Solid solution type (Ti, Mo, Ta, Me) (C, N) nanopowder and preparing method thereof

A nano-powder and solid solution technology, applied in the field of composite materials, can solve the problems of inability to overcome the inability of metal carbides to be dissolved in solid solution, the product size is coarse and difficult to refine, and it is difficult to achieve solid solution powder. Complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a solid-solution type (Ti, Mo, Ta, Me) (C, N) nanopowder provided in an embodiment of the present invention comprises the following steps:

[0028] A method for preparing solid solution type (Ti, Mo, Ta, Me) (C, N) nanometer powder, comprising the following steps.

[0029] First of all, in the batching step, according to the composition of the solid solution, the oxides of Ti, Mo, Ta and Me elements are weighed as raw materials, and carbon black is used as the reducing agent and carbonizing agent, wherein the Me element is selected from W, Nb, Zr one or more.

[0030] The presence of Mo, Ta, W, Nb, Zr and other elements can effectively change the mechanical properties, mechanical properties, chemical properties, etc. of the powder, enhance the hardness, wear resistance, heat resistance, etc. of the product, and have good chemical stability properties and fracture toughness. Further preferably, W and Nb are selected as Me elements, and the produc...

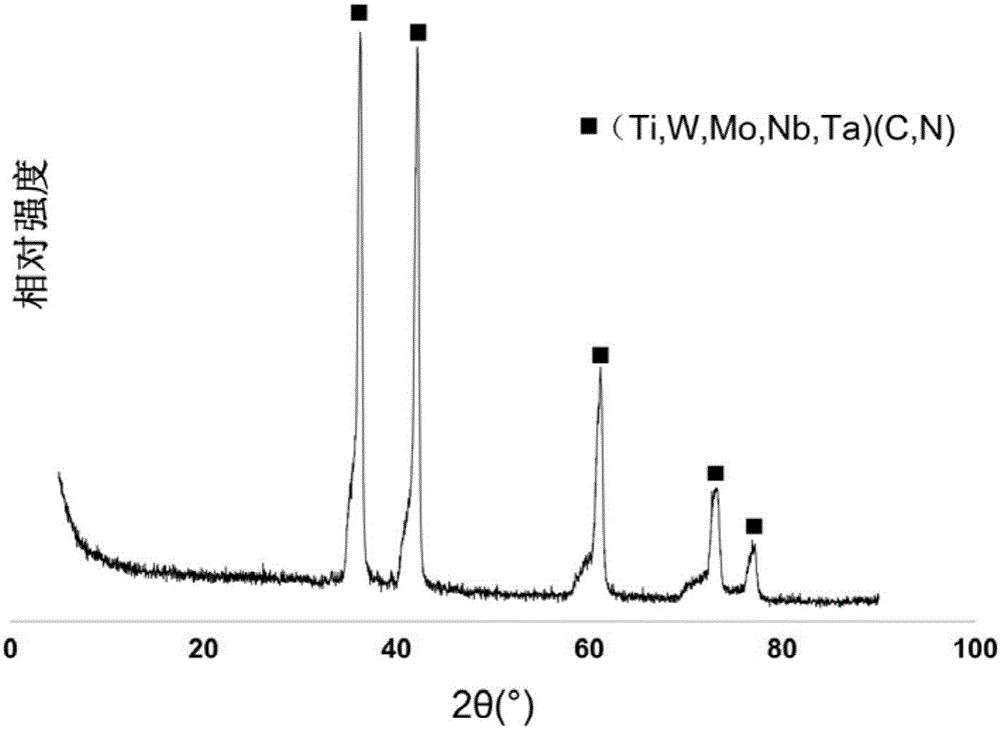

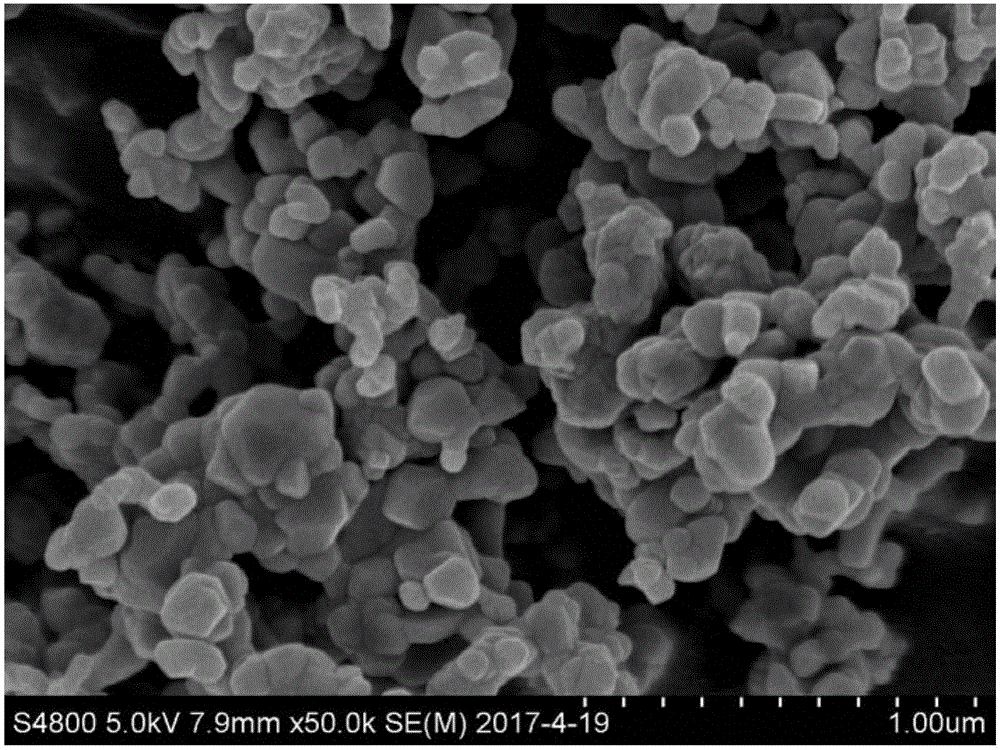

Embodiment 1

[0059] A solid solution type (Ti 0.82 W 0.07 Ta 0.02 Mo 0.05 Nb 0.04 ) (C 0.54 N 0.46 ) Nanopowder, which is prepared according to the following method.

