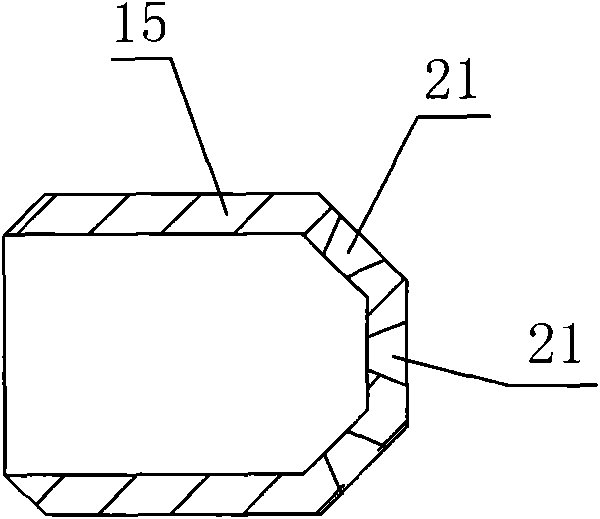

[0040] Such as figure 1 , Figure 6Shown, the present invention comprises the storage container 1 that has air inlet and powder spraying port and the interior is equipped with superfine dry powder fire extinguishing agent, the ultrafine dry powder spraying device that is connected with described powder spraying port and with described air inlet Sealed connection of high-pressure gas drive. The ultra-fine dry powder spraying device comprises a powder spray tube 4 that is installed on the powder spray port and communicates with the inside of the storage container 1, an ultra-fine dry powder outlet nozzle 5 that is installed on the other end of the powder spray tube 4, and is arranged on the spray tube. Inside the powder pipe 4 and under the pressure-free state, the dry powder spraying sealing diaphragm 2 that automatically and temporarily closes the powder spraying channel in the powder spraying pipe 4 and is arranged behind the outlet of the ultrafine dry powder outlet nozzle ...

Embodiment 2

[0048] Such as Figure 7 As shown, in this embodiment, the difference from Embodiment 1 is that the powerful axial flow fan 6 is arranged in front of the outlet of the superfine dry powder outlet nozzle 5. The powerful axial flow fan 6 "suctions" the superfine dry powder cold aerosol fire extinguishing agent to the distant fire zone. In this embodiment, the rest of the structures, connections and working principles are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com