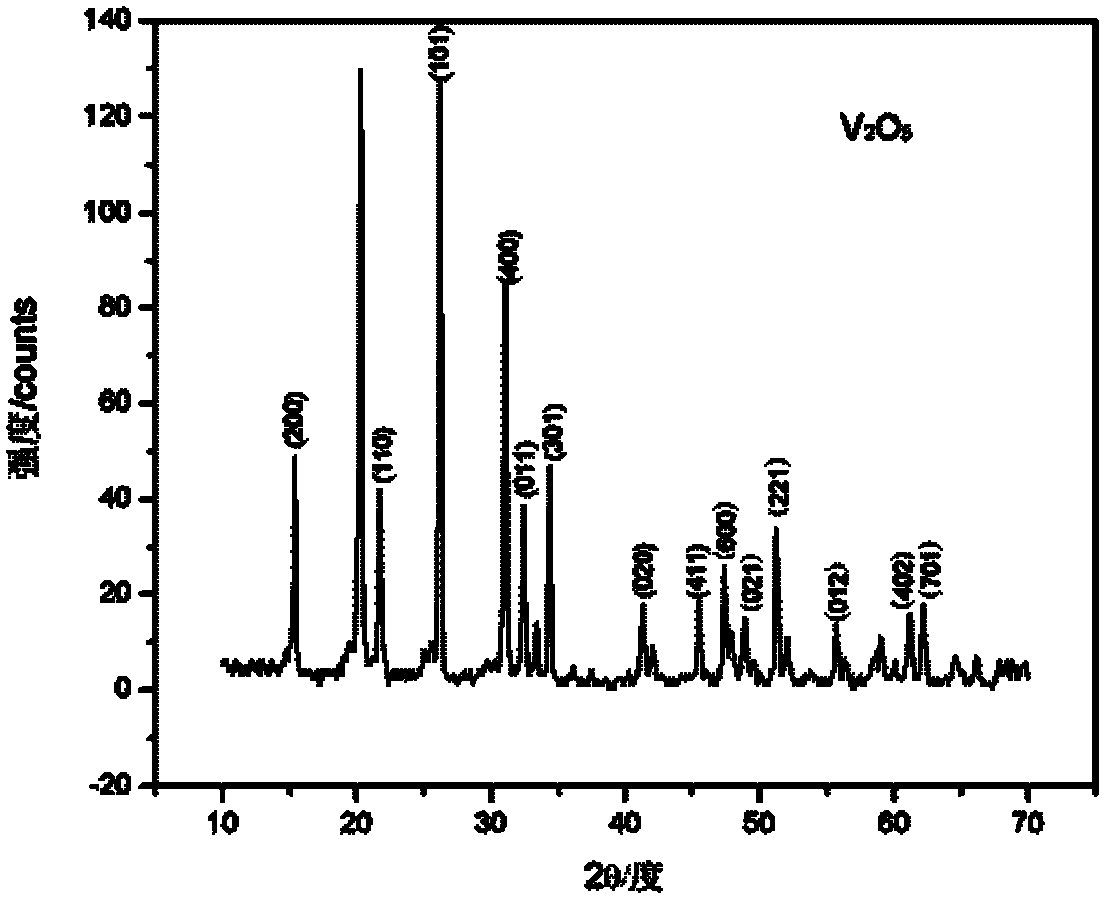

Method for preparing V2O5 nano-powders

A nano-powder, V2O5 technology, applied in the field of material science, can solve the problems of long experimental period, high requirements for experimental equipment, complex operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) First, add 20ml of deionized water and 2.34g of NH to the beaker 4 VO 3 While stirring, slowly add 3ml of ammonia water with a mass concentration of 8%, and continue to stir until the NH 4 VO 3 After completely dissolving, add 10ml dimethyl sulfoxide and stir evenly to obtain solution A;

[0014] 2) Place solution A in an ultrasonic generator with a water bath temperature of 70°C and an ultrasonic power of 200W, then slowly add 25ml of hydrogen peroxide solution with a mass concentration of 3% to it, and react for 5 hours to obtain a light orange-red suspension Liquid B;

[0015] 3) Centrifuge the suspension B at a speed of 4000r / min, wash it repeatedly with deionized water and isopropanol to obtain a light orange-red fine powder, soak the obtained powder in isopropanol, and Dry in an electric blast oven at 30°C for 8 hours to obtain V 2 o 5 Nano powder.

Embodiment 2

[0017] 1) First, add 30ml of deionized water and 2.34g of NH to the beaker 4 VO 3 While stirring, slowly add 45ml of ammonia water with a mass concentration of 5%, and continue to stir until the NH 4 VO 3 After completely dissolving, add 5ml dimethyl sulfoxide and stir evenly to obtain solution A;

[0018] 2) Place solution A in an ultrasonic generator with a water bath temperature of 50°C and an ultrasonic power of 400W, then slowly add 5ml of hydrogen peroxide solution with a mass concentration of 8% to it, and react for 2 hours to obtain a light orange-red suspension Liquid B;

[0019] 3) Centrifuge the suspension B at a speed of 4000r / min, wash it repeatedly with deionized water and isopropanol to obtain a light orange-red fine powder, soak the obtained powder in isopropanol, and Dry in an electric blast oven at 120°C for 1 hour to obtain V 2 o 5 Nano powder.

Embodiment 3

[0021] 1) First, add 40ml of deionized water and 2.34g of NH to the beaker 4 VO 3 While stirring, slowly add 5ml of ammonia water with a mass concentration of 3%, and continue to stir until the NH 4 VO 3 After completely dissolving, add 7ml dimethyl sulfoxide and stir evenly to obtain solution A;

[0022] 2) Place solution A in an ultrasonic generator with a water bath temperature of 55°C and an ultrasonic power of 300W, then slowly add 15ml of hydrogen peroxide solution with a mass concentration of 5% to it, and react for 4 hours to obtain a light orange-red suspension Liquid B;

[0023] 3) Centrifuge the suspension B at a speed of 4000r / min, wash it repeatedly with deionized water and isopropanol to obtain a light orange-red fine powder, soak the obtained powder in isopropanol, and Dry in an electric blast oven at 80°C for 5 hours to obtain V 2 o 5 Nano powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com