Method for producing glycol product by separating synthetic gas

A technology of ethylene glycol and synthesis gas, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem that the synthesis gas to ethylene glycol product does not involve separation process reports and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

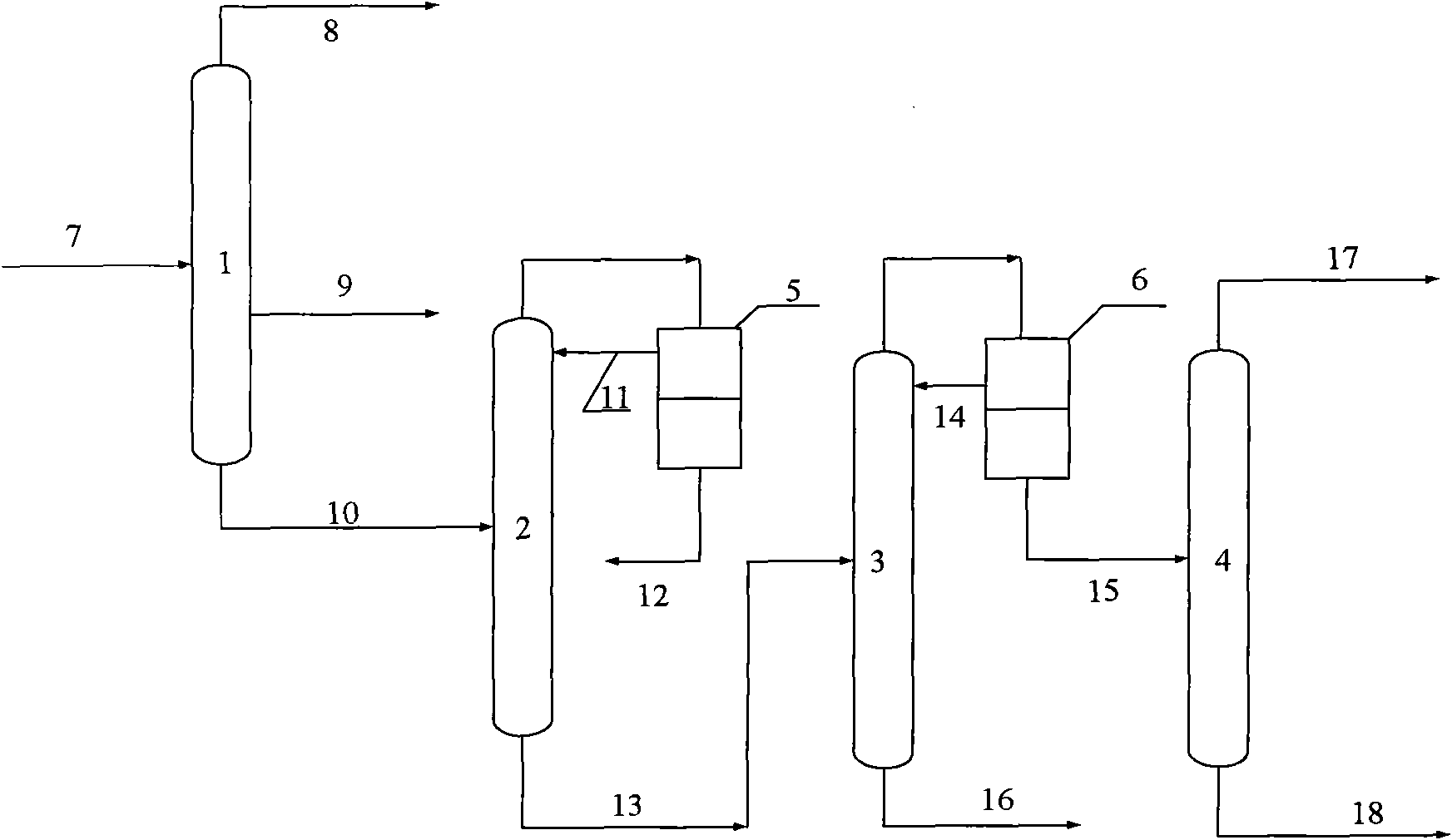

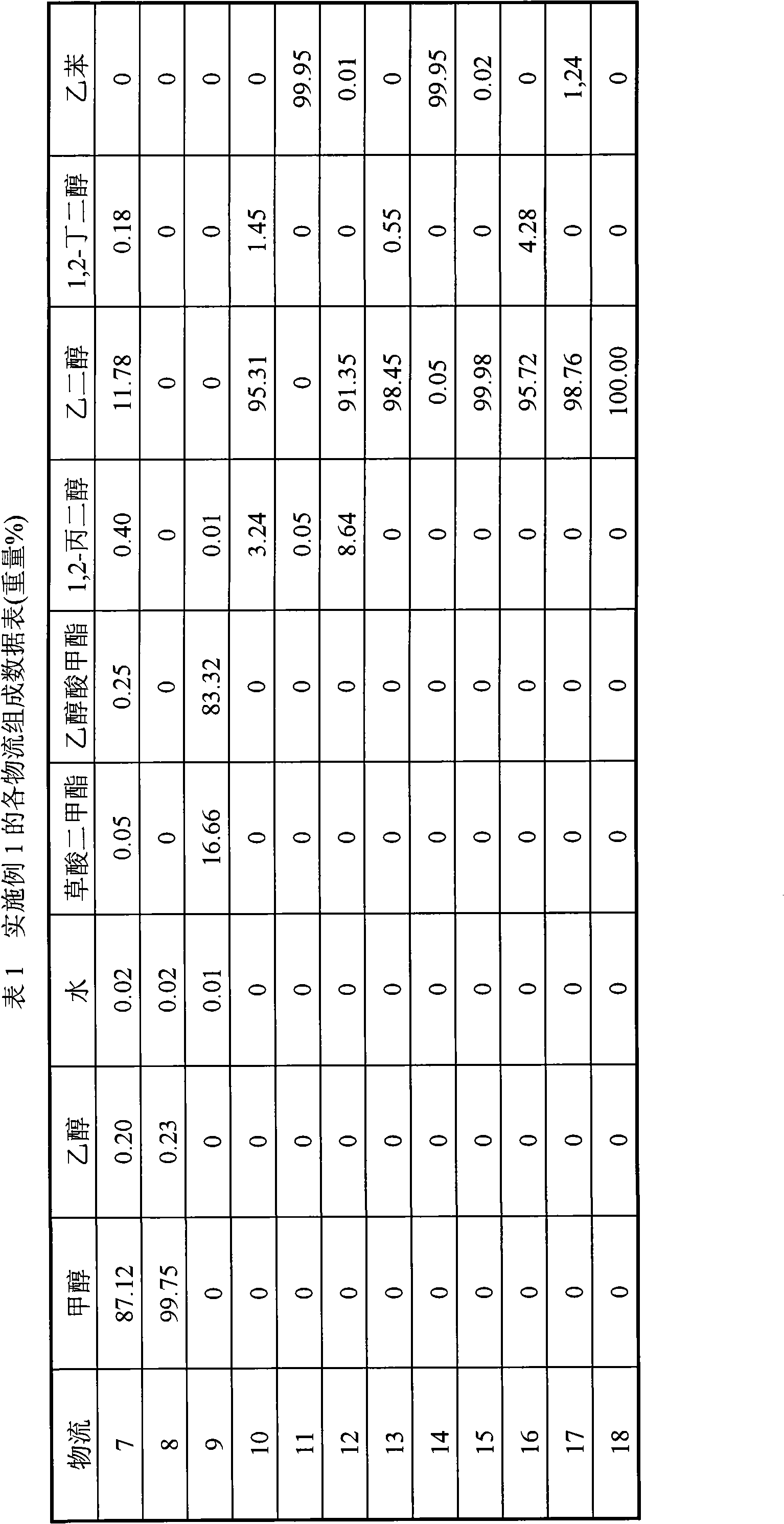

[0014] according to figure 1 In the process shown, the product of synthesis gas to ethylene glycol is used as raw material 7, and raw material 7 enters the 40th plate of the fraction cutting tower 1 with a theoretical plate number of 60, the operating pressure is 20KPa, the reflux ratio is 2, and the top extraction control No methyl glycolate, no 1,2-propanediol in the side stream control, no dimethyl oxalate in the bottom stream control, a methanol-rich mixture 8 is obtained at the top of the tower, and glycolic acid is extracted from the 45th plate in the side stream The mixture 9 of methyl ester and dimethyl oxalate, the tower still obtains the heavy component 10 that is rich in ethylene glycol; The theoretical plate and the top enter, the operating pressure is 10KPa, the mass ratio of the entrainer to the feed is 0.1, and the output stream of the tower kettle is controlled to contain no 1,2-propanediol. After the tower top steam is condensed, it enters the phase separator ...

