Silicon carbide fiber production method using acid soluble dealuminized fly ash and carbide slag

A xonotlite and fly ash technology, applied in the field of xonotlite fiber production, can solve the problems of large impact on resources and environment, high production energy consumption and cost, long hydrothermal reaction time, etc., and achieve phase-free Impurities, saving resources, the effect of large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

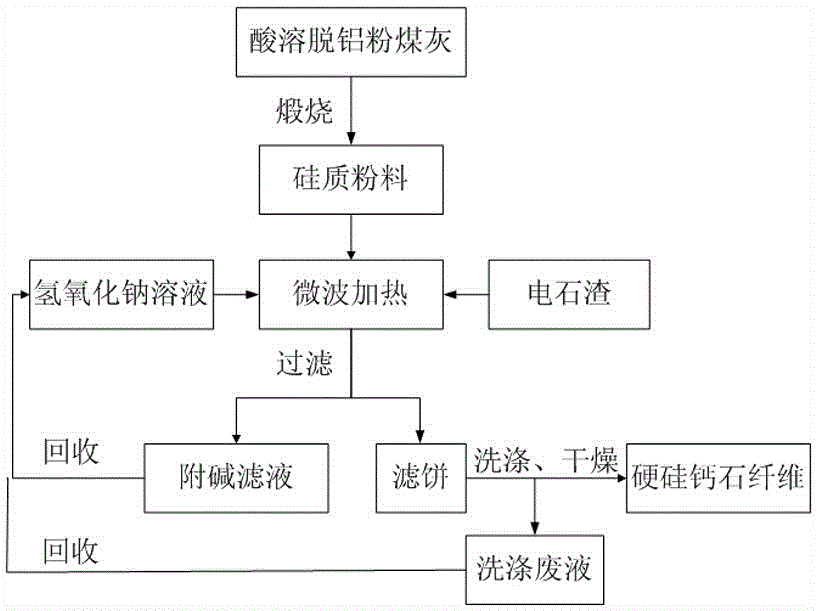

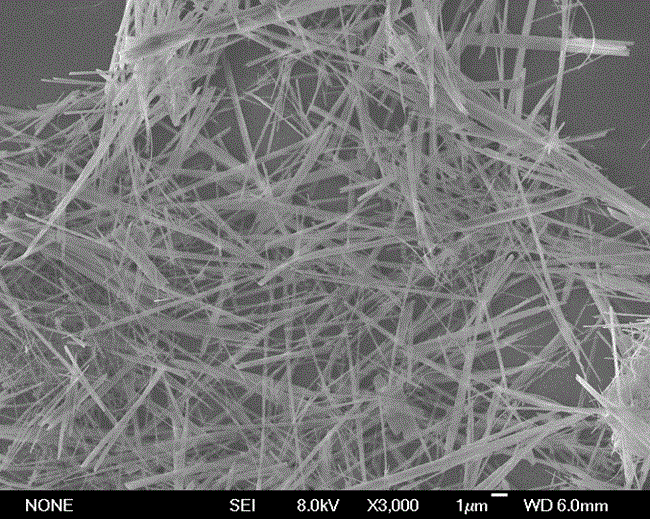

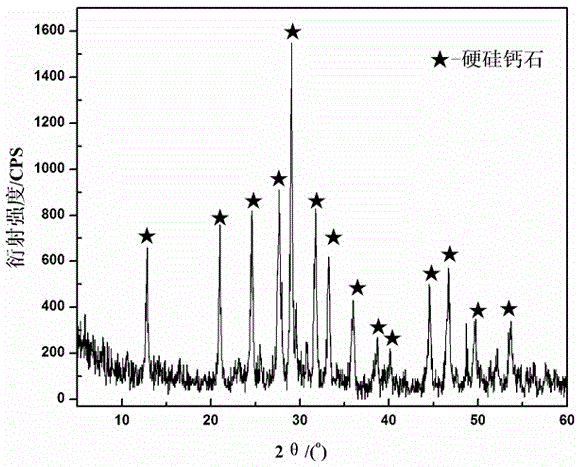

[0033] Xonotlite fibers are produced from acid-soluble dealuminated fly ash and carbide slag, in which acid-soluble dealuminated fly ash contains 60% SiO 2 , 14.2% Al 2 o 3 , 1.74% CaO, 20.6% unburned carbon and 0.57% Na 2 O; Carbide slag contains 60% CaO, 4.34% SiO 2 , 2.24% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: put the acid-soluble dealuminated fly ash into the muffle furnace and calcined at 400°C for 2 hours to obtain the siliceous powder; the siliceous powder, carbide slag and sodium hydroxide solution with a mass concentration of 6% were mixed with Si:Ca: The molar ratio of Na is 1:1:1.4. After mixing evenly, microwave heating to 150°C and keep it warm for 4 hours. After the reaction is completed, filter the mixed slurry to obtain a filter cake and alkali filtrate. Wash the filter cake and dry it at 100°C for 3 hours. Xonotlite fibers are obtained; the filter cake washing waste liquid and the alkali filtrate are r...

Embodiment 2

[0036] Xonotlite fibers are produced from acid-soluble dealuminated fly ash and carbide slag, in which acid-soluble dealuminated fly ash contains 64% SiO 2 , 13.25% Al 2 o 3 , 0.84% CaO, 20.4% unburned carbon and 0.57% Na 2 O; Carbide slag contains 65% CaO, 3.34% SiO 2 , 2.04% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: put the acid-soluble dealuminated fly ash into the muffle furnace and calcined at 450°C for 1.5h to obtain the siliceous powder; put the siliceous powder, carbide slag and 5% sodium hydroxide solution in the form of Si:Ca: The Nar ratio is 1:0.95:1.2, and the ingredients are mixed evenly. After the mixture is uniform, the microwave is heated to 180°C for 5 hours. After the reaction is completed, the mixed slurry is filtered to obtain the filter cake and the filtrate with alkali. The filter cake is washed and dried at 100°C for 3 hours. Xonotlite fibers are obtained; the filter cake washing waste liquid and ...

Embodiment 3

[0039] Xonotlite fibers are produced from acid-soluble dealuminated fly ash and carbide slag, in which acid-soluble dealuminated fly ash contains 59% SiO 2 , 13.25% Al 2 o 3 , 1.44% CaO, 20.4% unburned carbon and 0.52% Na 2 O; Carbide slag contains 59.9% CaO, 3.34% SiO 2 , 2.24% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: Put the acid-soluble dealuminated fly ash into a muffle furnace and calcinate at 500°C for 2.5 hours to obtain siliceous powder; put the siliceous powder, carbide slag, and 6% sodium hydroxide solution in the form of Si:Ca: The molar ratio of Na is 1:0.9:1.5. After mixing evenly, microwave heating to 160°C for 4 hours of heat preservation reaction; after the reaction is completed, filter the mixed slurry to obtain filter cake and alkali filtrate, wash the filter cake and dry at 105°C for 6 hours Xonotlite fibers are obtained; the filter cake washing waste liquid and the alkali filtrate are recovered and app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com