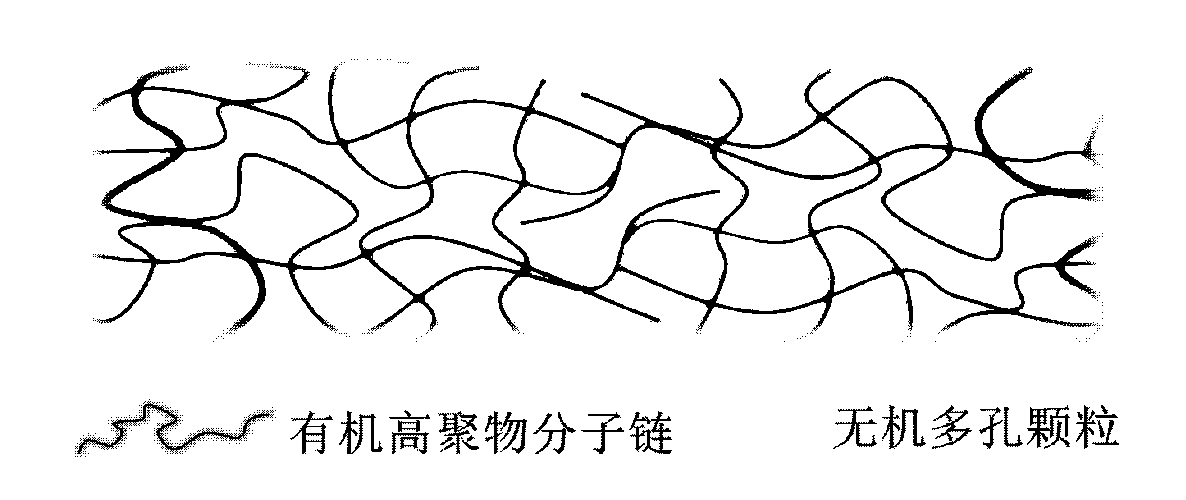

Organic-inorganic composite membrane as well as preparation and application thereof

An inorganic composite and organic technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of increasing the cost of the battery diaphragm, reducing the porosity of the diaphragm, and the twists and turns of the lithium ion channel, achieving high safety performance and reliability. The effect of reducing volatility and avoiding heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

