Method for manufacturing polyacrylonitrile-based carbon fiber with enganced carbon nano-tube

A technology of polyacrylonitrile-based carbon fibers and carbon nanotubes is applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., to achieve the effects of improving breaking strength, simple preparation process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

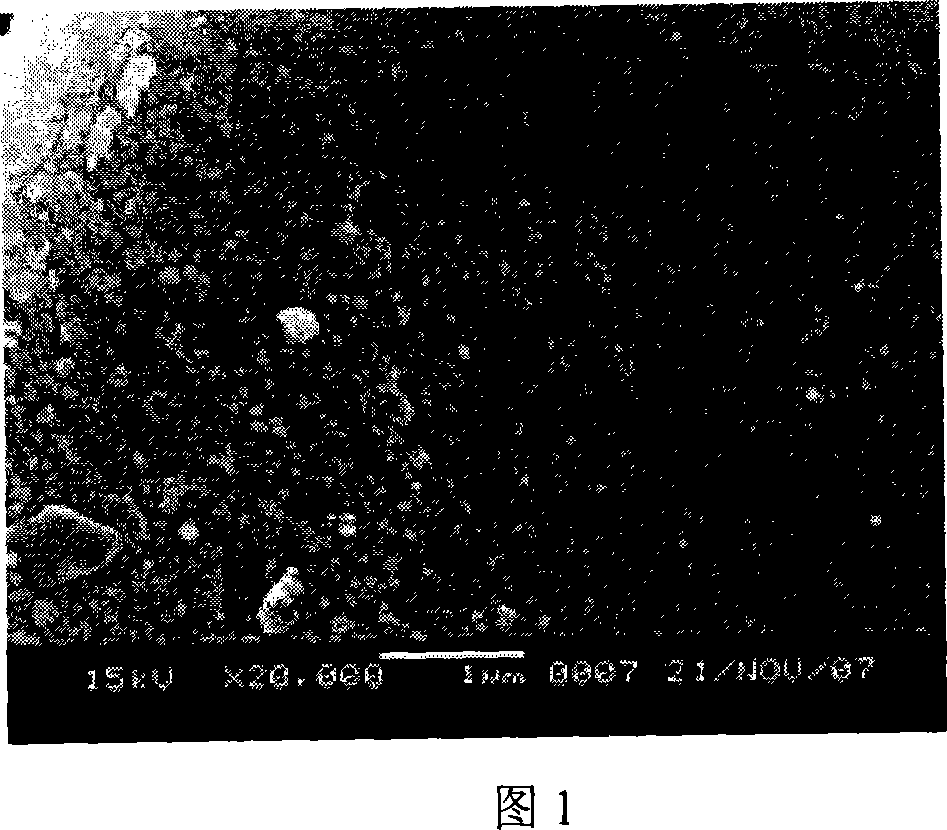

Image

Examples

Embodiment 1

[0026] (1) Add 23.5g of polyacrylonitrile (PAN) powder into 100ml of N,N-dimethylacetamide (DMAc) solvent, swell at 0-15°C for 4 hours, slowly heat to 70°C in a water bath, and continue stirring for 2h, A PAN solution was obtained. The multi-walled carbon nanotube (MWNT) obtained by oxidation of 0.705g mixed acid (the mixing volume ratio of concentrated nitric acid and concentrated sulfuric acid is 1:3) is dispersed in 35ml DMAc through an ultrasonic cell pulverizer to obtain a carbon concentration of 0.0201g / ml. The nanotube suspension is then blended with the PAN solution, stirred at room temperature for 4h, filtered and defoamed, and the PAN / MWNT spinning with a mass percentage of MWNT of 3% (the mass percentage of carbon nanotubes relative to polyacrylonitrile) is obtained. stock solution.

[0027] (2) The polyacrylonitrile composite fiber with 3% MWNT mass percentage prepared by wet spinning of the above spinning stock solution, wherein the spinning temperature is 30°C, ...

Embodiment 2

[0031] (1) The method is the same as in Example 1, the multi-walled carbon nanotubes are replaced by single-walled carbon nanotubes (SWNT), and the solvent is dimethylformamide.

[0032] (2) The polyacrylonitrile composite fiber with 0.1% SWNT mass percentage prepared by wet spinning of the above spinning stock solution, wherein the spinning temperature is 30°C, the aperture of the spinneret hole is 0.08mm, and the temperature of the coagulation bath is 25°C, The coagulation bath composition is 40%DMF / H 2 O solution, the drawing speed is 5-20m / min, stretching 10 times.

[0033] (3) Same as Example 1, obtain SWNT reinforced carbon fiber.

Embodiment 3

[0035] (1) method is the same as embodiment 1, and solvent is 50% sodium thiocyanate aqueous solution.

[0036] (2) The polyacrylonitrile composite fiber with MWNT mass percentage of 20% is prepared by wet spinning of the above spinning stock solution, wherein the spinning temperature is 30°C, the aperture of the spinneret hole is 0.08mm, and the temperature of the coagulation bath is 25°C, The composition of the coagulation bath is 15% sodium thiocyanate aqueous solution, the drawing speed is 5-20 m / min, and the drawing is 6 times.

[0037] (3) Same as Example 1, obtain MWNT reinforced carbon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com