Method for preparing B4C-Al composite material

A composite material, b4c-al technology, applied in the field of preparing B4C-Al composite materials, can solve problems such as poor mechanical properties, achieve the effect of enhancing mechanical properties, reducing the degree of welding, and inhibiting excessive welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

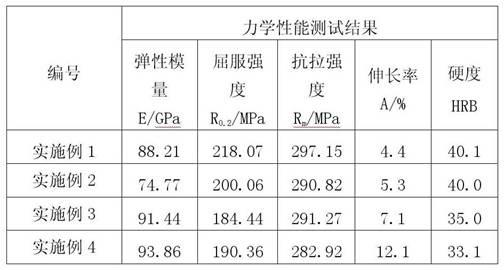

Examples

Embodiment 1

[0025]Weigh the boron carbide powder and aluminum alloy powder of type 6061 according to the mass ratio of 15%:85%, and put them into a high-energy ball mill for cyclic variable speed ball milling. The speed is alternately changed between 300rpm and 600rpm, and each speed is ball milled for 300sec. (Denoted by 300rpm / 300sec~600rpm / 300sec, the same below), continuous ball milling for 3 hours, adding 2% stearic acid as a process control agent, the ratio of ball to material is 10:1, and the ball milling process is protected by argon. After ball milling, it is formed by unidirectional pressing, with a pressure of 30MPa, and the pressure is kept for 3 minutes; the compact is placed in a vacuum sintering furnace, and sintered at 550°C for 4h; the sintered sample is extruded at 430°C; Multiple times of hot rolling, each time the deformation is controlled within 5%, and finally a composite plate with a thickness of about 3mm is obtained.

Embodiment 2

[0027] Select the ball-to-material ratio as 15:1, add 0.5% zinc stearate as a process control agent, and ball mill for 8 hours; select the sintering temperature to be 600°C, the extrusion temperature to be 520°C, and the hot rolling temperature to be 430°C, and the rest of the conditions are the same as in the examples 1 to proceed.

Embodiment 3

[0029] The selected sintering temperature is 520°C, the extrusion temperature is 470°C, the hot rolling temperature is 450°C, and the rest of the conditions are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com