Clothes aroma-retaining bead and preparation method thereof

A technology for fragrance beads and clothing, applied in the direction of washing composition fragrances, chemical instruments and methods, detergent compositions, etc., can solve the problems of inability to add surfactants, etc., achieve good anti-redeposition performance, long-lasting fragrance, and good fragrance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method for clothing fragrance beads, comprising the following steps:

[0060] S1. Add polyethylene glycol and non-ionic surfactant into a stirring container, heat to 75-80°C, and stir until it is uniformly liquid.

[0061] S2. Add additives except liquid essence and microcapsule essence to the stirring container under heat preservation condition, stir and disperse evenly.

[0062] S3. Continue to add liquid essence and microcapsule essence to the stirring container at a constant speed under heat preservation conditions, and stir evenly.

[0063] S4. Pass the mixture in the mixing container into the granulation equipment for granulation, and pack the granules after they are solidified and cooled.

[0064] Option 2: A fragrance-retaining beads for clothing, comprising the following components in mass percentage:

[0065] Non-ionic surfactant modified polyethylene glycol 50-90%,

[0066] Liquid essence 1~10%,

[0067] Microcapsule essence 1-10%,

[0068]...

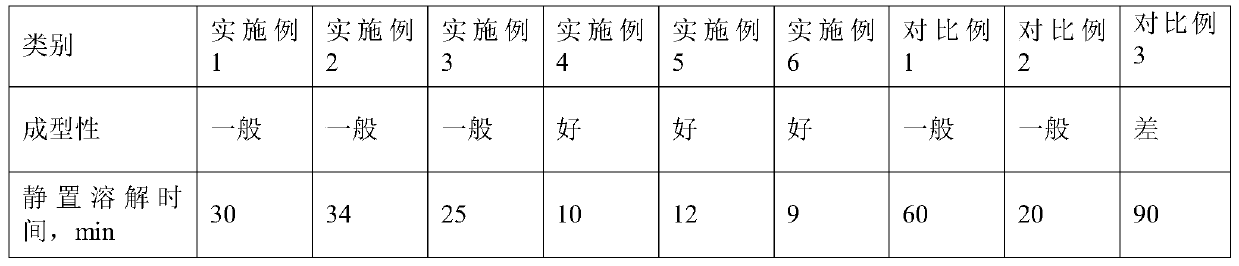

Embodiment 1

[0083] A kind of clothing fragrance beads, comprising the following components by mass fraction:

[0084] raw material Mass fraction / % Fatty alcohol polyoxyethylene ether 50 10 polyethylene glycol 6000 73 Acrylic acid homopolymer 5.9 liquid fragrance 8 Microcapsule flavor 3 dye 0.1

[0085] A clothing fragrance beads, its preparation method is as follows:

[0086] S1. Add the polyethylene glycol and non-ionic surfactant in the formula amount into the stirring pot, heat to 75-80°C, and stir until it is uniformly liquid;

[0087] S2. Add the formula amount of detergent additives and dyes to the mixing pot under heat preservation conditions, and stir to make them disperse evenly;

[0088] S3. Continue to add the liquid essence and the microcapsule essence of the formula to the stirring pot at a constant speed under the heat preservation condition, and stir evenly;

[0089] S4. Pass the mixed material in the stirring pot into th...

Embodiment 2

[0091] A kind of clothing fragrance beads, comprising the following components by mass fraction:

[0092] raw material Mass fraction / % Fatty alcohol polyoxyethylene ether 80 10 fatty acid methyl ester ethoxylate 5 polyethylene glycol 8000 60 4A zeolite 10 Acrylic acid-maleic acid copolymer 4.9 liquid fragrance 6 Microcapsule flavor 4 dye 0.1

[0093] A clothing fragrance beads, its preparation method is as follows:

[0094] S1. Add the polyethylene glycol and non-ionic surfactant in the formula amount into the stirring pot, heat to 75-80°C, and stir until it is uniformly liquid;

[0095] S2. Add the formula amount of detergent additives and dyes to the mixing pot under heat preservation conditions, and stir to make them disperse evenly;

[0096] S3. Continue to add the liquid essence and the microcapsule essence of the formula to the stirring pot at a constant speed under the heat preservation condition, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com