Wide-frequency high-damping vibration isolator

A high damping and vibration isolator technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems that affect the performance of machinery and equipment, harsh environmental conditions, and weak bearing capacity Significant vibration effect, space saving and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0041] The invention provides a broadband high damping vibration isolator.

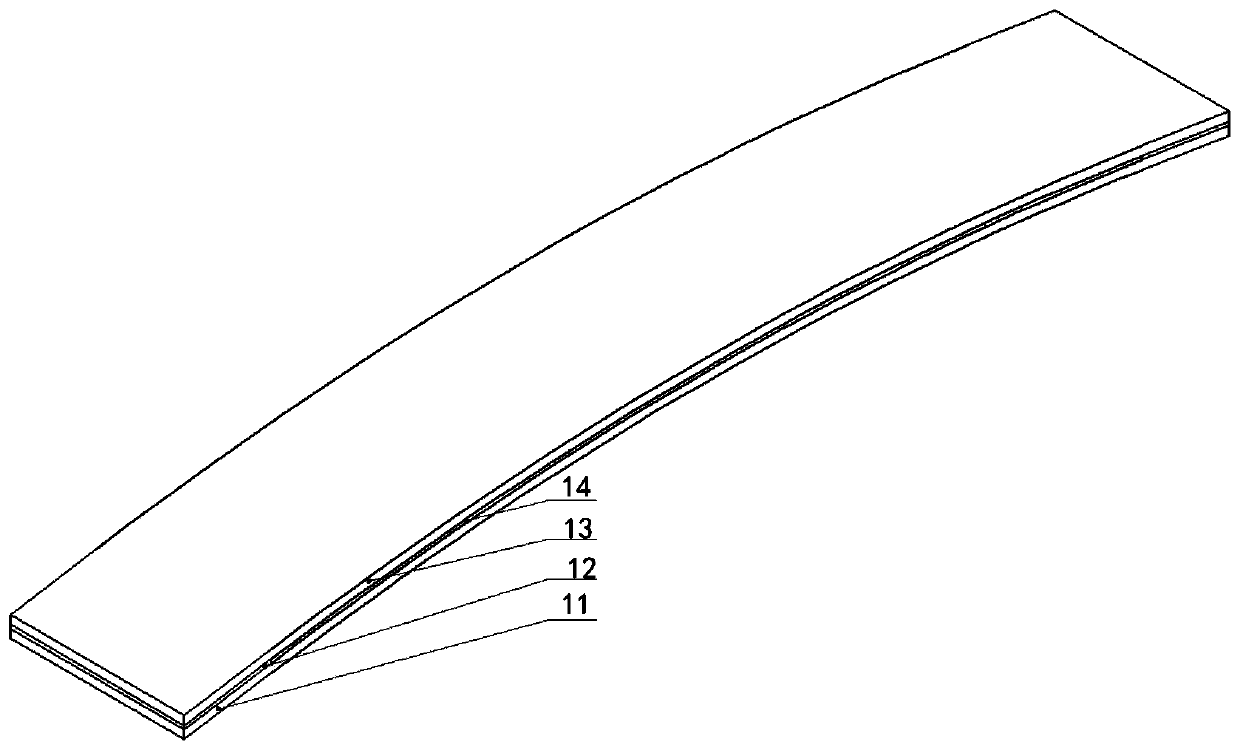

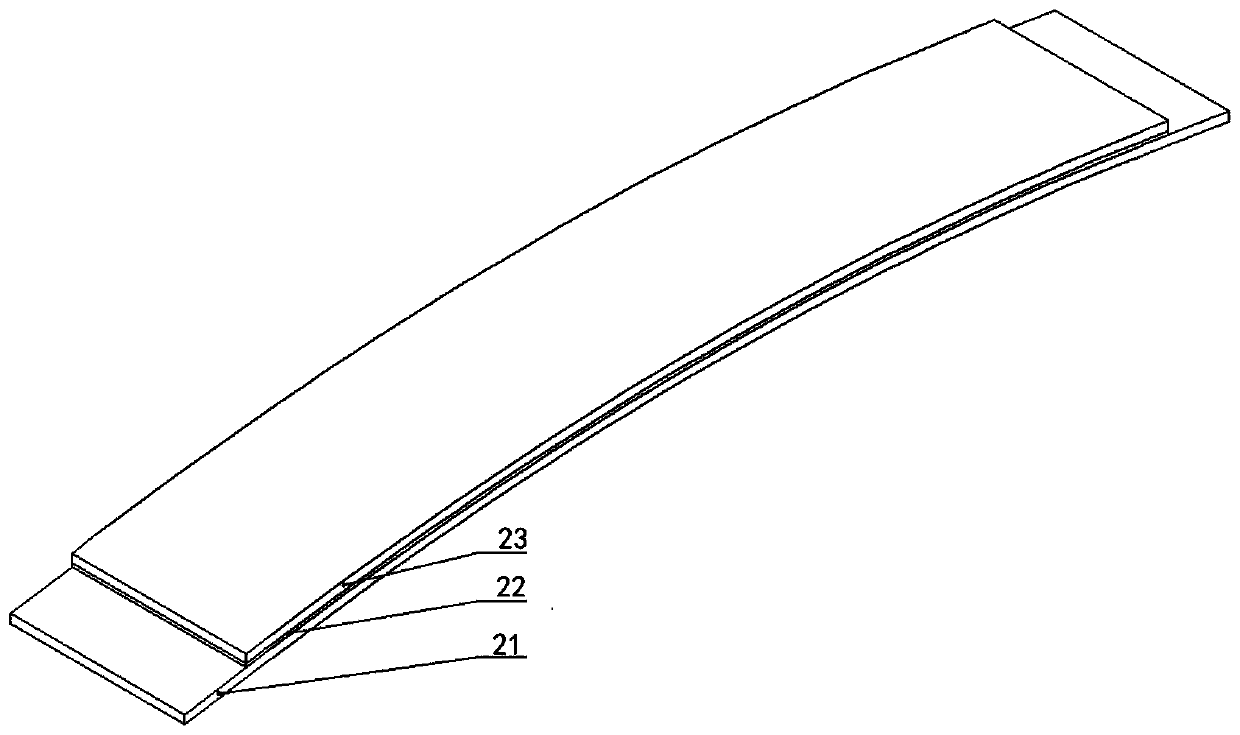

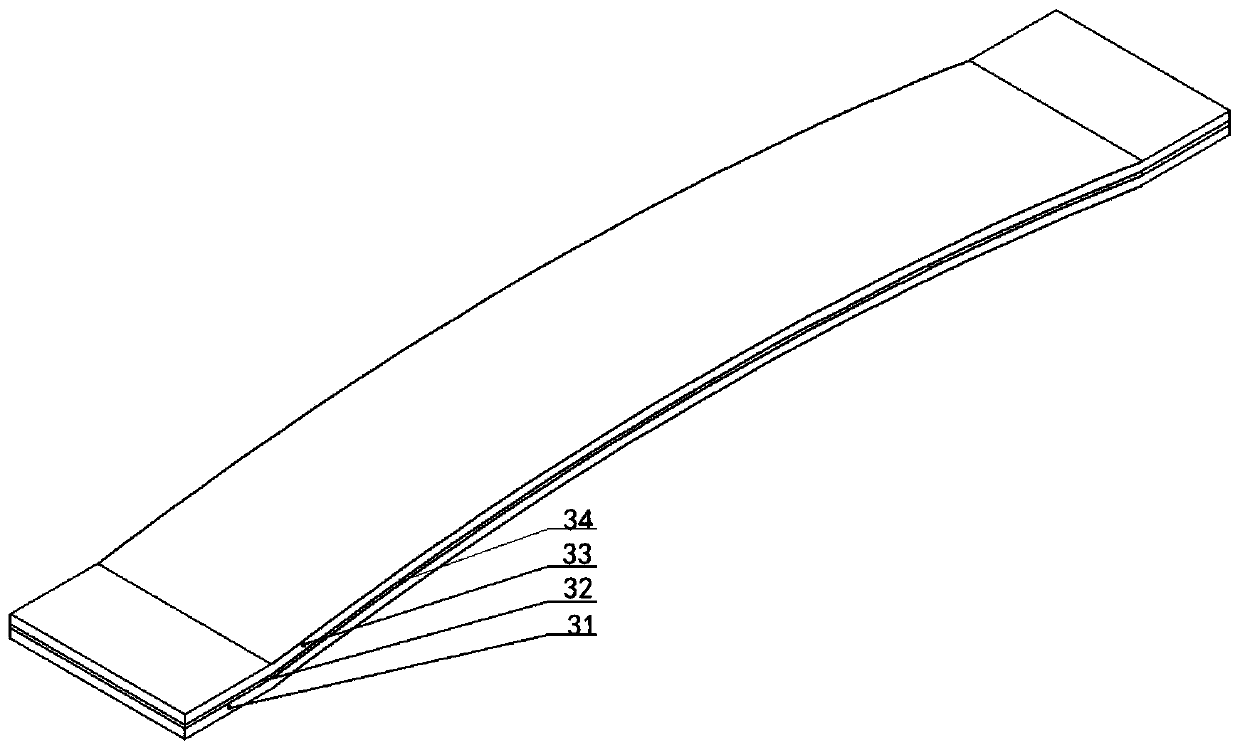

[0042] The vibration isolator includes a supporting composite beam, a connecting boss, an upper equilateral triangular connecting plate and a lower equilateral triangular connecting plate, wherein the supporting composite beam is bonded by a metal gasket, a flexible material gasket and a metal thin-walled beam through an adhesive The three supporting composite beams are symmetrically installed on the outside of the upper equilateral triangular connecting plate and the lower equilateral triangular connecting plate through the connecting bosses in parallel, and the connecting bosses and the upper equilateral triangular connecting plate and the lower equilateral triangular connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com