Lithium ion battery graphite anode material and preparation method thereof

A lithium-ion battery, graphite negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor charging and discharging performance, large particle size, etc., and achieve good stability in use, small particle size, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

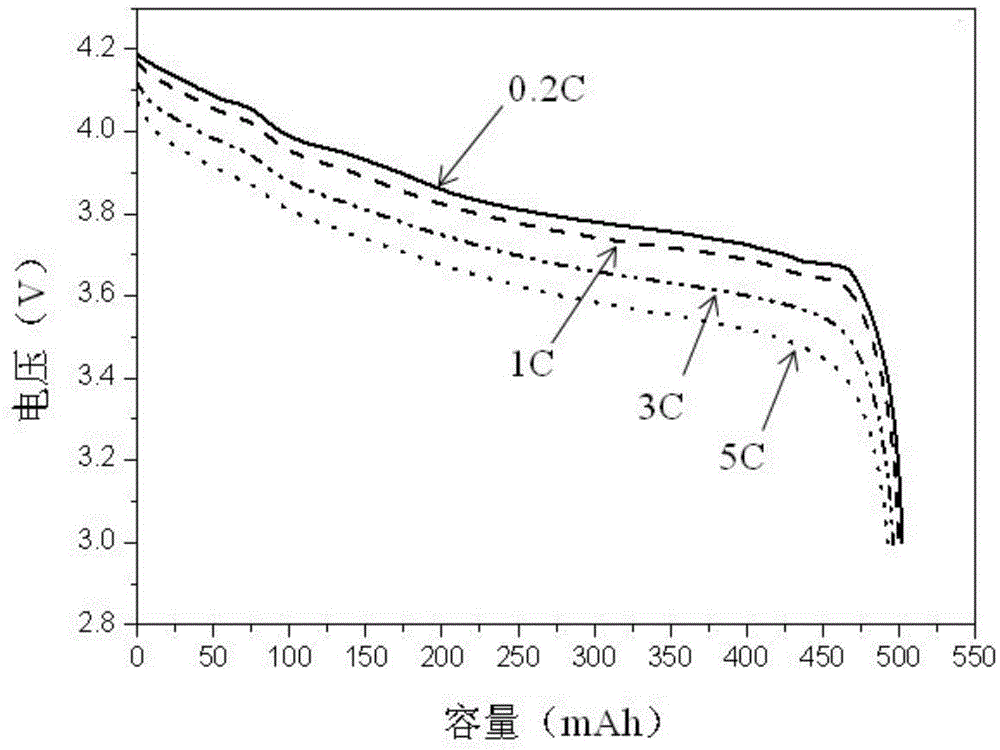

Examples

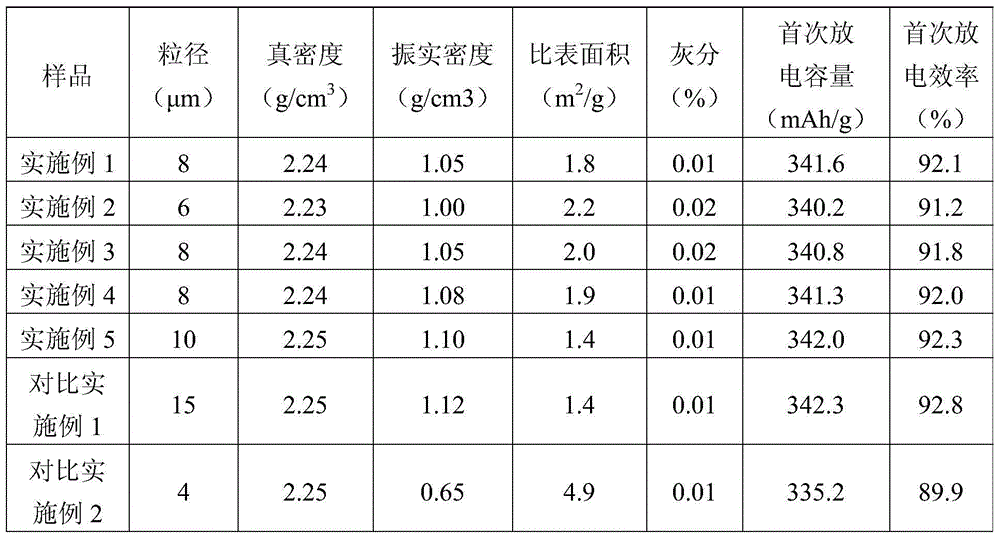

Embodiment 1

[0027] Preparation of graphite anode material for lithium ion battery: The raw material is petroleum green coke A (volatile content 14wt%), which is crushed until the particle size of the powder is 5 μm, reacted in a high-temperature reactor at a final temperature of 550°C, and carbonized at 1100°C Treat for 12 hours, then graphitize at 2800°C for 20 days, and finally classify and control the particle size at 8 μm, with a yield of 72%.

Embodiment 2

[0029] Preparation of graphite anode material for lithium ion battery: The raw material is petroleum green coke A (volatile content 14wt%), which is pulverized until the particle size of the powder is 3 μm, reacted in a high-temperature reactor at a final temperature of 550°C, and carbonized at 1100°C Treat for 12 hours, then graphitize at 2800°C for 20 days, and finally classify and control the particle size to 6 μm, with a yield of 69%.

Embodiment 3

[0031] Preparation of graphite anode material for lithium ion battery: The raw material is petroleum green coke A (14wt% volatile matter), which is crushed until the particle size of the powder is 5 μm, reacted in a high-temperature reactor at a final temperature of 500°C, and carbonized at 1100°C Treat for 12 hours, then graphitize at 2800°C for 20 days, and finally classify and control the particle size to 8 μm, with a yield of 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com