A new type of mixer

A mixer and a new type of technology, applied in mixer accessories, mixers with rotary mixing devices, mixers, etc., can solve the problems of easy entry of dust into the product, difficult movement of materials, affecting product quality, etc., to improve mixing efficiency and convenience. The effect of investing in and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

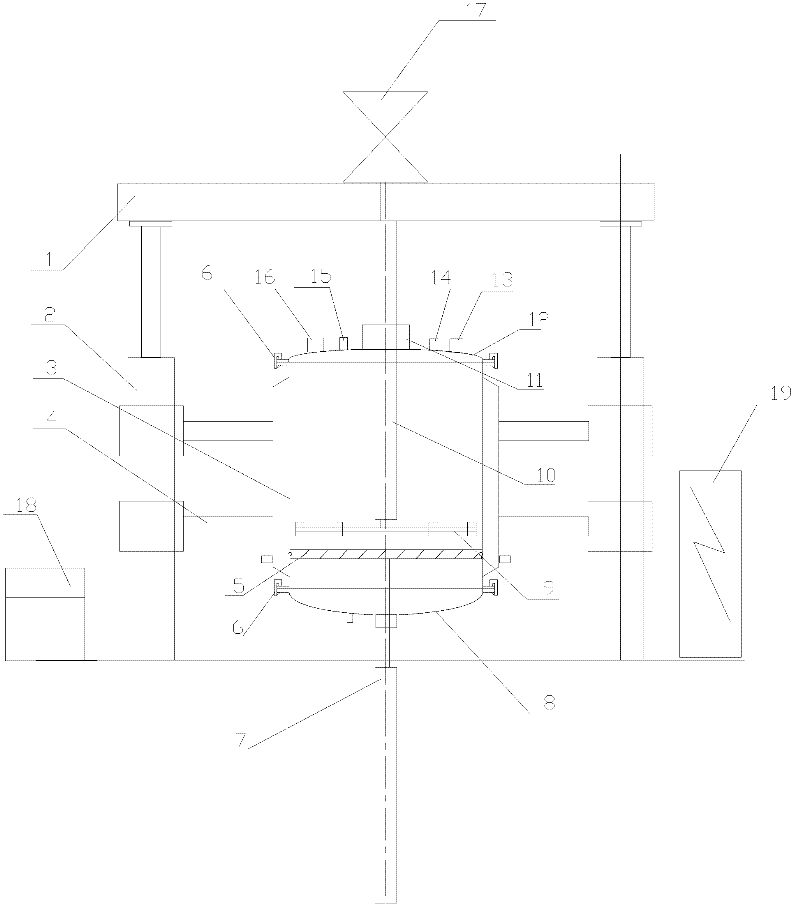

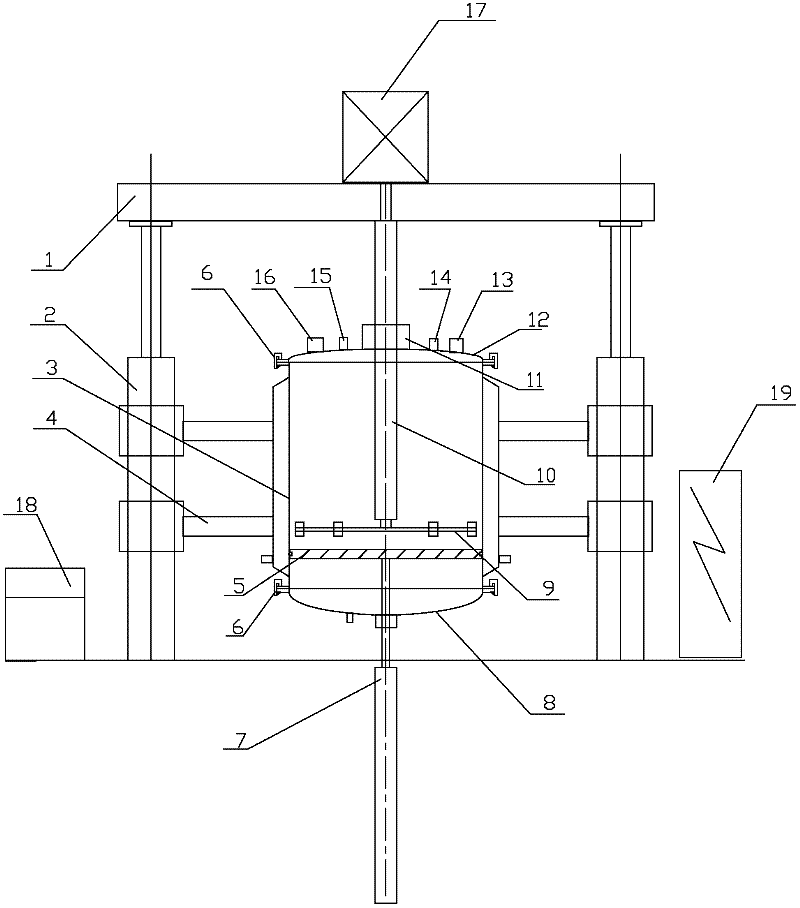

[0019] See figure 1 , which is a schematic structural view of the novel mixer in the present invention.

[0020] The novel agitator of the present invention comprises a tank body 3, a stirring paddle 9, a first elevating mechanism and a second elevating mechanism, the tank body 3 is installed and fixed by a tank body bracket 4, and the agitating paddle 9 is driven on the tank body by a power machine 17 through a transmission shaft 10 3 Internal rotation to stir the material. The first lifting mechanism drives the stirring paddle 9 to move up and down in the tank body 3 , and the second lifting mechanism drives the pressure plate 5 to move up and down in the tank body 3 , and the pressure plate 5 is below the stirring paddle 9 .

[0021] The first lifting mechanism includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com