High damping foil dynamic pressure gas bearing filled with metal particles

A technology of dynamic pressure gas bearings and gas bearings, which is applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of easy instability and low damping of foil dynamic pressure gas bearings, and solve the problems of poor reliability and damping The effect of increasing the value and increasing the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

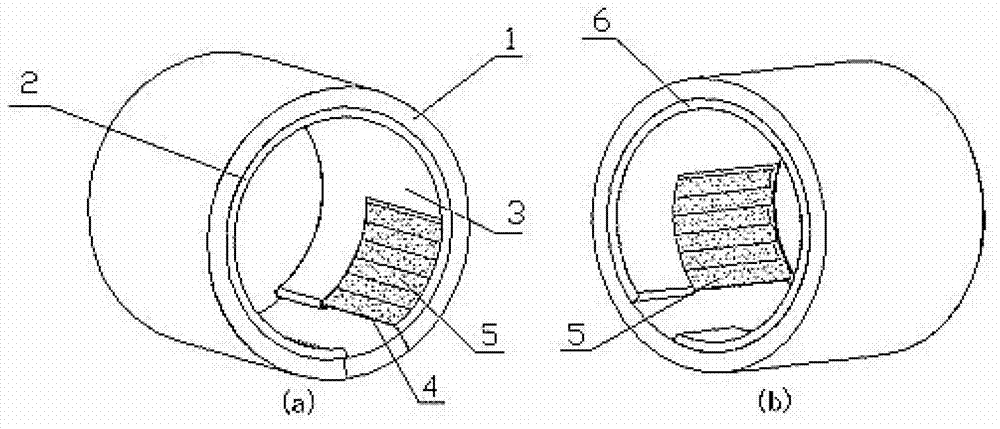

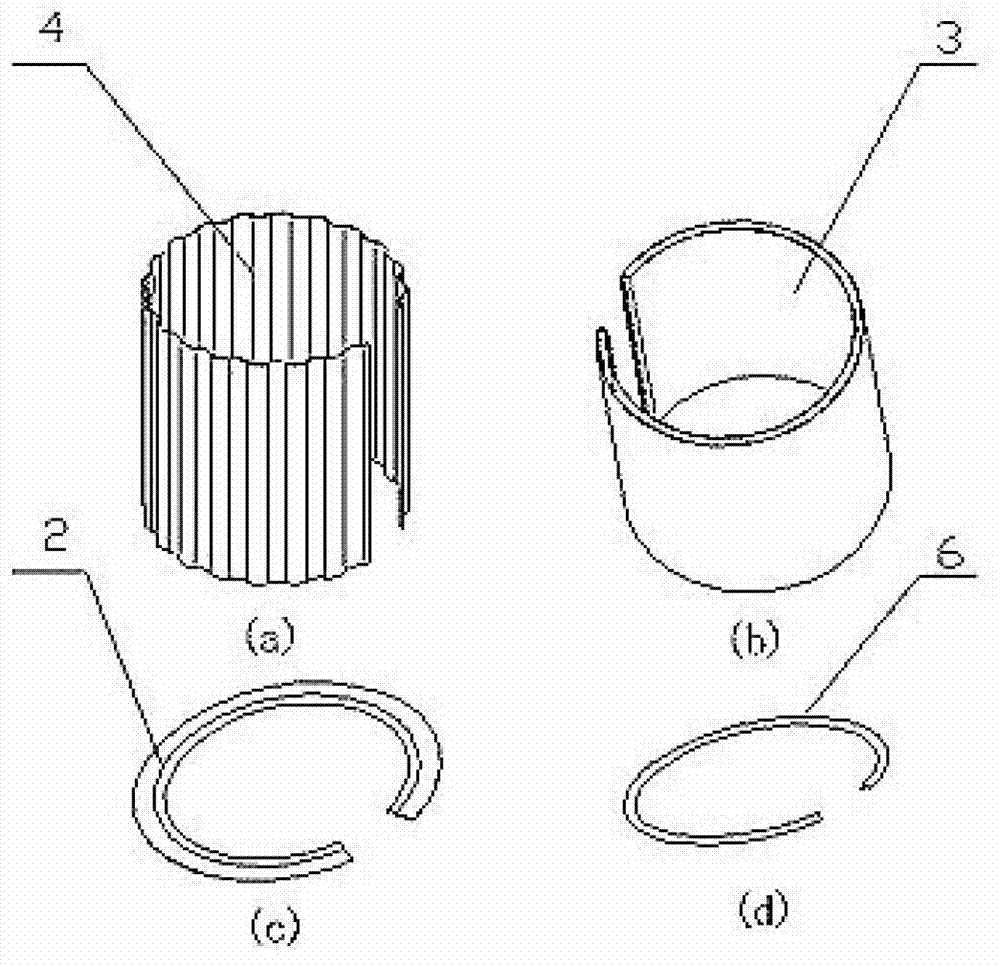

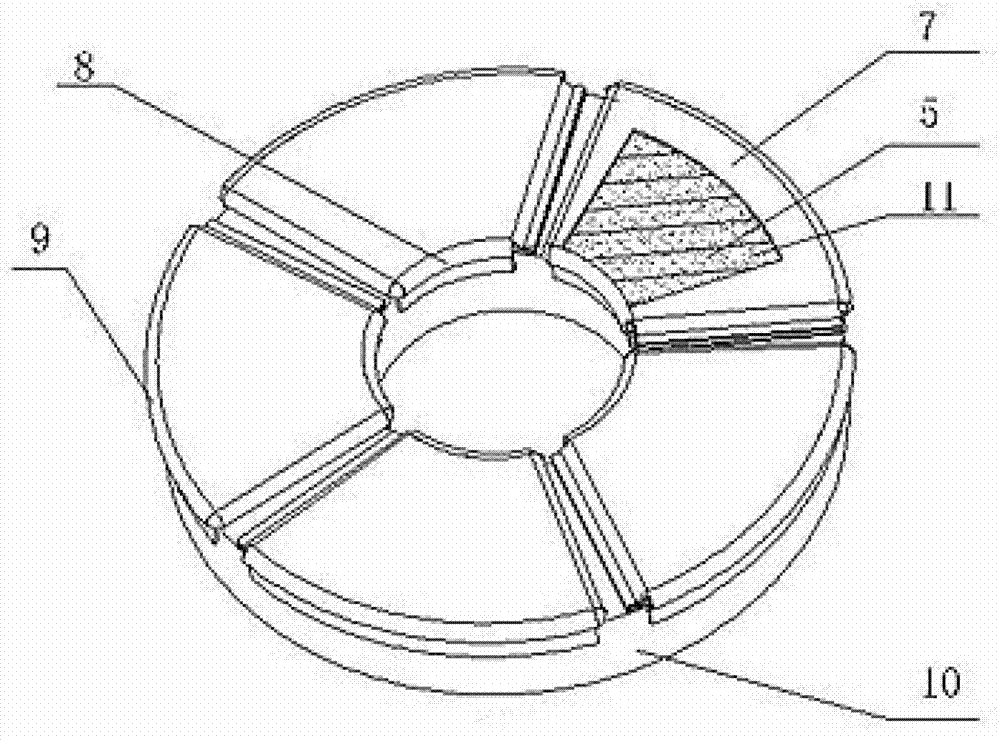

[0015] figure 1 A schematic diagram of a foil dynamic radial gas bearing is shown. In radial bearings, the sleeve foil is formed by folding a piece of foil in half and then curling to form a cylindrical shell structure. The open end is the fixed end, and the folded part is the free end. The opening is connected with an elastic foil and the other end is sealed, and its shape is as figure 2 As shown in middle b; the elastic foil is wave-shaped, and the distance between the peak and the trough is exactly equal to the thickness of the gap in the casing of the foil casing. There is a short flat foil at the fixed end to connect with the foil, and its shape is as follows figure 2 Shown in a. The elastic foils are just able to be contained in the housing cavity of the sleeve foil, and they are welded together on the bearing sleeve at the open end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com