Preparation method of water-based nano magnetic fluid

A nano-magnetic fluid and water-based technology, which is applied in the manufacture of magnetic objects, magnetic liquids, inductors/transformers/magnets, etc., can solve the problems of unfavorable expansion of production, complicated process flow, and complicated operation process, and achieve easy expansion of production and raw materials. Cheap and easy to obtain, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

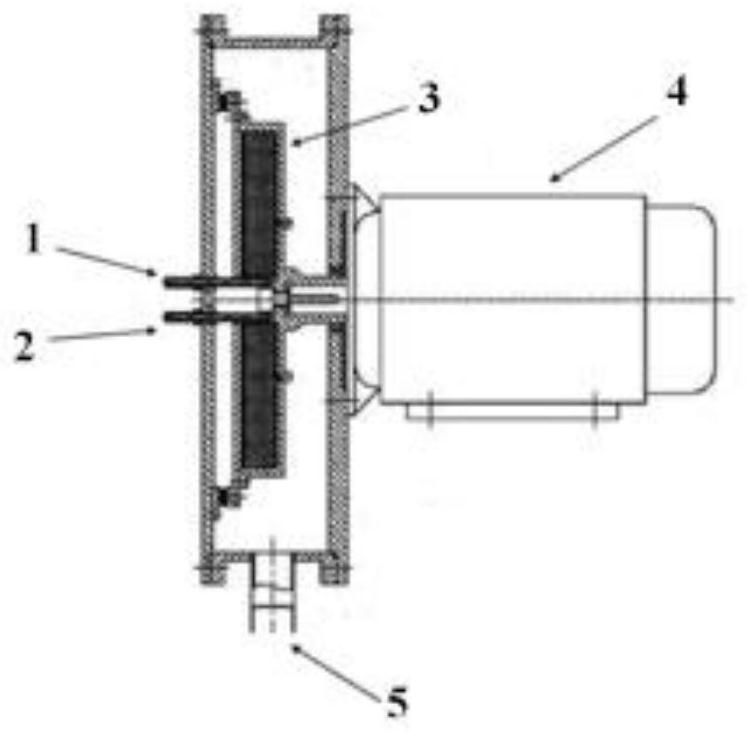

[0050] As an aspect of the present invention, a kind of preparation method of water-based nano-magnetic fluid of the present invention comprises the following steps:

[0051] S1, dissolving ferrous ferrous salt and ferric salt in an acidic solution to prepare a mixed solution of ferric salt, which is recorded as feed solution A;

[0052] S2, dissolve the alkali source in deionized water to prepare lye, which is recorded as feed liquid B;

[0053] S3, when feeding inert gas N 2 Under certain reaction conditions, the material liquid B is mixed with the material liquid A, heated in a water bath, stirred, and fully reacted;

[0054] S4, add tensio-active agent in the reaction solution after step S3 reaction, water bath heating, stirring, after the completion of the reaction, black precipitation nano iron ferric oxide particles are produced, continue to pass N 2 , and cooled to room temperature;

[0055] S5, collect black precipitate, use the mixed solution of organic solvent an...

Embodiment 1

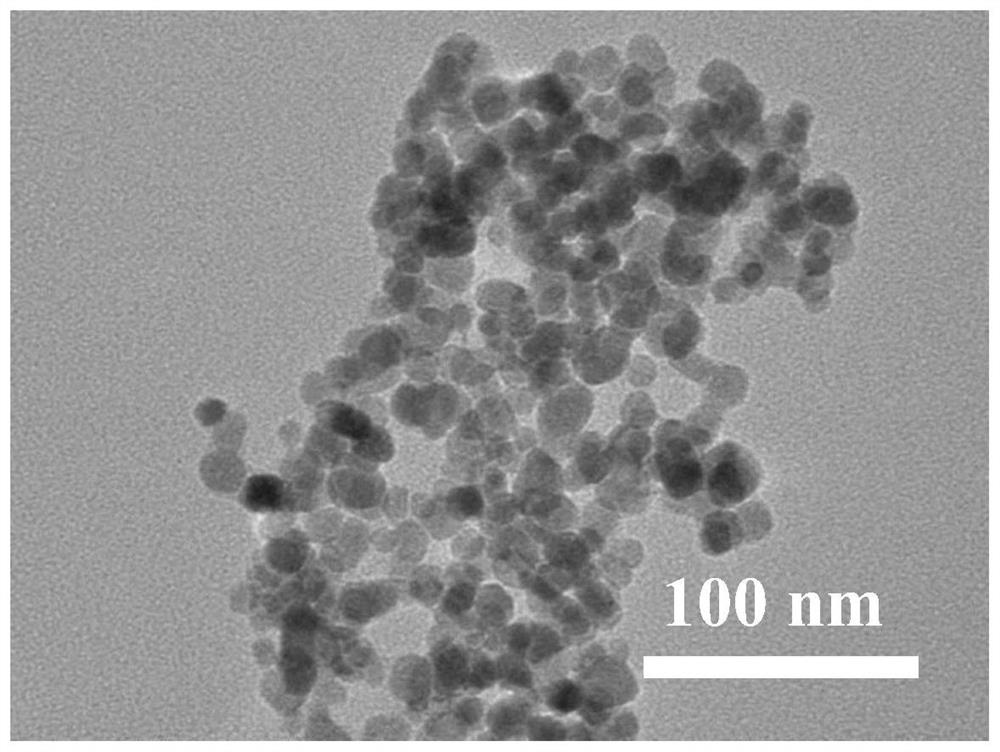

[0072] A preparation method of water-based nano-magnetic fluid, comprising the steps of:

