Core-shell composite micron/nano fiber and preparation method thereof

A technology of composite fiber and core-shell structure, applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve limitations and other problems, achieve high encapsulation rate, stable structure effect, and avoid denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The polystyrene microspheres prepared in aqueous phase by emulsion method, its solid content is 10%, and the average diameter of microspheres is 500 nanometers.

[0035] 2. Add 0.6 g of polyvinyl alcohol to 10 g of the emulsion to dissolve the polyvinyl alcohol to form a two-phase polymer spinning solution.

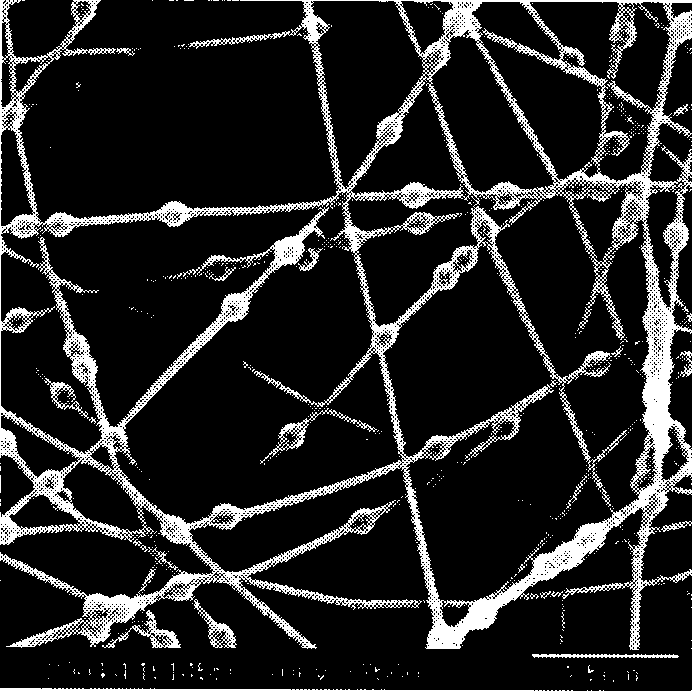

[0036] 3. Add the prepared spinning solution into the liquid storage tank of the electrospinning device (such as Figure 4 Shown), using No. 9 flat spinneret, the flow rate of the spinning solution is 0.1ml / h, and the applied voltage is 5kV for electrospinning. A polyvinyl alcohol nanofiber film embedded with polystyrene microspheres was obtained on a receiver at 15 cm below the spinneret. The fibers have an average diameter of about 400 microns. Its microstructure is as figure 1 shown.

Embodiment 2

[0038] 1. The calcium alginate microsphere emulsion that is loaded with transforming growth factor (TGF-β) prepared in chloroform, its solid content is 5%, microsphere average diameter 5 microns.

[0039] 2. Add 0.1 g of polylactic acid to 10 g of this emulsion, stir to fully dissolve PLLA, and prepare a polymer spinning solution with two-phase components.

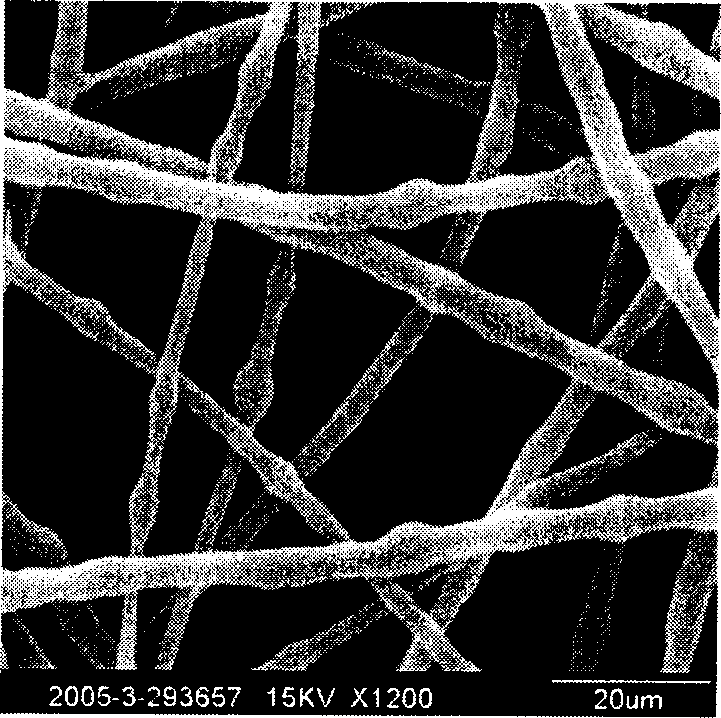

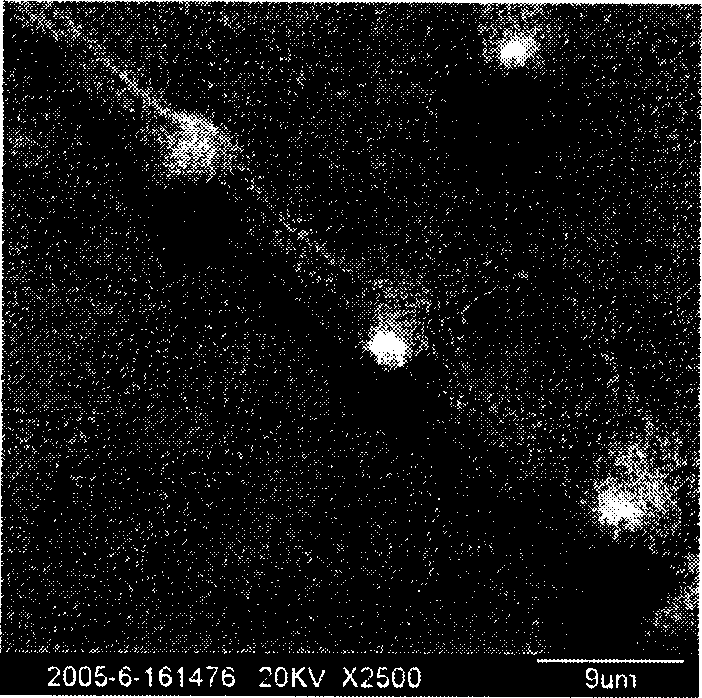

[0040] 3. Add the prepared spinning solution into the liquid storage tank of the electrospinning device (such as Figure 4 Shown), using the No. 9 flat spinneret, the flow rate of the spinning solution is 0.8ml / h, and the applied voltage is 40kV for electrospinning. Polylactic acid composite fibers embedded with calcium alginate microspheres were obtained on a receiver 15 cm below the spinneret. The average fiber diameter is about 4.5 microns, and its microstructure is as follows figure 2 and image 3 shown.

Embodiment 3

[0042] 1. the calcium alginate microsphere emulsion that is loaded with nerve growth factor (NGF) prepared in chloroform, solid content 5%, microsphere average diameter 15 microns

[0043] 2. Mix the emulsion with polypropylene carbonate and tacrolimus (FK506) in a mass ratio of 100:43:1, stir to dissolve the solids fully, and prepare a polymer spinning solution with two-phase components.

[0044] 3. Add the prepared spinning solution into the liquid storage tank of the electrospinning device (such as Figure 4 Shown), using No. 9 flat spinneret, the flow rate of the spinning solution is 4ml / h, and the applied voltage is 5kV for electrospinning. Polypropylene carbonate composite fibers embedded with calcium alginate microspheres were obtained on a receiver at 15 cm below the spinneret. The fibers are about 10 microns in diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com