Microwave-assisted method for compounding gangue and acetylene sludge into xonotlite fiber

A xonotlite and microwave-assisted technology, which is applied in chemical instruments and methods, silicates, transportation and packaging, etc., can solve the problems of large resource and environmental impact, high production energy consumption and cost, long hydrothermal reaction time, etc. problems, to achieve the effect of large aspect ratio, resource saving and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

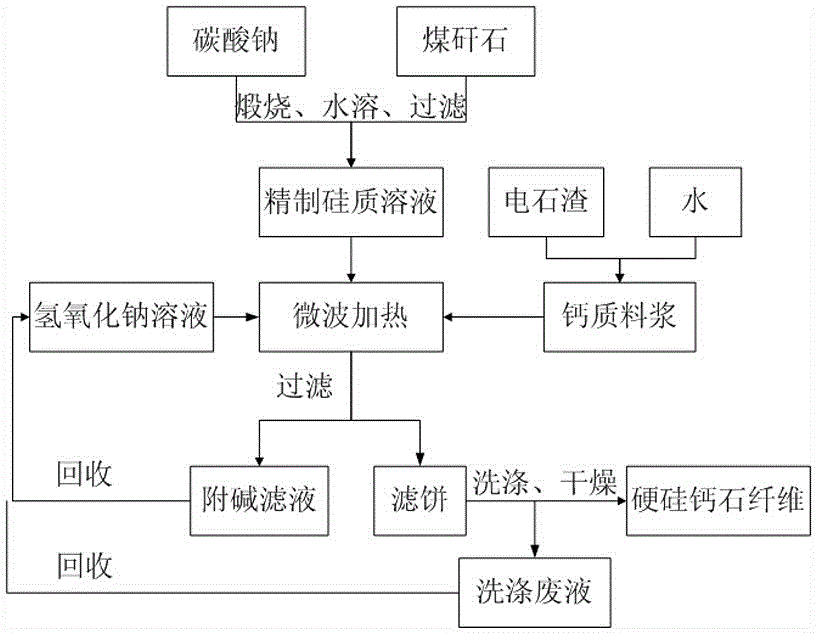

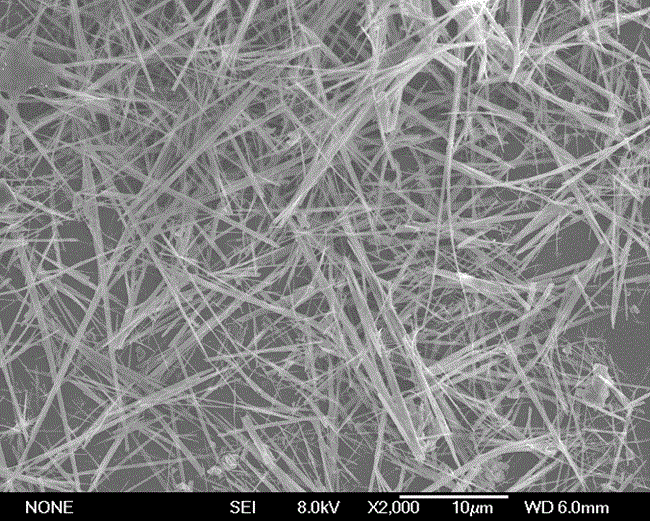

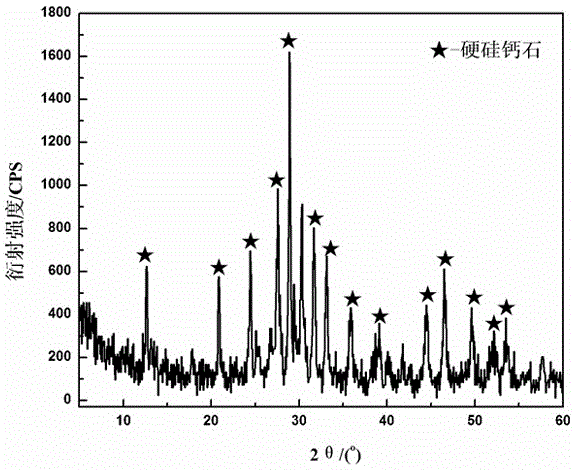

[0037] Microwave-assisted synthesis of xonotlite fibers from coal gangue and carbide slag, wherein the gangue contains 54.06% SiO 2 , 13.64% Al 2 o 3 , 2.67% CaO, 8.09% Fe 2 o 3 and 1.06% Na 2 O; Carbide slag contains 60% CaO, 4.34% SiO 2 , 2.24% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: mix calcium carbide slag with water to prepare calcium slurry with a mass concentration of 25%; mix coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2The molar ratio is 0.6:1 for batching, the calcination activation temperature is 600°C, and the calcination time is 1h. The activated product is mixed with hot water at a temperature of 85°C, and the water dissolution time is 1h. After filtering, a refined siliceous solution is obtained; The raw material slurry, the refined siliceous solution and the sodium hydroxide solution with a mass concentration of 1% are uniformly mixed according to the molar ratio of Ca:Si:Na of 1:1:1.4, heate...

Embodiment 2

[0040] Microwave-assisted synthesis of xonotlite fibers from coal gangue and carbide slag, wherein the gangue contains 56.86% SiO 2 , 12.74% Al 2 o 3 , 2.37% CaO, 7.68% Fe 2 o 3 and 1.36% Na 2 O; Carbide slag contains 65% CaO, 3.34% SiO 2 , 2.04% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: mix calcium carbide slag with water to prepare calcium slurry with a mass concentration of 20%; mix coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2 The molar ratio is 0.7:1 for batching, the calcination activation temperature is 500°C, and the calcination time is 2h. The activated product is mixed with hot water at a temperature of 95°C, and the water dissolution time is 1.5h. After filtering, a refined siliceous solution is obtained; Calcium slurry, refined siliceous solution and sodium hydroxide solution with a mass concentration of 2% are mixed evenly at a molar ratio of Ca:Si:Na of 0.95:1:1.7, heated to 170°C for 3 hours by ...

Embodiment 3

[0043] Microwave-assisted synthesis of xonotlite fibers from coal gangue and carbide slag, wherein the gangue contains 52.75% SiO 2 , 15.31% Al 2 o 3 , 2.16% CaO, 7.29% Fe 2 o 3 and 1.91% Na 2 O; Carbide slag contains 59.9% CaO, 3.34% SiO 2 , 2.24% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: mix calcium carbide slag with water to prepare calcium slurry with a mass concentration of 20%; mix coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2 The molar ratio is 0.65:1 for batching, the calcination activation temperature is 800°C, and the calcination time is 2h. The activated product is mixed with hot water at a temperature of 90°C, and the water dissolution time is 2h. After filtering, a refined siliceous solution is obtained; The raw material slurry, the refined siliceous solution and the sodium hydroxide solution with a mass concentration of 3% are uniformly mixed according to the molar ratio of Ca:Si:Na of 1:1:1.5, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com