Simple preparation method of aluminate electron-emission substance for hot cathode

A technology of electron emission and aluminate, which is applied in the preparation of alkaline earth metal aluminate/alumina/hydroxide, parts of discharge tube/lamp, circuits, etc., can solve the problem of large aluminate particle size and inconsistent phase Single, multi-emission performance and other issues, to achieve the effect of single phase, simple preparation process, and good emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

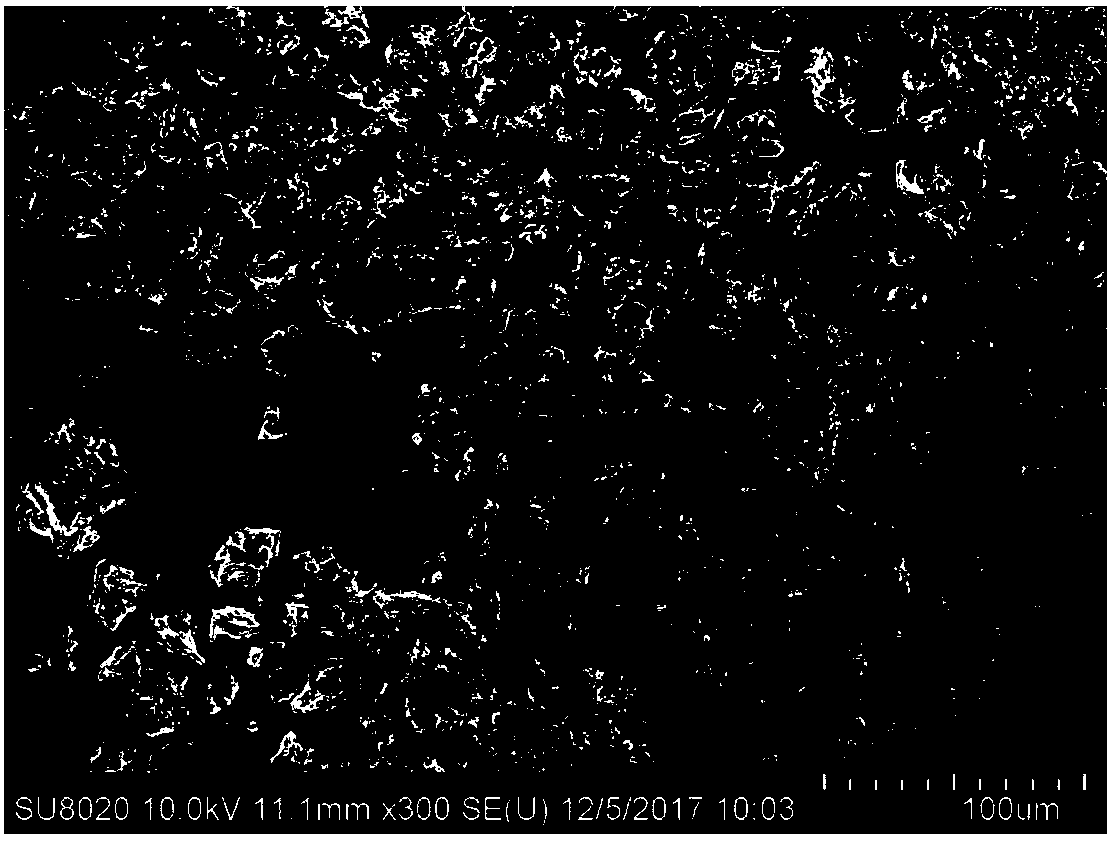

[0027] Weigh 52.3g of Ba(NO 3 ) 2 , 11.8g of Ca(NO 3 ) 2 4H 2 0 and 37.5g of Al(NO 3 ) 3 9H 2 O and other raw materials, the molar ratio of which is 4:1:2, was dissolved in 2L of deionized water to form a nitrate solution, and 102.3g of EDTA was weighed and dissolved in 100ml of ammonia water. Put the nitrate solution in a water bath and heat it up to 80°C. At the same time, slowly add the EDTA solution into it, heat and stir continuously to form a sol, place it in an oven at 120°C to remove water to form a xerogel, and then put it in a horse Decompose in a Furnace, the decomposition temperature is 800°C, and keep warm for 4h. The morphology of the obtained precursor powder is as follows figure 1 As shown, after being ground, it is passed through a 200-mesh standard sieve, and then it is put into a high-temperature hydrogen furnace for sintering in a hydrogen environment. The sintering temperature is set at 1400°C, and the aluminate is obtained after holding for 4 hour...

