Preparation method of copper-plated graphene reinforced metal-based composite

A technology of copper-plated graphene and composite materials, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problem of no interface structure design, improve interface wettability, and simplify pretreatment process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of copper-coated graphene reinforced metal matrix composite comprises the following steps:

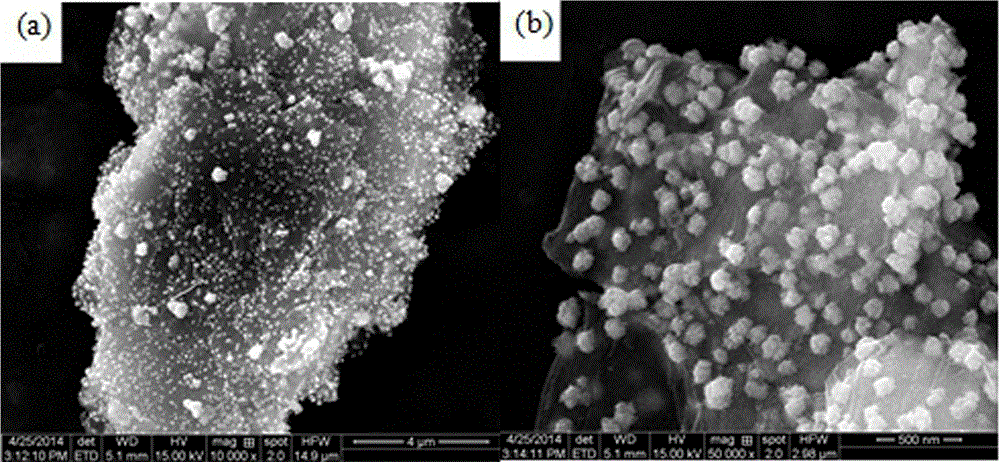

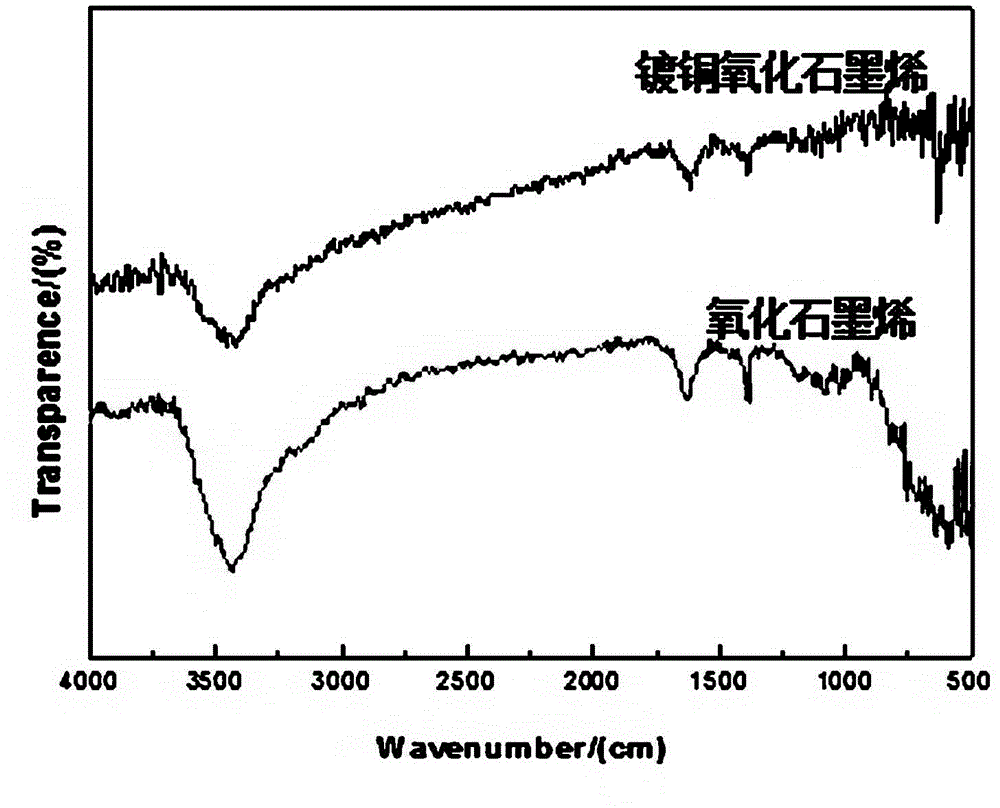

[0045] (1) Chemically copper-plating the surface of graphene oxide powder to obtain copper-coated graphene powder;

