Seawater desalination composite membrane for producing hydrogen-rich direct drinking water and preparation method of seawater desalination composite membrane

A direct-drinking water and composite membrane technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of low hydrogen content, poor separation effect of seawater desalination, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

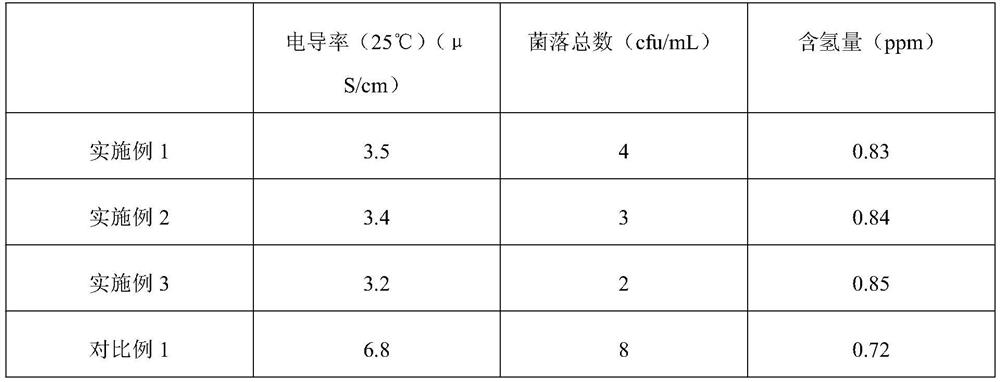

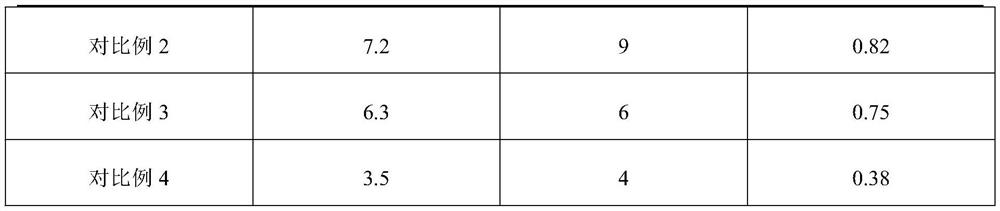

Examples

Embodiment 1

[0041] A method for preparing a seawater desalination composite membrane for producing hydrogen-rich direct drinking water, the specific steps are as follows:

[0042] (1) Using 2-ethylhexyl acrylate and dimethyl styrene as main monomers, adding organically modified lithium-titanium dioxide-silicon dioxide nanomaterials, and polymerizing to obtain an acrylic resin;

[0043] (2) Then, stir and mix the acrylic resin with tetraethyl orthosilicate, butyl titanate, and N-methylpyrrolidone, add water, adjust the pH=5, stir the hydrolysis reaction, then add polyethersulfone micropowder and 1- Butyl-3-methylimidazolium tetrafluoroborate, stirring and dispersing evenly to obtain a slurry;

[0044] (3) coating the slurry on a smooth substrate, drying after rolling, curing, and peeling off to obtain a base film;

[0045] (4) Finally, evenly spray the surface paint on one side of the base film, let it stand for aging, and dry to obtain the described a kind of seawater desalination compos...

Embodiment 2

[0066] A method for preparing a seawater desalination composite membrane for producing hydrogen-rich direct drinking water, the specific steps are as follows:

[0067] (1) Using 2-ethylhexyl acrylate and dimethyl styrene as main monomers, adding organically modified lithium-titanium dioxide-silicon dioxide nanomaterials, and polymerizing to obtain an acrylic resin;

[0068] (2) Then, stir and mix the acrylic resin with tetraethyl orthosilicate, butyl titanate, and N-methylpyrrolidone, add water, adjust the pH=6, stir the hydrolysis reaction, then add polyethersulfone micropowder and 1- Butyl-3-methylimidazolium tetrafluoroborate, stirring and dispersing evenly to obtain a slurry;

[0069] (3) coating the slurry on a smooth substrate, drying after rolling, curing, and peeling off to obtain a base film;

[0070] (4) Finally, evenly spray the surface paint on one side of the base film, let it stand for aging, and dry to obtain the described a kind of seawater desalination compos...

Embodiment 3

[0091] A method for preparing a seawater desalination composite membrane for producing hydrogen-rich direct drinking water, the specific steps are as follows:

[0092] (1) Using 2-ethylhexyl acrylate and dimethyl styrene as main monomers, adding organically modified lithium-titanium dioxide-silicon dioxide nanomaterials, and polymerizing to obtain an acrylic resin;

[0093] (2) Stir and mix the acrylic resin with tetraethyl orthosilicate, butyl titanate, and N-methylpyrrolidone, add water, adjust the pH=5.5, stir the hydrolysis reaction, then add polyethersulfone micropowder and 1- Butyl-3-methylimidazolium tetrafluoroborate, stirring and dispersing evenly to obtain a slurry;

[0094] (3) coating the slurry on a smooth substrate, drying after rolling, curing, and peeling off to obtain a base film;

[0095] (4) Finally, evenly spray the surface paint on one side of the base film, let it stand for aging, and dry to obtain the described a kind of seawater desalination composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com