[0060] Take 0.3~0.5μm TiO 2 , 0.5~0.8μm WO 3 、 Ta 2 o 5 、MoO 3 and Nb 2 o 5 The powder is used as the metal raw material, and spherical carbon black with a particle size of 100nm is used as the carbon source, and the compounding is carried out according to the ratio of the solid solution powder components. The mass ratio of the raw materials is controlled as follows: TiO 2 :MoO 3 :WO 3 :Nb 2 o 5 : Ta 2 o 5 :C=49.72:11.73:4.94:4.43:4.01:25.18.

[0061] Put the prepared raw materials into the zirconia ball mill tank, and perform raw material activation and mixing treatment on the planetary ball mill at 200r / min. During the mixing process, alcohol is used as the ball milling medium, and zirconia balls are used as ball milling balls. Add 4wt% of PEG-4000 (percentage relative to the total mass of the mixture) ...

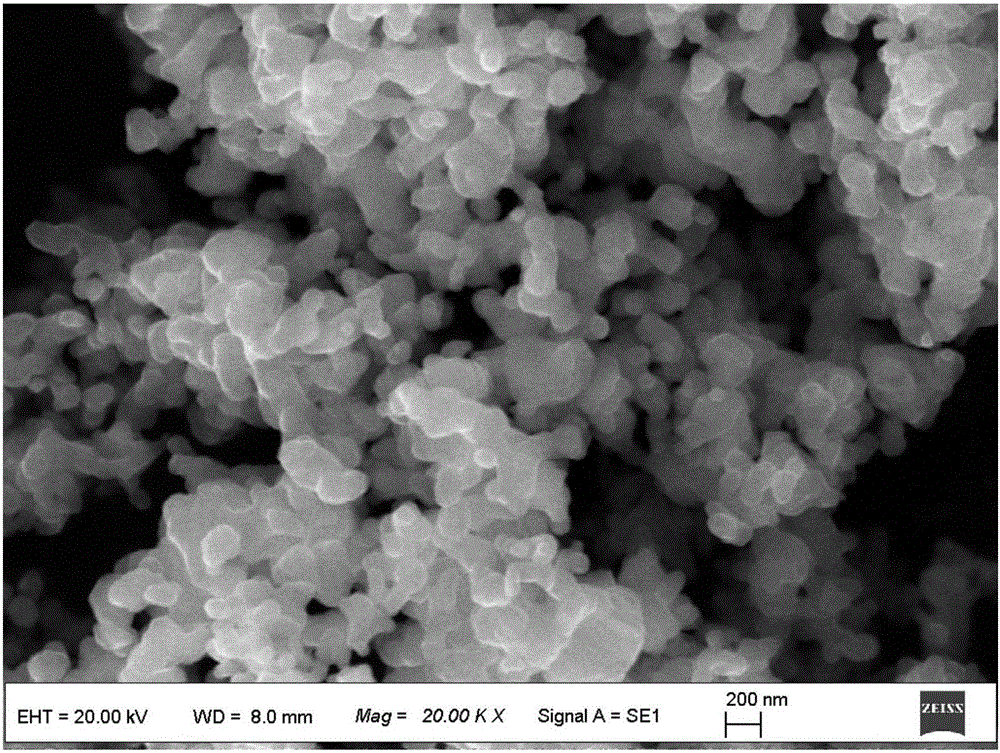

Embodiment 2

[0067] A kind of solid solution type Ti provided by this embodiment 0.82 W 0.07 Ta 0.02 Mo 0.05 Nb 0.04 )(C 0.54 N 0.46 ) nano powder, the difference between its preparation method and embodiment 1 is: reach the control to product C / N by adjusting the carbon content of raw material, the quality of raw material is equipped with: TiO 2 :MoO 3 :WO 3 :Nb 2 o 5 : Ta 2 o 5 :C=49.10:11.59:4.88:4.37:3.96:26.09. And after adjusting the reaction temperature in the system to 1150°C, control the N 2 The partial pressure is 1000-1500Pa, and the holding time is still 3 hours, and the solid solution (Ti 0.82 W 0.07 Ta 0.02 Mo 0.05 Nb 0.04 )(C 0.54 N 0.46 ) nano powder products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com