Preparation method of magnesium oxide porous fiber

A technology of porous fiber and magnesium oxide, applied in the field of materials, can solve problems such as unprovable, impossible porous structure, unrecognizable porous structure, etc., and achieve the effect of single phase, simple raw material and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

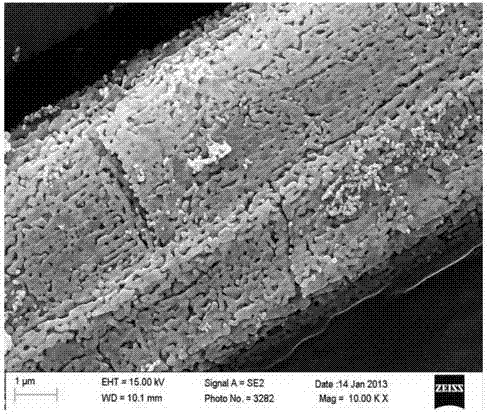

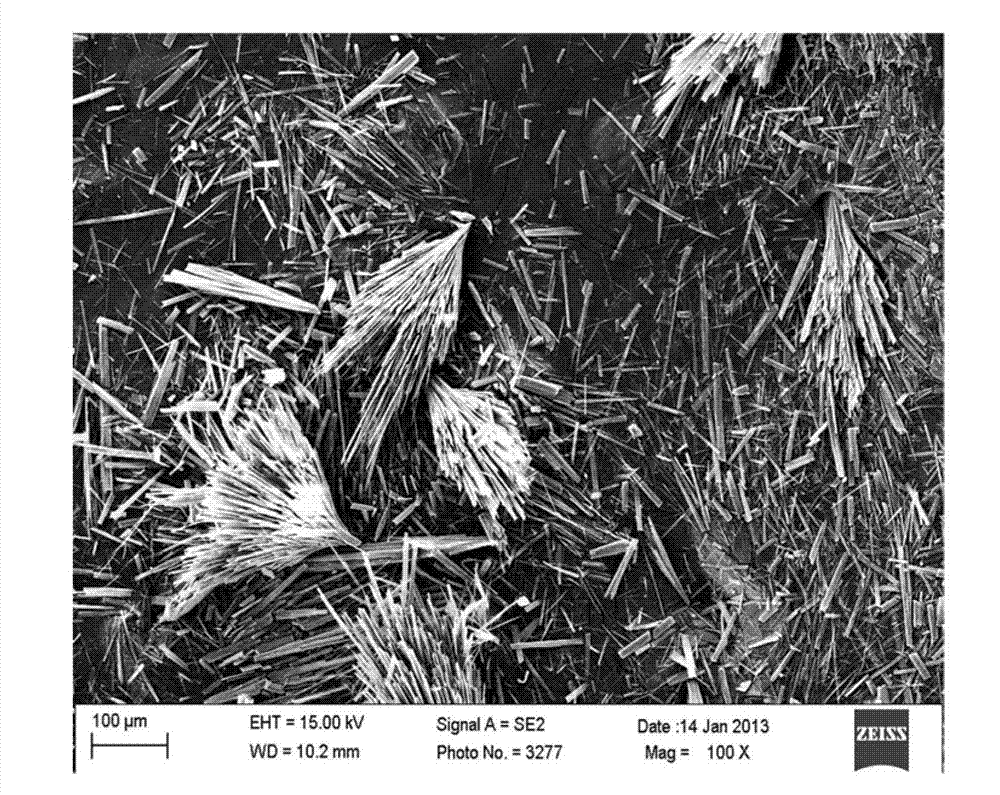

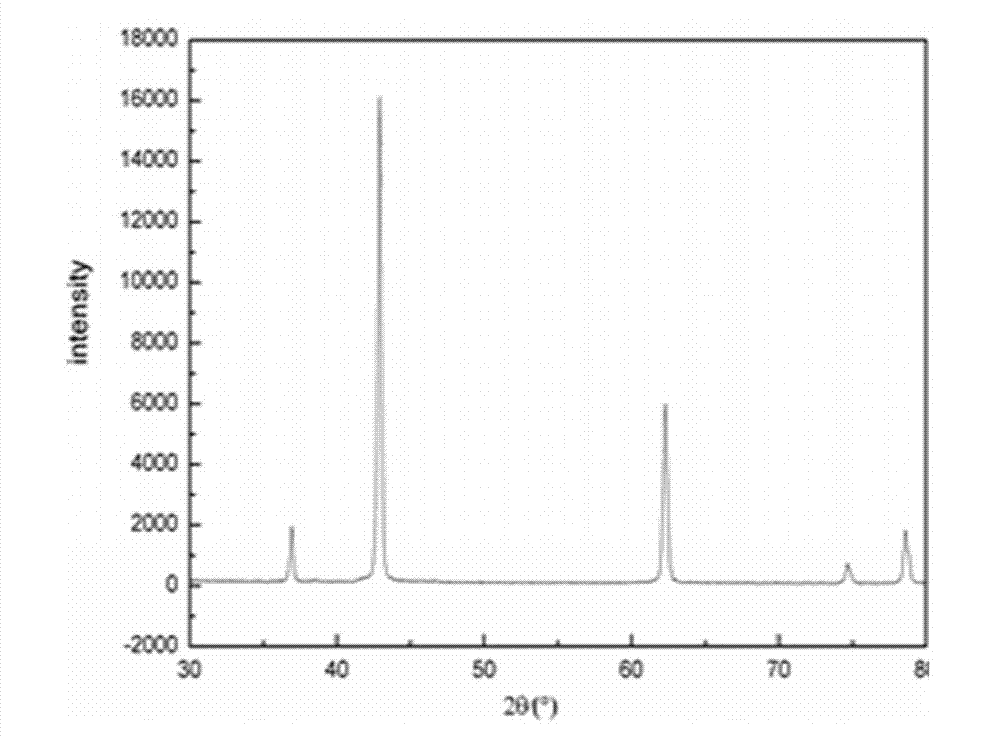

[0025] The preparation method of magnesium oxide porous fiber, comprises the steps:

[0026] 1) Dissolve a certain amount of polyethylene glycol with a molecular weight of 6000 in deionized water, add an appropriate amount of MgSO 4 ·7H 2 O, stirred at room temperature, then slowly added dropwise an appropriate amount of precipitant NaOH solution while stirring to obtain a mixed solution; wherein, in molar ratio, MgSO 4 : PEG: NaOH=2:0.01:1, MgSO in the mixed solution 4 ·7H 2 The concentration of O is 1.5-2mol / L;

[0027] 2) Transfer the mixed solution to an autoclave lined with polytetrafluoroethylene, and the filling degree is 80%. Put the sealed reaction kettle in a box-type resistance furnace for hydrothermal treatment at a temperature of 150-160°C for 10 ~12 hours, then naturally cooled to room temperature, aged for 12~15 hours, filtered, washed, and dried at 80~100°C to obtain the precursor basic magnesium sulfate fiber.

[0028] 3) Put the precursor basic magnesium...

Embodiment 2

[0030] The preparation method of magnesium oxide porous fiber, comprises the steps:

