Metal Precursor Solutions For Chemical Vapor Deposition

a technology of metal precursors and vapor deposition, which is applied in the direction of liquid/solution decomposition chemical coating, solid/suspension decomposition chemical coating, coating, etc., can solve the problems of stoichiometry errors, affecting the stoichiometry of deposited films, etc., and achieves the effect of convenient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of 1.0M solution of titanium isopropoxide in N-methyl-2-pyrrolidinone

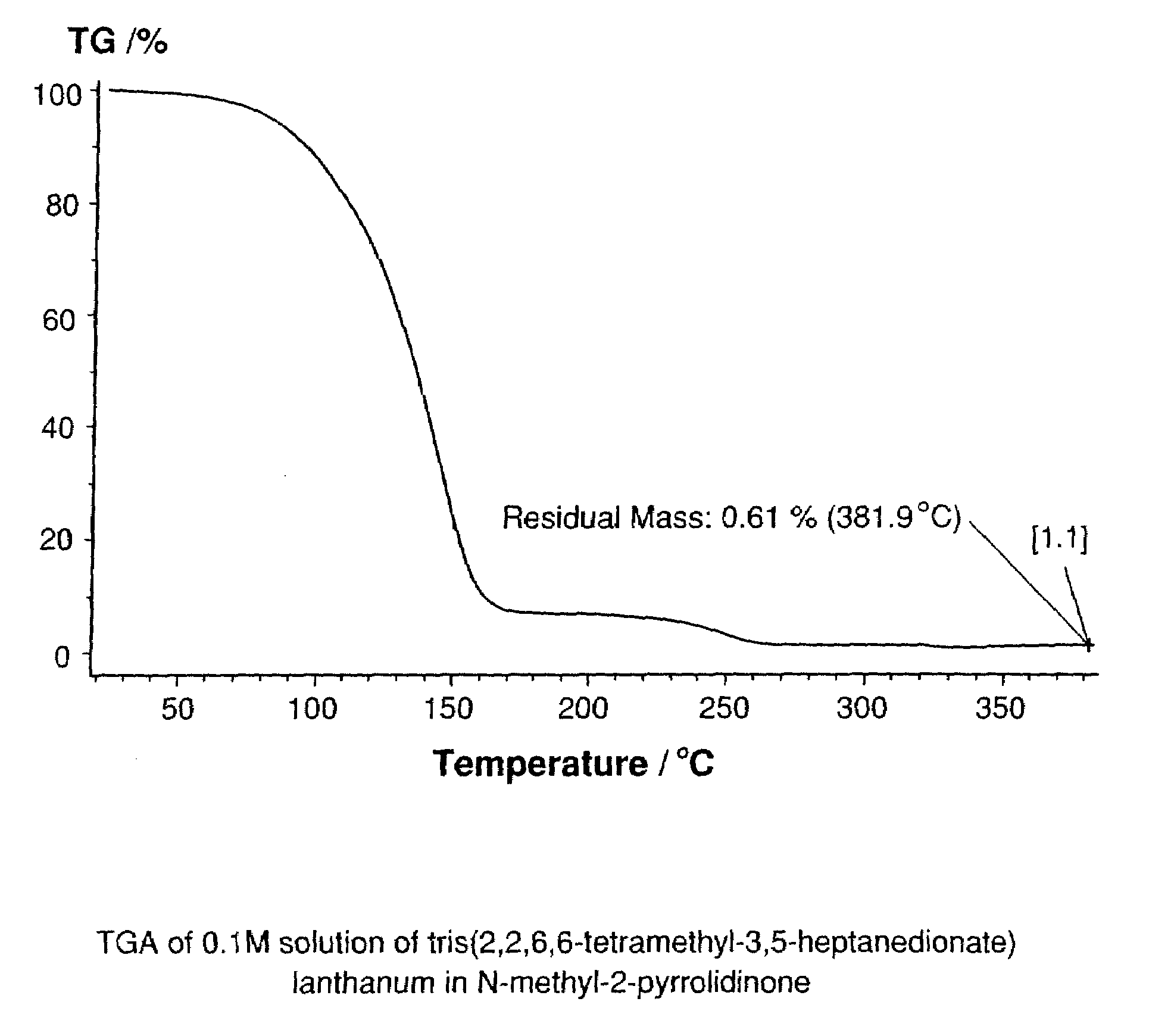

[0050]To a 2 mL vial, a faint yellow orange solution of titanium isopropoxide (0.10 g, 0.35 mmol) and 0.35 mL N-methyl-2-pyrrolidinone (NMP) was prepared. The solution was kept at room temperature over night and did not show any visible change. FIG. 1 is a TGA of the 1.M solution of titanium isopropoxide in N-methyl-2-pyrrolidinone, suggesting a smooth vaporization process in the temperature range of 20 to 400° C. This vaporization behavior suggests the solution can be employed either via bubbling or direct liquid injection for chemical vapor deposition or atomic vapor deposition.