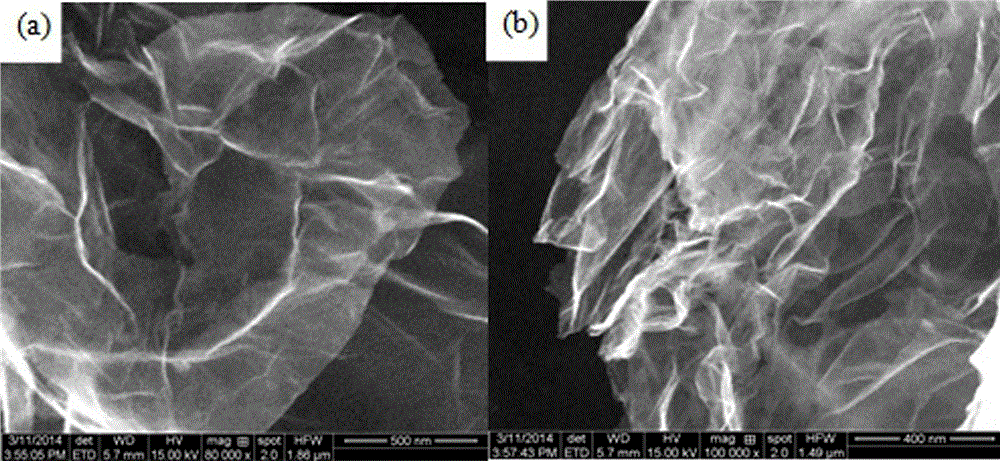

[0046] Graphene oxide powder is prepared by the Hummer method and has a multi-layer hexagonal close-packed graphite structure.

[0047] (2) Mixing copper-coated graphene powder and metal powder by ball milling to obtain copper-coated graphene / metal mixed powder;

[0048]The mass percentage composition of copper-coated graphene powder in the copper-coated graphene / metal mixed powder is 0.1wt%; Ball milling parameter: vacuumize before ball milling, argon or nitrogen protection, ball material ratio 3:1, rotating speed 350r / min, Ball milling time 30min.

[0049] The metal powder is aluminum powder with a particle size of 2 μm.

[0050] (3) Using the powder metallurgy warm-pressing process, the copper-coated graphene / metal mixed powder is warm...

Embodiment 2

[0061] The preparation method of copper-coated graphene reinforced metal matrix composite comprises the following steps:

[0062] (1) Chemically copper-plating the surface of graphene oxide powder to obtain copper-coated graphene powder;

[0063] Graphene oxide powder is prepared by the Hummer method and has a single-layer hexagonal close-packed graphite structure.

[0064] (2) Mixing copper-coated graphene powder and metal powder by ball milling to obtain copper-coated graphene / metal mixed powder;

[0065] The mass percent composition of copper-coated graphene powder in the copper-coated graphene / metal mixed powder is 1wt%; Ball milling parameter: vacuumize before ball milling, argon or nitrogen protection, ball material ratio 3:1, rotating speed 300r / min, ball milling The time is 50 minutes.

[0066] The metal powder is titanium powder with a particle size of 15 μm.

[0067] (3) Using the powder metallurgy warm-pressing process, the copper-coated graphene / metal mixed powd...

Embodiment 3

[0078] The preparation method of copper-coated graphene reinforced metal matrix composite comprises the following steps:

[0079] (1) Chemically copper-plating the surface of graphene oxide powder to obtain copper-coated graphene powder;

[0080] Graphene oxide powder is prepared by the Hummer method and has a multi-layer hexagonal close-packed graphite structure.

[0081] (2) Mixing copper-coated graphene powder and metal powder by ball milling to obtain copper-coated graphene / metal mixed powder;

[0082] The mass percent of copper-coated graphene powder in the copper-coated graphene / metal mixed powder is 10wt%; Ball milling parameters: vacuumize before ball milling, argon or nitrogen protection, ball-material ratio 3:1, rotating speed 250r / min, ball milling The time is 60 minutes.

[0083] The metal powder is copper powder with a particle size of 40 μm.

[0084] (3) Using the powder metallurgy warm-pressing process, the copper-coated graphene / metal mixed powder is warm-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com