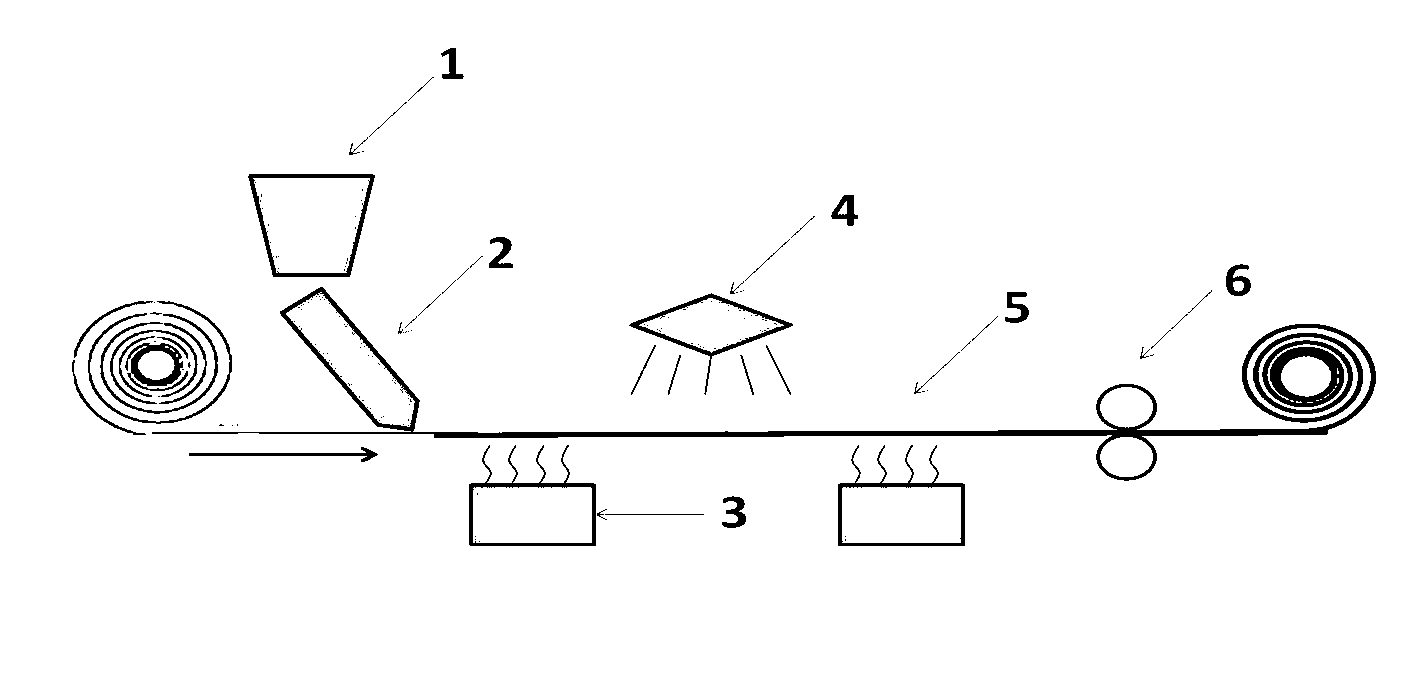

Method used

Image

Examples

Embodiment 1

[0052] For the preparation of the diaphragm, the inorganic particles used are hectorite (lithium magnesium silicate) with a particle size of 10-15nm, the polymer is PVDF (polyvinylidene fluoride) with a molecular weight of 640,000, and the solvent is NMP (N-methylpyrrolidone ) and methanol in a mass ratio of 5:1. According to hectorite:PVDF:solvent=9:1:20 (mass ratio), mix hectorite, PVDF, and solvent at room temperature to form a slurry, pour it on a stainless steel plate, heat and dry it at 150°C for 5 hours, and prepare Composite film with a thickness of 30 μm.

[0053] Configure the electrolyte, using LiPF 6 It is a lithium salt, DMC and EC are solvents, and the configuration composition is DMC·1MLiPF 6 / EC (1:1, w / w) electrolyte. Add this electrolyte dropwise on the surface of the composite membrane, it can be quickly absorbed by the composite and evenly dispersed.

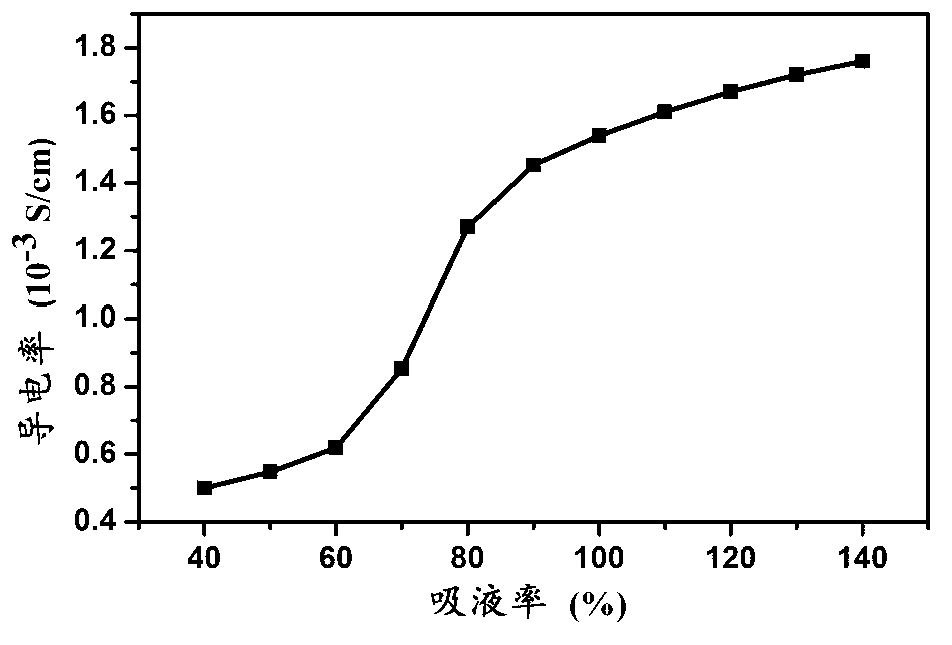

[0054] The liquid absorption rate of this composite membrane can reach 200%. As the liquid absorption ...

Embodiment 2

[0057] For the preparation of the diaphragm, the inorganic particles used are porous silica with a particle size of 40-45nm, the polymer is PVDF with a molecular weight of 3,200,000, and the solvent is NMP. According to porous silica:PVDF:NMP=5:1:10 (mass ratio), porous silica, PVDF, and NMP were mixed into a slurry at room temperature, poured on an aluminum plate, heated and dried at 70°C for 8 hours, and prepared A composite film with a thickness of 30 μm was formed.

[0058] Configure the electrolyte, using LiBOB and LiPF 6 It is lithium salt, DMC, EC and PC are solvents, and the configuration composition is 1MLiBOB / EC·DEC·1MLiPF 6 / PC (1:1:1, w / w / w) electrolyte.

[0059] The highest liquid absorption rate of this composite membrane is 160%, and the conductivity of the electrolyte membrane at 25°C is 1.65×10 when the liquid absorption rate is 100%. -3 S / cm.

Embodiment 3

[0061] For the preparation of the diaphragm, the inorganic particles used are porous aluminum oxide with a particle size of 70-75nm, the polymer is PE (polyethylene) with a molecular weight of 32000, and the solvent is toluene. According to porous aluminum oxide:PE:toluene=20:1:15 (mass ratio), mix porous aluminum oxide, PE, and toluene at 101°C to form a slurry, pour it on a glass plate, and heat it at 100°C Dry for 6 hours to prepare a composite film with a thickness of 30 μm.

[0062] Configure the electrolyte, using LiPF 6 It is a lithium salt, DMC, DEC and PC are solvents, and the configuration composition is DMC·DEC·2MLiPF 6 / PC (1:1:2, w / w / w) electrolyte.

[0063] The highest liquid absorption rate of this composite membrane is 170%, and the conductivity of the electrolyte membrane at 25°C is 1.58×10 when the liquid absorption rate is 100%. -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com