Embodiment 2

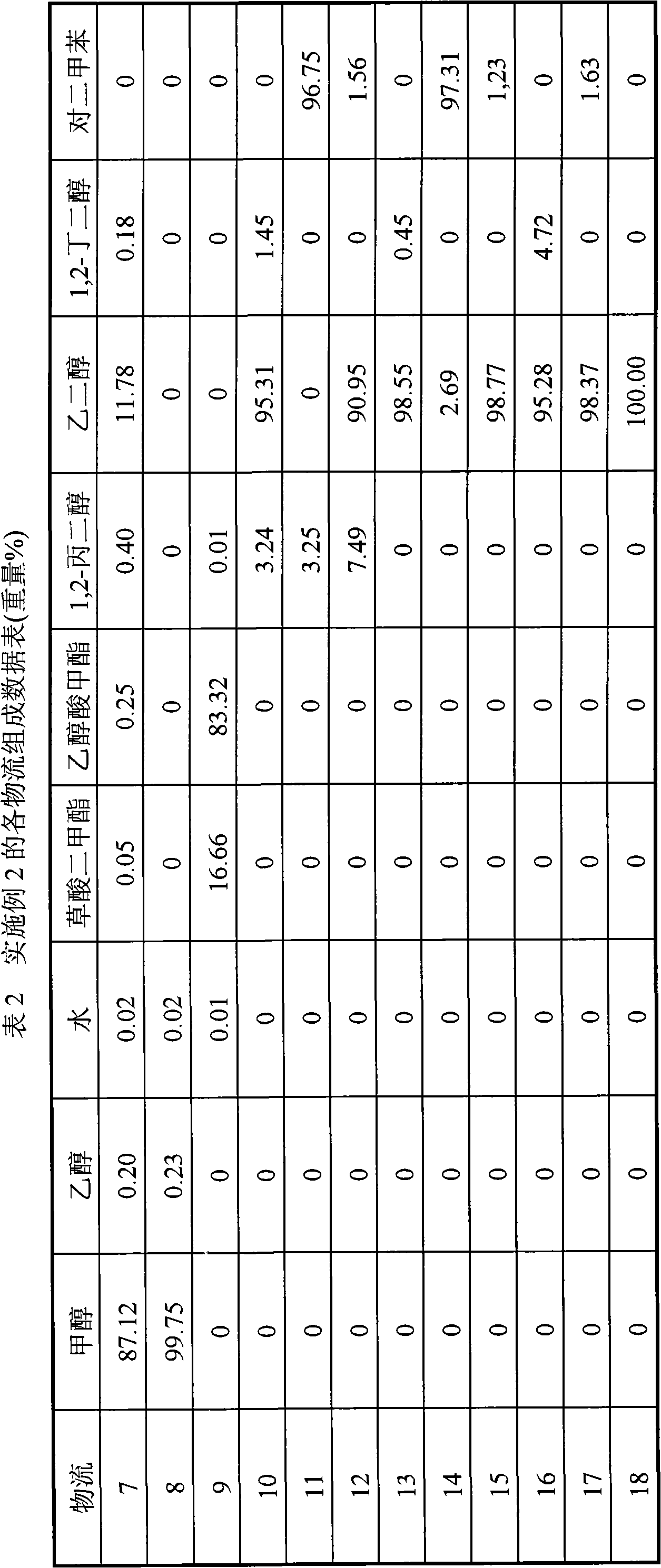

[0016] according to figure 1In the process shown, the product of synthesis gas to ethylene glycol is used as raw material 7, and raw material 7 enters the 50th plate of the fraction cutting tower 1 with a theoretical plate number of 80, the operating pressure is 5KPa, the reflux ratio is 0.5, and the top extraction control No methyl glycolate, no 1,2-propanediol in the side stream control, no dimethyl oxalate in the bottom stream control, a methanol-rich mixture 8 is obtained at the top of the tower, and glycolic acid is extracted from the 45th plate in the side stream The mixture 9 of methyl ester and dimethyl oxalate, the tower still obtains the heavy component 10 that is rich in ethylene glycol; The theoretical plate and the top enter, the operating pressure is 5KPa, the mass ratio of the entrainer to the feed is 0.05, and the output stream of the tower kettle is controlled to contain no 1,2-propanediol. After the tower top steam is condensed, it enters the phase separator ...

Embodiment 3

[0018] according to figure 1 In the process shown, the product of synthesis gas to ethylene glycol is used as raw material 7, and raw material 7 enters the 12th plate of the fraction cutting tower 1 with a theoretical plate number of 20, the operating pressure is 50KPa, the reflux ratio is 5, and the top extraction control No methyl glycolate, no 1,2-propanediol in the side stream control, no dimethyl oxalate in the bottom stream control, a methanol-rich mixture 8 is obtained at the top of the tower, and glycolic acid is extracted from the 15th plate in the side stream The mixture 9 of methyl ester and dimethyl oxalate, the tower still obtains the heavy component 10 that is rich in ethylene glycol; The theoretical plate and the top enter, the operating pressure is 50KPa, the mass ratio of the entrainer to the feed is 0.5, and the output stream of the tower kettle is controlled to contain no 1,2-propylene glycol. After the tower top steam is condensed, it enters the phase separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com