Embodiment 2

[0029] Weigh 52.3g of Ba(NO 3 ) 2 , 11.8g of Ca(NO 3 ) 2 4H 2 0 and 37.5g of Al(NO 3 ) 3 9H 2O and other raw materials, the molar ratio of which is 4:1:2, was dissolved in 2L of deionized water to form a nitrate solution, and 102.3g of EDTA was weighed and dissolved in 100ml of ammonia water. Put the nitrate solution in a water bath and heat it up to 80°C. At the same time, slowly add the EDTA solution into it, heat and stir continuously to form a sol, place it in an oven at 120°C to remove water to form a xerogel, and then put it in a horse Decompose in a Furnace, the decomposition temperature is 800°C, and keep warm for 4h. The obtained precursor powder was ground and passed through a 200-mesh standard sieve, and then put into a high-temperature hydrogen furnace for sintering in a hydrogen environment. The sintering temperature was set at 1500°C, and after holding for 4 hours, the aluminate was obtained. The phase analysis was as follows: Figure 4 shown. Cathode im...

Embodiment 3

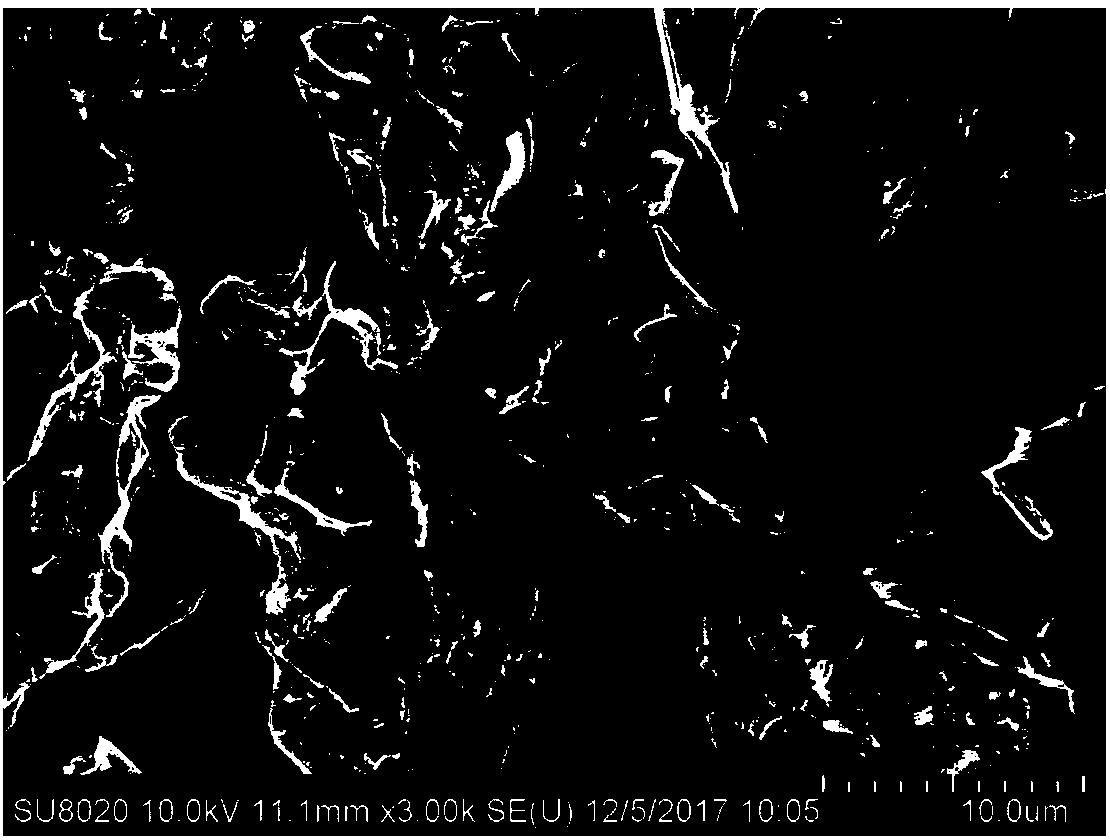

[0031] Weigh 52.3g of Ba(NO 3 ) 2 , 7.9g of Ca(NO 3 ) 2 4H 2 0 and 50.0g of Al(NO 3 ) 3 9H 2 O and other raw materials, the molar ratio of which is 6:1:4, was dissolved in 2L of deionized water to form a nitrate solution, and 102.3g of EDTA was weighed and dissolved in 100ml of ammonia water. Put the nitrate solution in a water bath and heat it up to 80°C. At the same time, slowly add the EDTA solution into it, heat and stir continuously to form a sol, place it in an oven at 120°C to remove water to form a xerogel, and then put it in a horse Decompose in a Furnace, the decomposition temperature is 800°C, and keep warm for 4h. The obtained precursor powder was ground and passed through a 200-mesh standard sieve, and then put into a high-temperature hydrogen furnace for sintering in a hydrogen environment. The sintering temperature was set at 1400°C. After holding for 4 hours, the aluminate was obtained. Its microscopic appearance is as follows: image 3 shown. Cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com