Graphene-based barrier composite material and preparation method thereof

A technology of graphene-based and composite materials, applied in the field of graphene-based nano-barrier composite materials and its preparation, and graphene-based nano-barrier composite materials, which can solve high investment costs, difficult process control, complex molding machinery and mold design, etc. problems, to achieve the effect of superior comprehensive performance, improved Young's modulus, strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

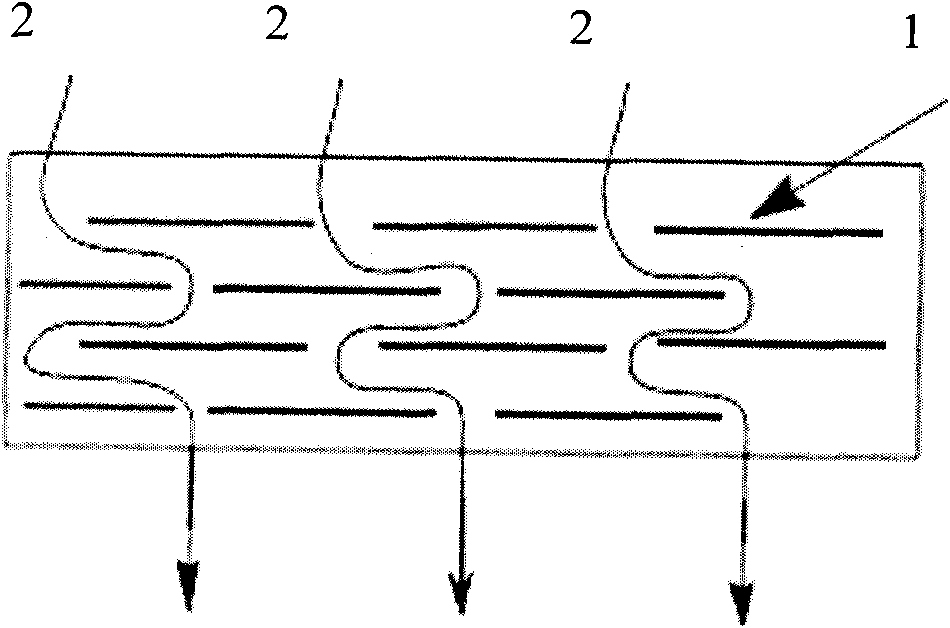

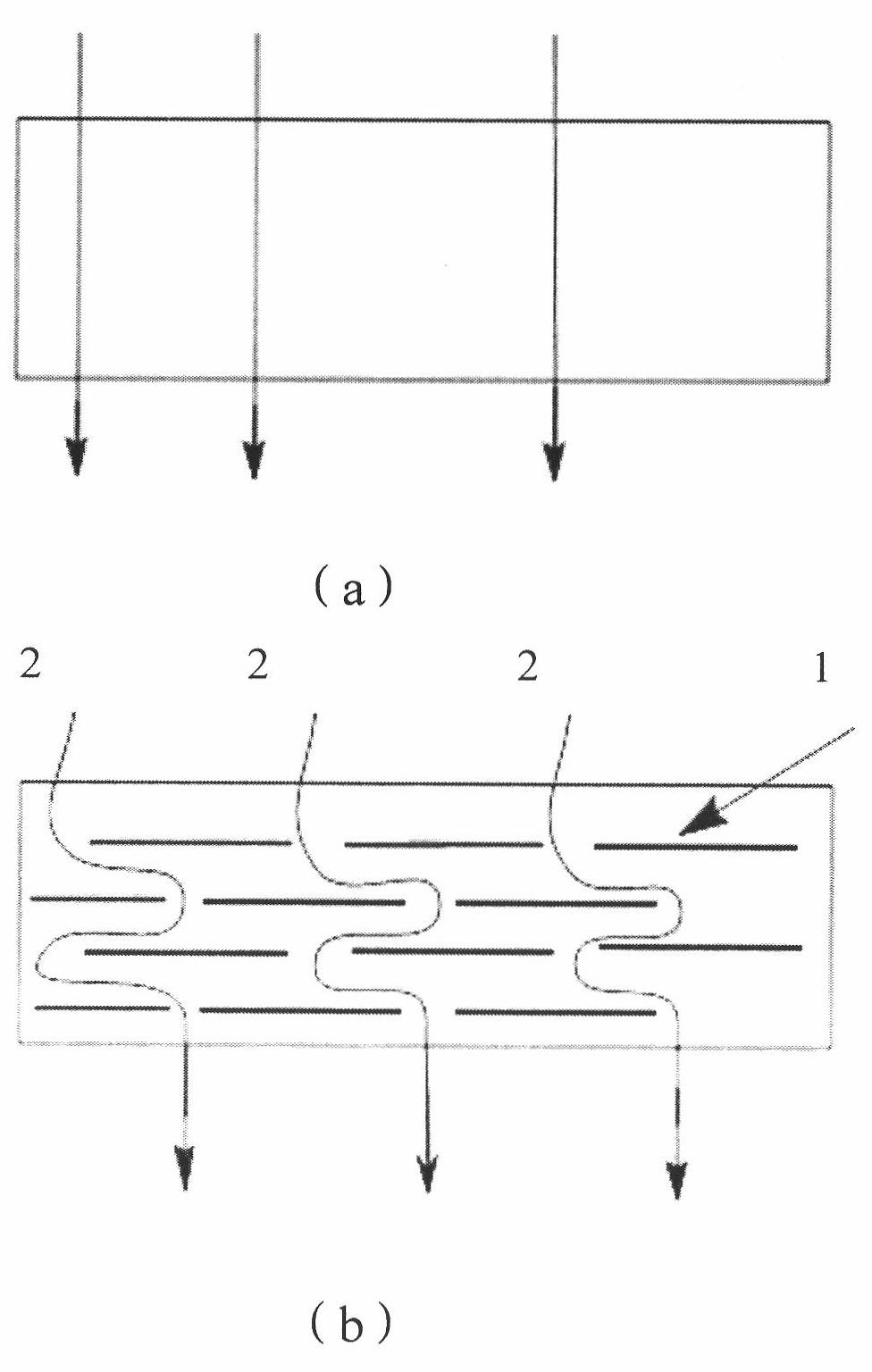

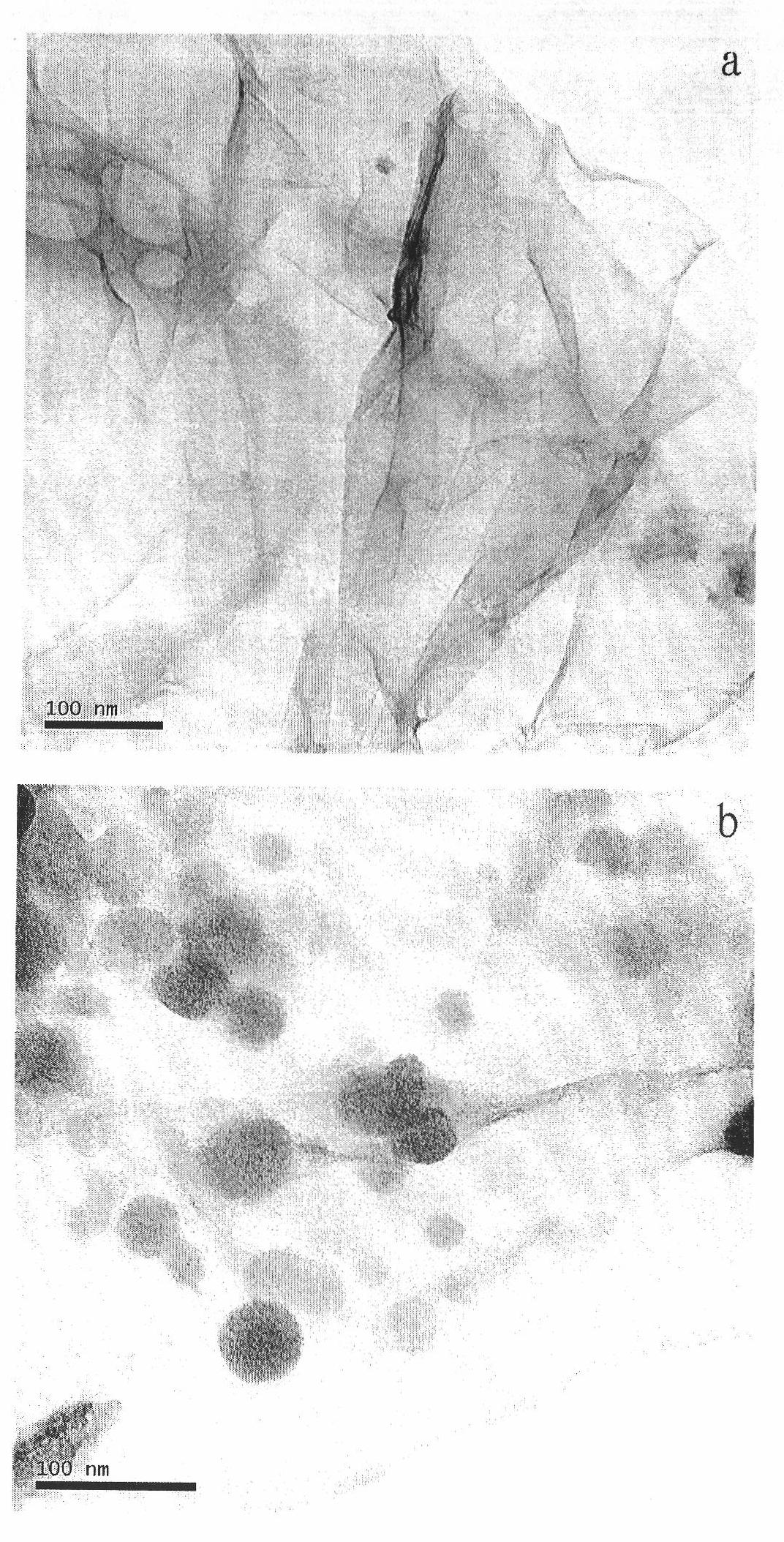

