Process for preparing carbon coated graphite microparticles

A technology of graphite micropowder and carbon coating, which is applied in the treatment of dyed polymer organic compounds and fibrous fillers. The effect of long discharge platform and low charge and discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

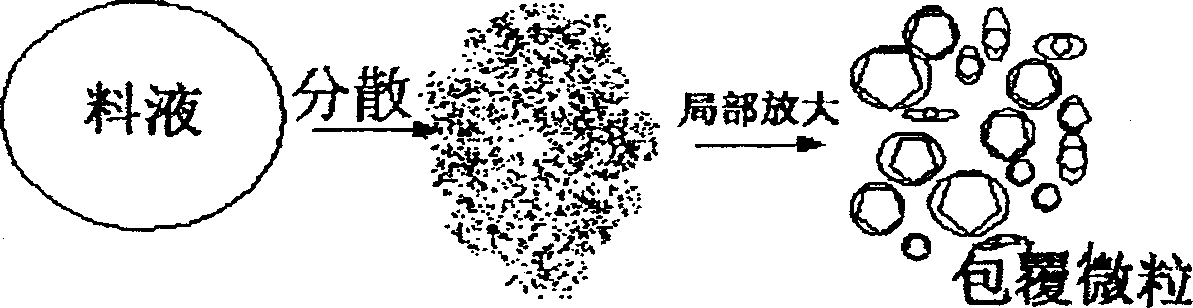

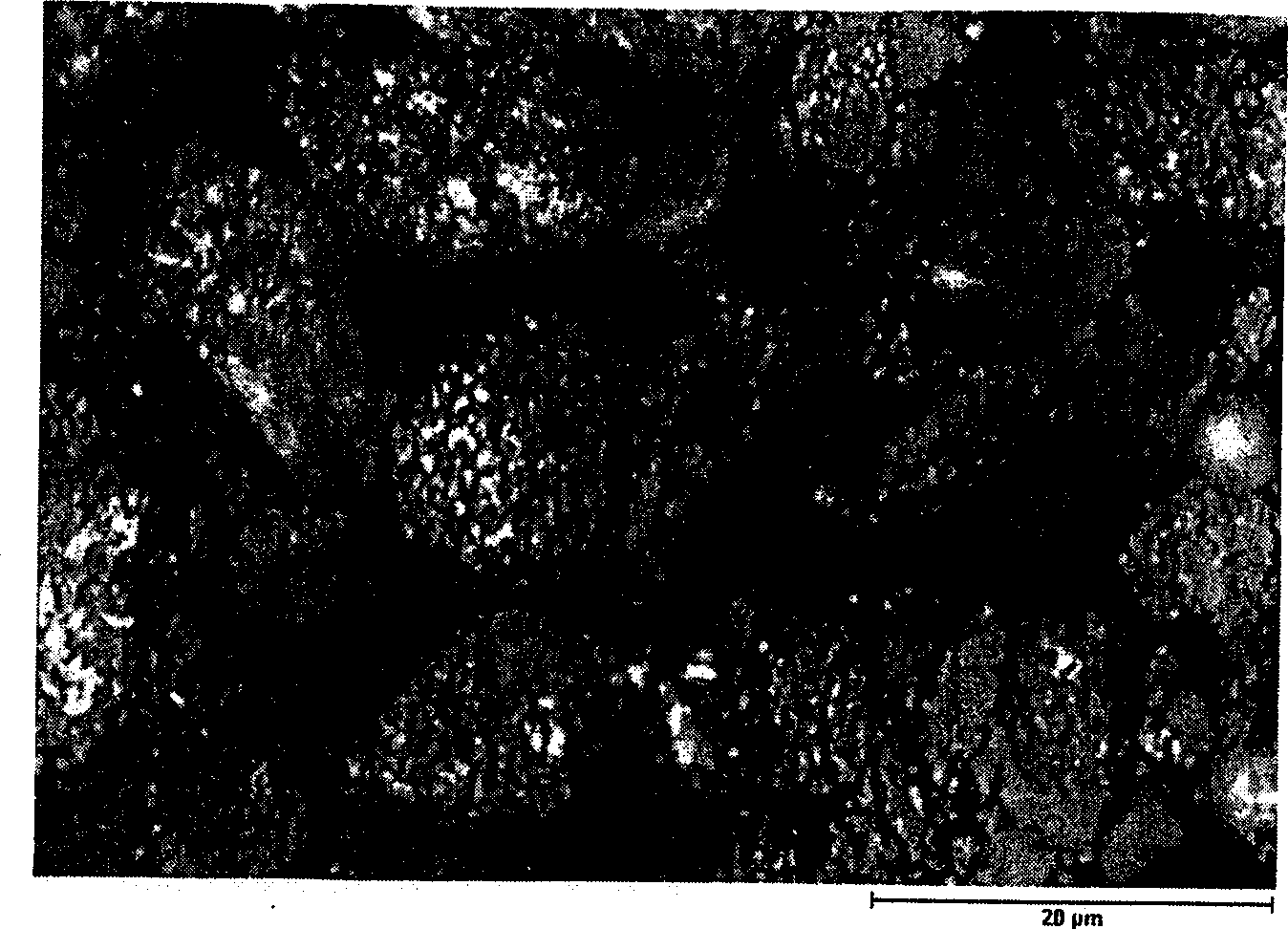

[0011] The present invention is a preparation method of carbon-coated graphite micropowder used as a lithium-ion battery negative electrode material, figure 1 Shown is a schematic diagram of the preparation of carbon-coated graphite powder. Carbon-coated graphite powder is prepared by spray granulation. Firstly, the graphite powder, resin and ethanol used as the carbon coating layer are mixed at a volume ratio of 1:1:1 to form a suspension, and the prepared suspension is sprayed at a high speed. In this process, due to the effect of surface energy, the fluid resin liquid will flow and shrink, and the graphite powder will be coated to form coated graphite, and then the composite powder obtained by spray granulation , dried in hot air, and then carbonized at 700-1200°C to obtain carbon-coated graphite powder (such as figure 2 shown). The resin used for the cladding layer is phenolic resin, epoxy resin, or furfural resin. Above-mentioned graphite micropowder is natural microc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com