[0031] 1) Dissolve a certain amount of polyethylene glycol with a molecular weight of 6000 in deionized water, add an appropriate amount of MgSO 4 ·7H 2 O, stirred at room temperature, then slowly added dropwise an appropriate amount of precipitant NaOH solution while stirring to obtain a mixed solution; wherein, in molar ratio, MgSO 4 : PEG: NaOH=1.85:0.01:0.85, MgSO in the mixed solution 4 ·7H 2 The concentration of O is 1.8mol / L;

[0032] 2) Transfer the mixed solution to an autoclave lined with polytetrafluoroethylene, and the filling degree is 80%. Put the sealed reaction kettle in a box-type resistance furnace for hydrothermal treatment at a temperature of 150-160°C for 10 ~12 hours, then naturally cooled to room temperature, aged for 12~15 hours, filtered, washed, and dried at 80~100°C to obtain the precursor basic magnesium sulfate fiber.

[0033] 3) Put the precursor basic magne...

Embodiment 3

[0035] The preparation method of magnesium oxide porous fiber, comprises the steps:

[0036] 1) Dissolve a certain amount of polyethylene glycol with a molecular weight of 6000 in deionized water, add an appropriate amount of MgSO 4 ·7H 2 O, stirred at room temperature, then slowly added dropwise an appropriate amount of precipitant NaOH solution while stirring to obtain a mixed solution; wherein, in molar ratio, MgSO 4 : PEG: NaOH=2.05:0.02:1.05, MgSO in the mixed solution4 ·7H 2 The concentration of O is 1.5mol / L;

[0037] 2) Transfer the mixed solution to a polytetrafluoroethylene-lined autoclave with a filling degree of 80%, and place the sealed reaction kettle in a box-type resistance furnace for hydrothermal treatment at a temperature of 150-160°C for 10 ~12 hours, then naturally cooled to room temperature, aged for 12~15 hours, filtered, washed, and dried at 80~100°C to obtain the precursor basic magnesium sulfate fiber.

[0038] 3) Put the precursor basic magnesium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com