A stable NCO prepolymer, a preparing method thereof and use of the prepolymer

A prepolymer and stable technology, which is applied in the field of stable NCO prepolymer and its preparation, can solve the problems of limited storage time, high NDI activity, and difficulty in storage of prepolymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 332g of 1,5-naphthalene diisocyanate (NDI) was heated to 130°C to become a clear liquid, then 77g of cetyl alcohol was added for capping, and stirred for 30 minutes; 1000g of poly-ε-caprolactone polyol (PCL ) to 80°C to 100°C, add 50g of polyethylene wax, stir evenly with a high-speed mixer, the stirring speed is higher than 1000r / min, and stir for 20 to 40 minutes; control the speed by a metering pump, and poly-ε-caprolactone The mixture of polyol (PCL) and polyethylene wax is added to the mixture of NDI and cetyl alcohol at one time, and then stirred at high speed with a high-speed mixer, the stirring speed is higher than 2000r / min, and the stirring time is shorter than 10 minutes. After the stirring is completed Keep the temperature of the mixed solution at 90-120°C, then pour the mixed solution into containers and pack it for storage.

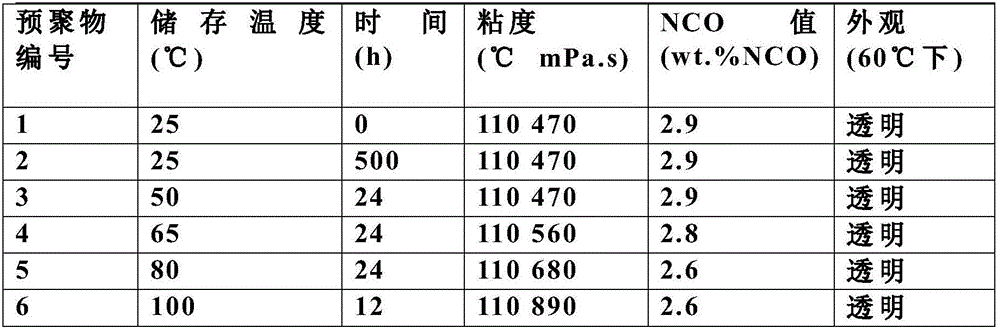

[0032] After the prepolymer was divided into several groups of samples, the samples were tested at different storage temperatures. ...

Embodiment 2

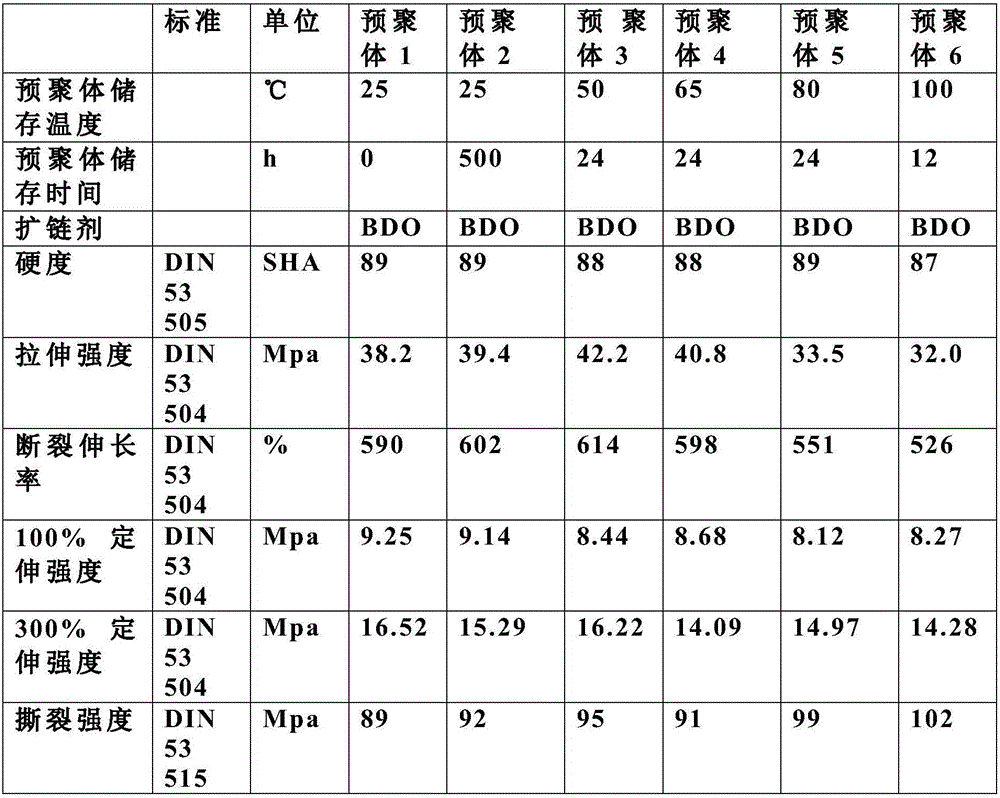

[0036] Heat the prepolymer in Example 1 to 120°C, and after degassing, mix it with 75g of 1,4-butanediol for chain extension, then pour it into a mold coated with a release agent, and then put it into a 130 Cure in a blast oven at ℃ for 2 hours and then release the mold, and then put it in the oven for 20 hours and then take it out to test its performance.

[0037] The performance test result of each test sample in table 2 embodiment 2

[0038]

Embodiment 3

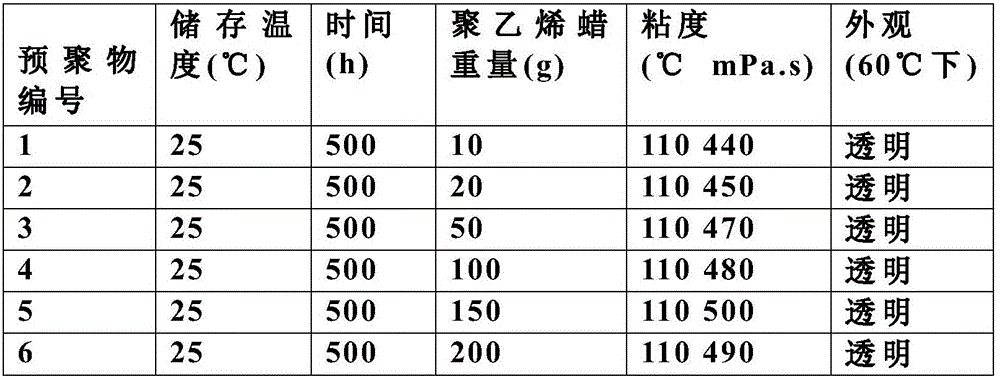

[0040] 332g of 1,5-naphthalene diisocyanate (NDI) was heated to 130°C to become a clear liquid, then 77g of cetyl alcohol was added for capping, and stirred for 30 minutes; 1000g of poly-ε-caprolactone polyol ( PCL) is heated to 80°C-100°C, adding polyethylene wax of different weights, stirring evenly with a high-speed mixer, the stirring speed is higher than 1000r / min, and stirring for 20-40 minutes; the speed is controlled by a metering pump, and the poly-ε-hexyl The mixture of lactone polyol (PCL) and polyethylene wax is added to the mixture of NDI and cetyl alcohol at one time, and then stirred at a high speed with a high-speed mixer, the stirring speed is higher than 2000r / min, and the stirring time is shorter than 10 minutes. After completion, the temperature of the mixed solution is 90-120° C., and then the mixed solution is poured into containers and packaged for storage.

[0041] After the prepolymer is divided into several groups of samples, the samples are tested at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com