Garnet type solid solution magnetic dielectric functional medium ceramic material and preparation method thereof

A garnet-type, dielectric ceramic technology is applied in fixed capacitor dielectrics, fixed capacitors, and components of fixed capacitors. The effect of excellent microwave dielectric properties, single phase, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

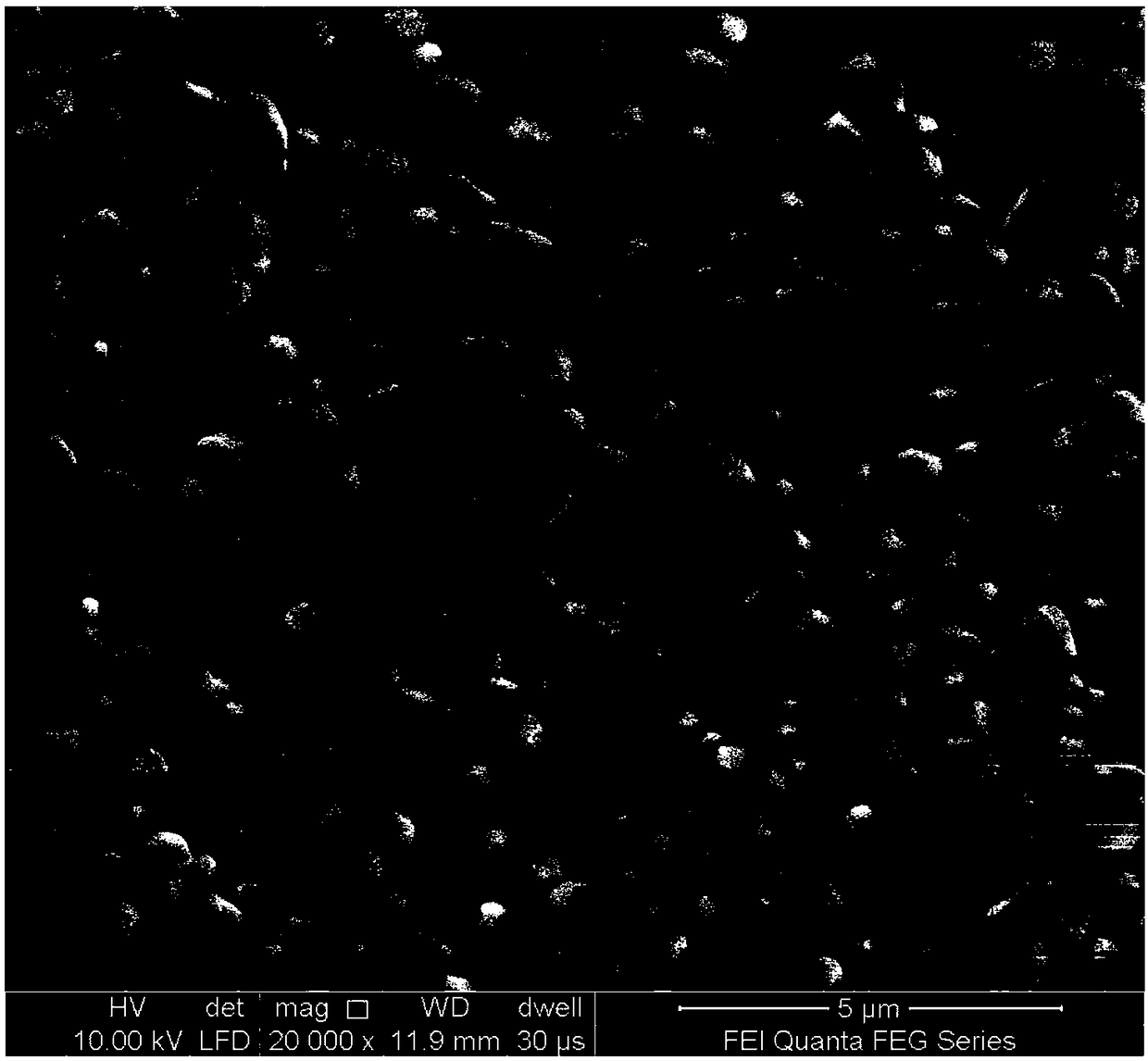

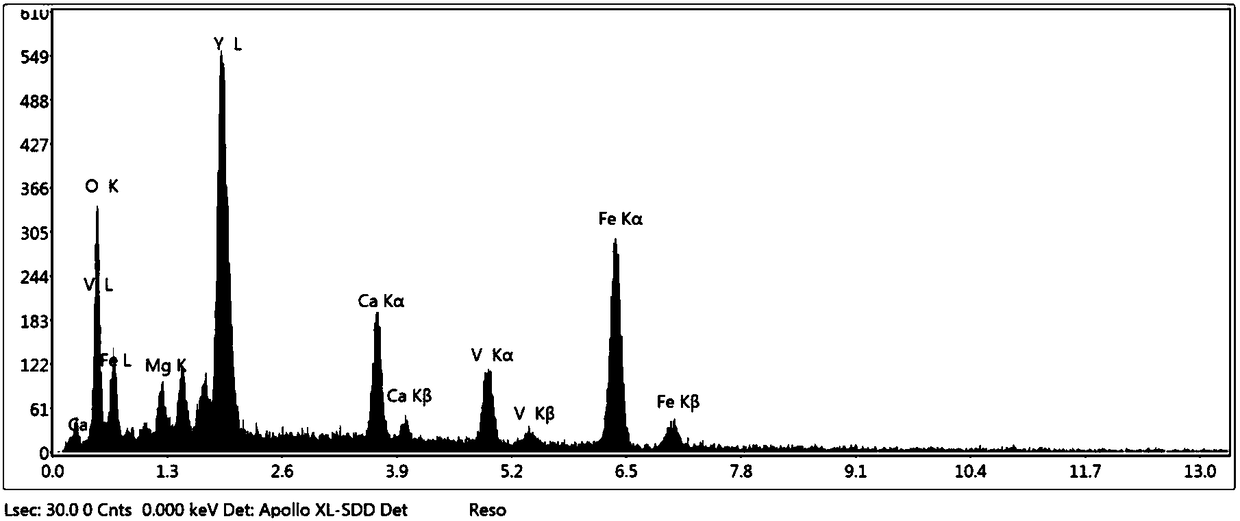

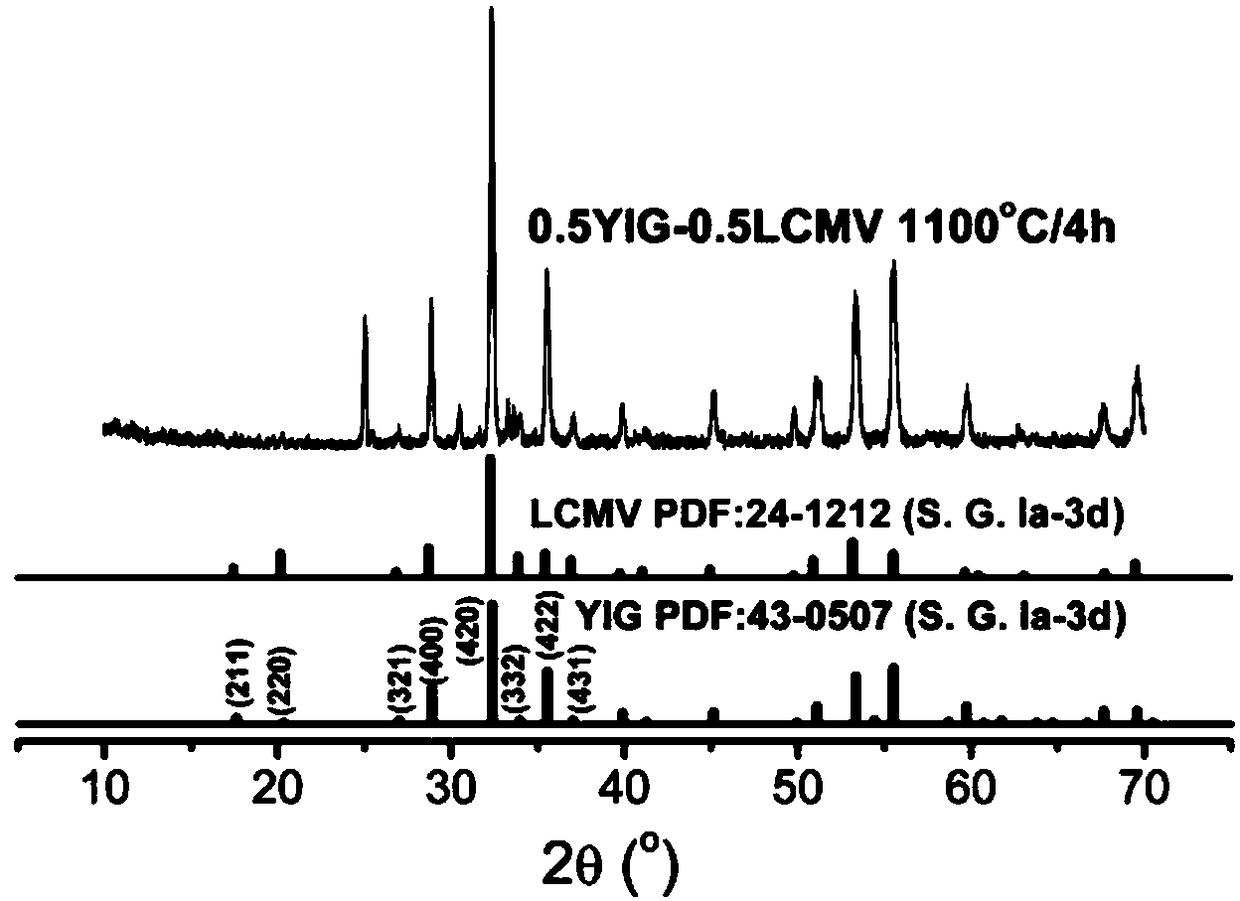

[0033] Prepare 0.5Y 3 Fe 5 o 12 -0.5Ca 3 LiMgV 3 o 12 Magnetodielectric functional dielectric ceramic material.

[0034] The analytically pure raw material Y 2 o 3 , Fe 2 o 3 , CaO, MgO, Li 2 CO 3 , V 2 o 5 , according to the formula 0.5Y 3 Fe 5 o 12 -0.5Ca 3 LiMgV 3 o 12 preparation. Mix the prepared chemical raw materials, then put them into a nylon tank, add anhydrous ethanol equal to the weight of the raw materials into the nylon tank, ball mill for 4 hours, fully mix and grind, take out after ball milling, and then quickly dry at 100-200°C Dry, pass through a 200-mesh sieve after drying, and then pre-press into a block; pre-burn the block to obtain