example 2

Preparation of 0.1M solution of tris(2,2,6,6-tetramethyl-3,5-heptanedionate)lanthanum in N-methyl-2-pyrrolidinone

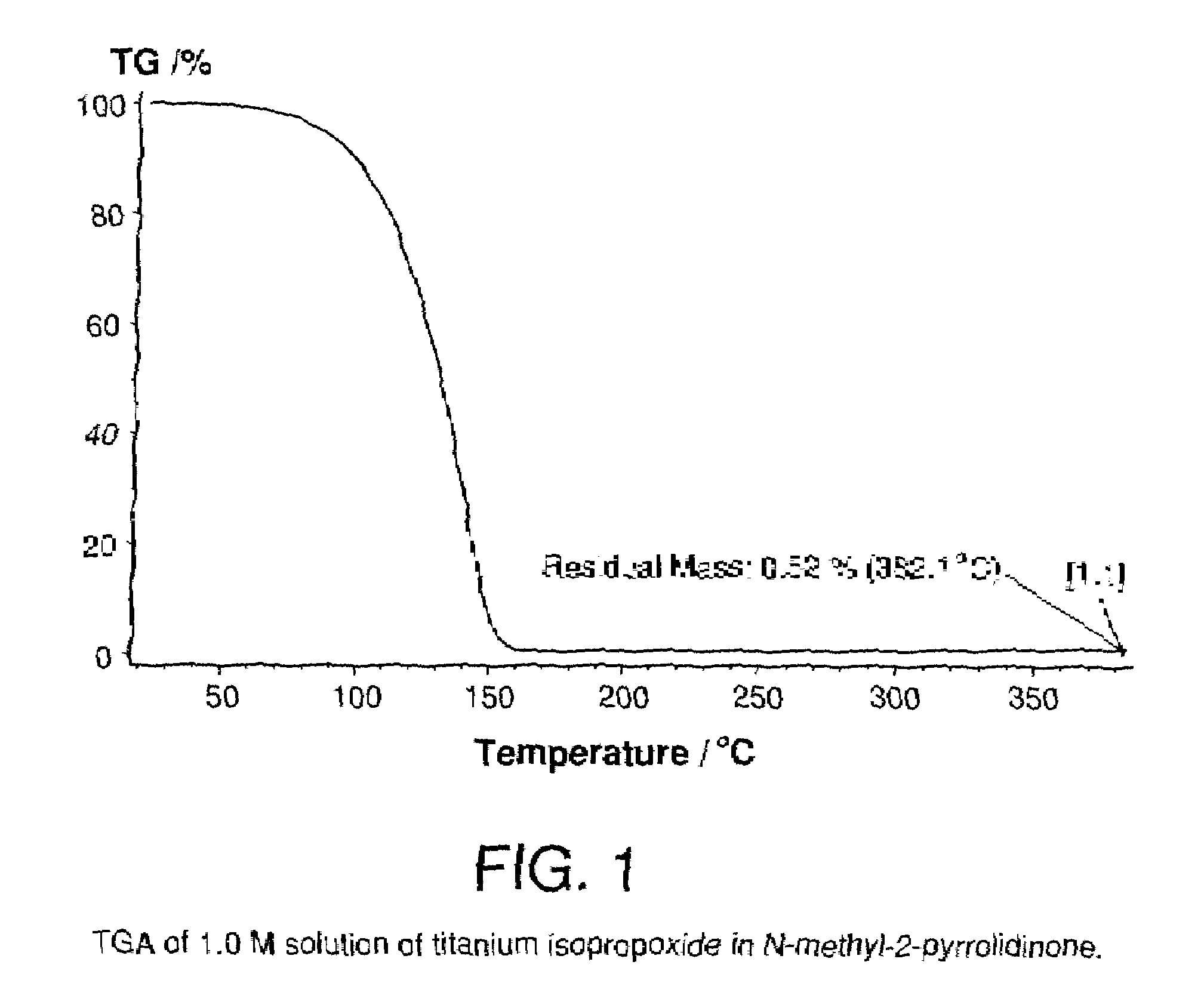

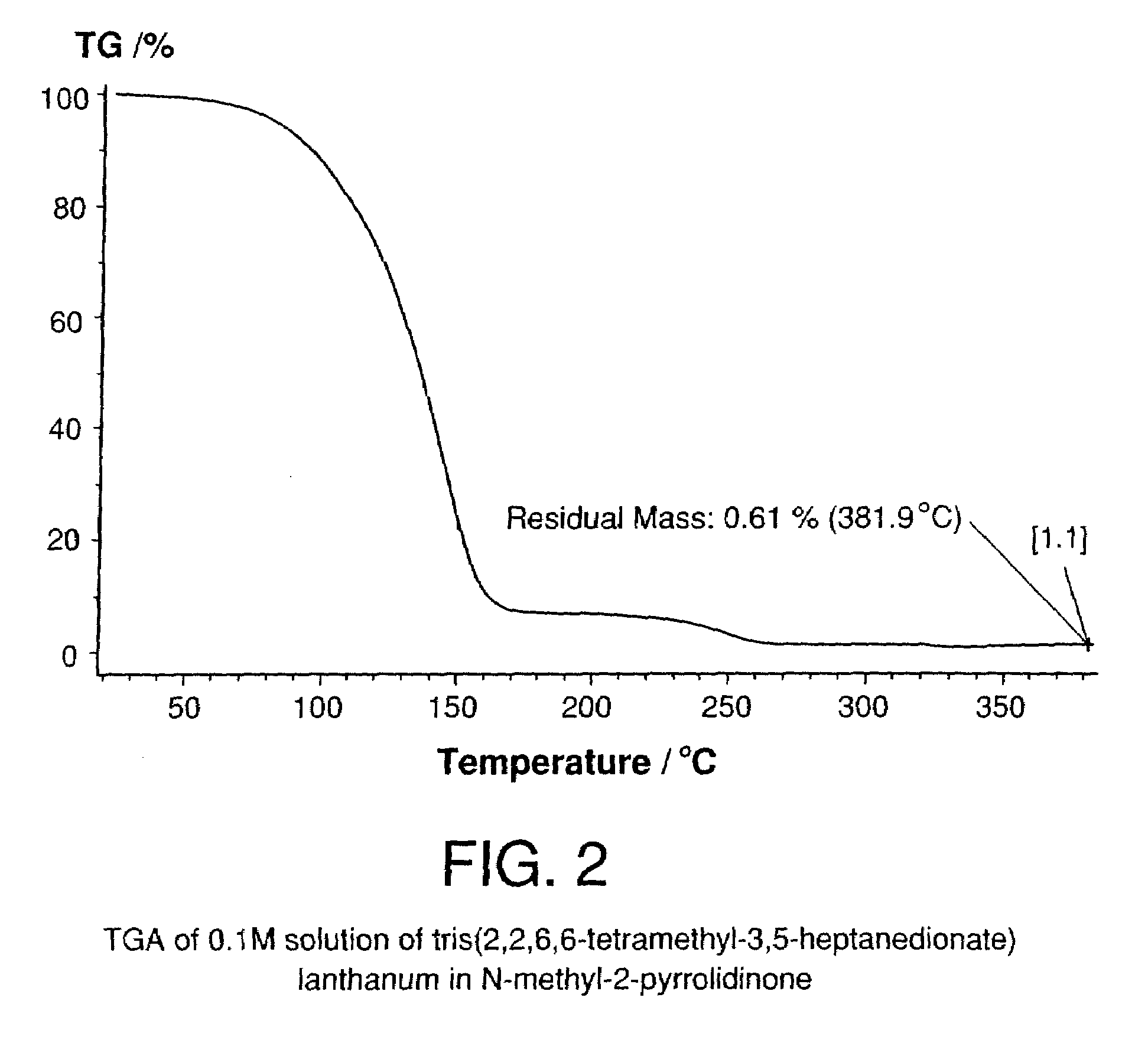

[0051]To a 2 mL vial, a clear solution of La(thd)3) (0.05 g, 0.07 mmol) and 0.78 mL NMP was prepared. FIG. 2 is a TGA of 0.1M solution of tris(2,2,6,6-tetramethyl-3,5-heptanedionate)lanthanum in N-methyl-2-pyrrolidinone, indicating there are two vaporization processes, the first is mainly for NMP and the second tris(2,2,6,6-tetramethyl-3,5-heptanedionate)lanthanum. This vaporization behavior suggests the solution can be only employed via direct liquid injection for chemical vapor deposition or atomic vapor deposition.

example 3

Preparation of solutions of tetrakis(ethylmethylamino)zirconium in N-methyl-2-pyrrolidinone

[0052]Three solutions of tetrakis(ethylmethylamino)zirconium (TEMAZ) in NMP were prepared according to Table 1. All are clear yellow solutions.

TABLE 1TEMAZSample(g)NMP (g)A0.21.8B0.240.35C0.20.2

[0053]FIG. 3 shows TGA diagrams of the solutions, suggesting that direct liquid injection with a lower concentration is preferred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| valence | aaaaa | aaaaa |

| chemical | aaaaa | aaaaa |

| physical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com