[0029] Example 1 The first step, functional modification of graphene: first disperse 0.4 g of graphene oxide in 100 ml of deionized water, and ultrasonically make it completely dispersed for 30 minutes at a frequency of 100 Hz. Then, under magnetic stirring, add 10 ml of vinyl triethoxysilane, and react for 1 hour at a stirring speed of 500 revolutions per minute and a reaction temperature of 90°C. Then add 10 ml of hydrazine hydrate and react for 2 hours. Finally, it is filtered by suction, and the product is repeatedly washed with deionized water and dried in an oven at 60°C for 12 hours.

[0030] The second step, the preparation of graphene-based nano-barrier composite material: first add 30 grams of polypropylene (molecular weight 100,000) to 100 ml of carbon tetrachloride, mechanically stir at 90 ℃ for 1 hour to make it completely dissolved, stirring The speed is 1000 revolutions per minute. Then add 0.2 g of functionally modified graphene and 10 mg of benzoyl peroxide and...

Embodiment 2

[0031] Example 2 followed the preparation method of Example 1, except that the carbon tetrachloride was changed to ethanol (100 ml) and the results shown in Figures 2, 3, 4, and 5 were also obtained.

Embodiment 3

[0032] Example 3 follows the preparation method of Example 1, except that the carbon tetrachloride is changed to N,N-dimethylformamide (100 ml) and the results shown in Figures 2, 3, 4, and 5 are also obtained. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com