a sample burnt block, the pre-burning condition is 1100 ° C for 4 hours; crush the sample burnt block and ball mill for 5-6 hours , fully mixed and ground, dried at 100-200°C after ball milling, added binder with 15% of the total mass of the powder after drying, the binder was 5% polyvinyl alcohol aqueous so...

Embodiment 2

[0039] Prepare 0.35Y 3 Fe 5 o 12 -0.65Ca 3 LiMgV 3 o 12 Magnetodielectric functional dielectric ceramic material.

[0040] The analytically pure raw material Y 2 o 3 , Fe 2 o 3 , CaO, MgO, Li 2 CO 3 , V 2 o 5 , according to the formula 0.35Y 3 Fe 5 o 12 -0.65Ca 3 LiMgV 3 o 12 preparation. Mix the prepared chemical raw materials, then put them into a nylon tank, add deionized water with 80% of the weight of the raw materials into the nylon tank, ball mill for 4 hours, fully mix and grind, take out after ball milling, and then quickly dry at 100-200°C Dry, pass through a 200-mesh sieve after drying, and then pre-press into a block; pre-burn the block to obtain a sample burnt block, the pre-burning condition is 800 ° C for 6 hours; crush the sample burnt block and ball mill for 5-6 hours , fully mixed and ground, dried at 100-200°C after ball milling, added binder with 15% of the total mass of the powder after drying, the binder was 5% polyvinyl alcohol aqueou...

Embodiment 3

[0043] Prepare 0.7Y 3 Fe 5 o 12 -0.3Ca 3 LiMgV 3 o 12 Magnetodielectric functional dielectric ceramic material.

[0044] The analytically pure raw material Y 2 o 3 , Fe 2 o 3 , CaO, MgO, Li 2 CO 3 , V 2 o 5 , according to the formula 0.7Y 3 Fe 5 o 12 -0.3Ca 3 LiMgV 3 o 12 preparation. Mix the prepared chemical raw materials, then put them into a nylon tank, add deionized water 120% of the weight of the raw materials into the nylon tank, ball mill for 4 hours, fully mix and grind, take out after ball milling, and then quickly Drying, passing through a 200-mesh sieve after drying, and then pre-pressing into a block; pre-calcining the block to obtain a sample burnt block, the pre-burning condition is 1000 ° C for 4 hours; crushing the sample burnt block and ball milling for 5-6 hours, fully mixed and ground, dried at 100-200°C after ball milling, added 12% binder of the total powder mass after drying, the binder was made of 5% polyvinyl alcohol aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com