[0073] 1) Prepare feed solution A: weigh 1.49g FeCl 2 4H 2 O and 4.06 g FeCl 3 ·6H 2 O was dissolved in 60 mL of dilute hydrochloric acid solution of 0.24 mol / L.

[0074] 2) Preparation of liquid B: 20mL 25wt.%NH 3 ·H 2 O was added to 30mL deionized water and diluted to 10wt.% for later use.

[0075] 3) Pour the material liquid A into a three-necked flask, and feed N 2 Fifteen minutes, remove the oxygen in the system, add feed liquid B to feed liquid A, and mechanically stir at a water bath heating temperature of 90°C.

[0076] 4) After mechanical stirring for 1 h, add 8 mL of sodium citrate solution with a concentration of 0.12 mol / L, and continue mechanical stirring for 1 h under heating in a water bath. After the reaction is complete, cool to room temperature.

[0077] 5) Collect the black precipitate and use a mixed solution of acetone and water for centrifugal washing, wherein...

Embodiment 2

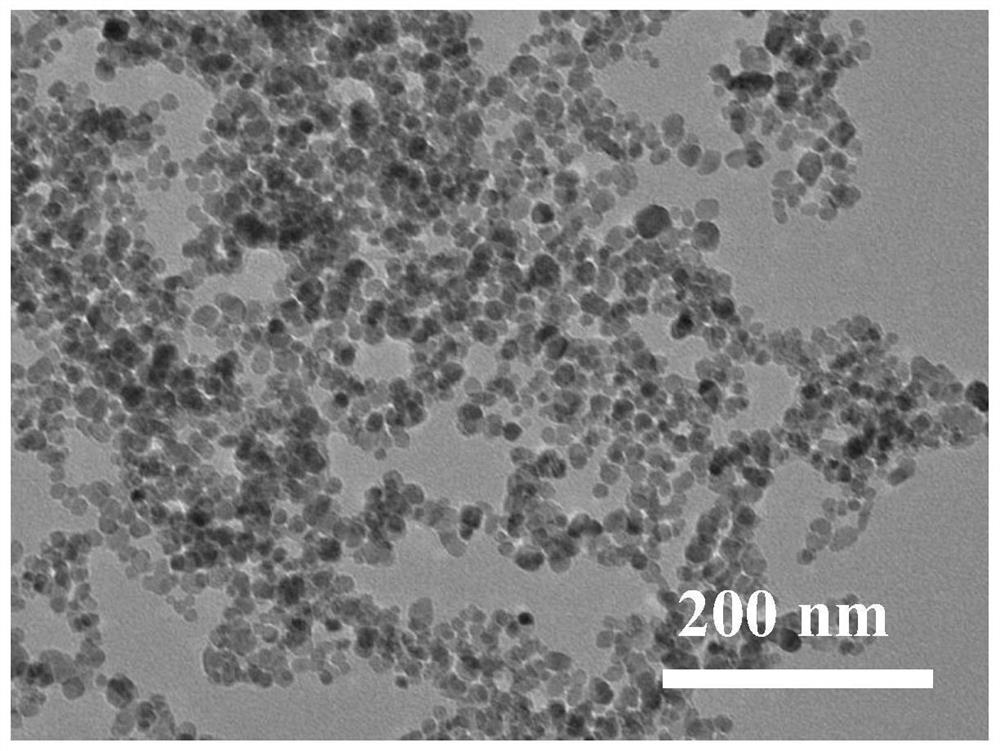

[0081] A preparation method of water-based nano-magnetic fluid, comprising the steps of:

[0082] 1) Prepare feed solution A: weigh 1.49g FeCl 2 4H 2 O and 4.06 g FeCl 3 ·6H 2 O was dissolved in 60 mL of dilute hydrochloric acid solution of 0.24 mol / L.

[0083] 2) Preparation of liquid B: 20mL 25wt.%NH 3 ·H 2 O was added to 30mL deionized water and diluted to 10wt.% for later use.

[0084] 3) Pour the material liquid A into a three-necked flask, and feed N 2 Fifteen minutes, remove the oxygen in the system, add feed liquid B to feed liquid A, and mechanically stir at a water bath heating temperature of 90°C.

[0085] 4) After mechanical stirring for 1 h, add 8 mL of sodium citrate solution with a concentration of 0.12 mol / L, and continue mechanical stirring for 1 h under heating in a water bath. After the reaction is complete, cool to room temperature.

[0086] 5) Collect the black precipitate and use a mixed solution of acetone and water for centrifugal washing, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com