Aqueous anticorrosive damping coating material for automobile chassis, preparation method and equipment thereof

A technology for damping coatings and automobile chassis, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, mixing methods, etc., can solve the problems of insufficient damping performance of water-based damping coatings, can not meet the needs of use, does not have anti-corrosion and flame retardancy, etc., and achieves improvement. Damping temperature range, easy disassembly and cleaning, and scientific components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

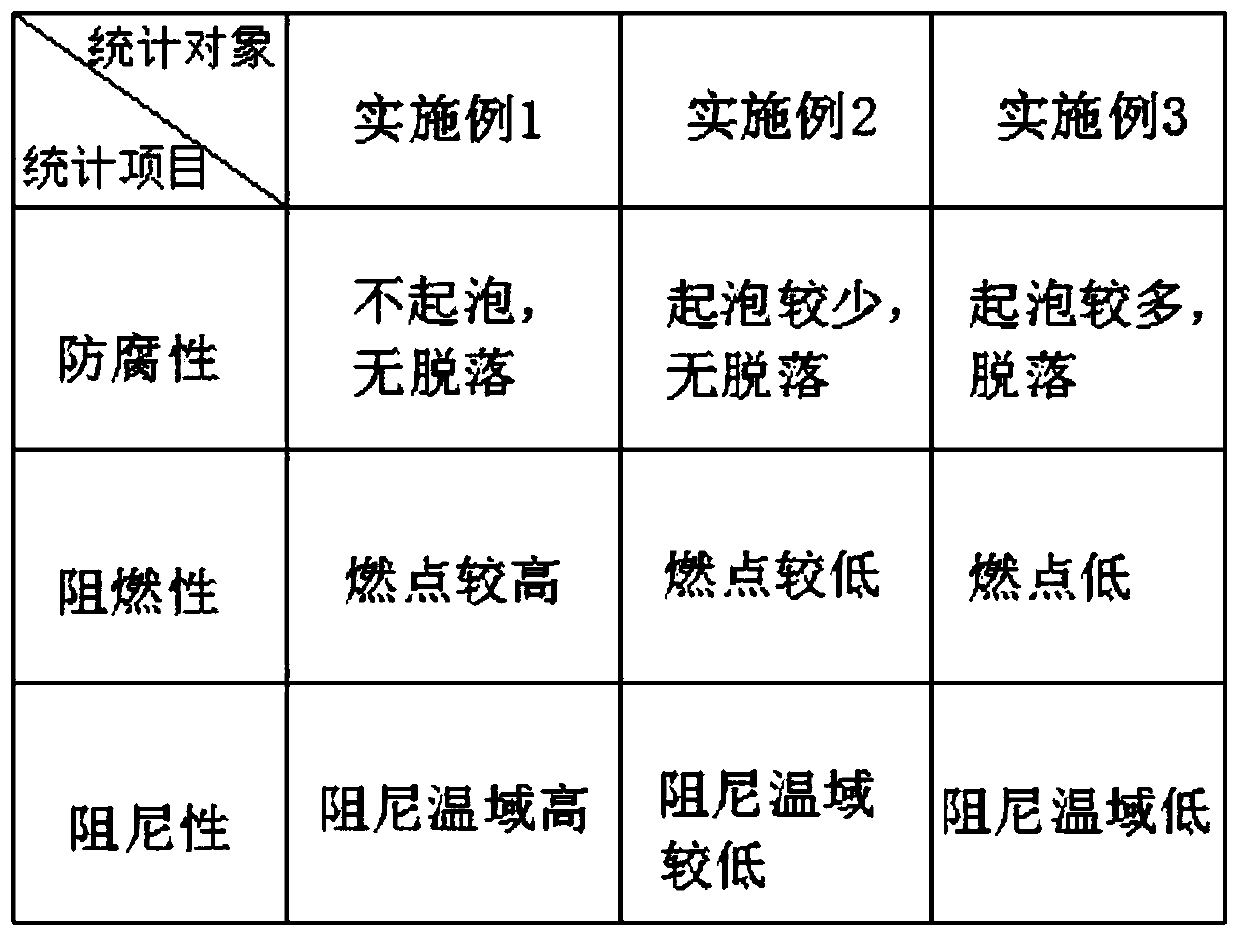

Embodiment 1

[0036] The water-based anti-corrosion damping paint for automobile chassis provided in this embodiment is made of the following components in parts by weight: 55-75 parts of water-based polymer elastic resin emulsion, 30-40 parts of damping pigment and filler, and 20-40 parts of aluminum fiber , 10-20 parts of preservatives, 8-16 parts of flame retardants, 6-10 parts of film-forming aids, 20-30 parts of deionized water, 1-3 parts of thickeners, 0.7-0.9 parts of defoamers, and Compatible agent 2-4 parts, coupling agent 0.6-0.8 parts.

[0037]Specifically, the water-based anti-corrosion damping coating described in this embodiment is made of the following components in parts by weight: 65 parts of water-based polymer elastic resin emulsion, 35 parts of damping pigments and fillers, 30 parts of aluminum fiber, 15 parts of preservative, flame retardant 12 parts of agent, 8 parts of film-forming aid, 25 parts of deionized water, 2 parts of thickener, 0.8 part of defoamer, 3 parts o...

Embodiment 2

[0047] The water-based anti-corrosion damping coating, preparation method and equipment provided in this embodiment are basically the same as in Example 1, except that:

[0048] The water-based anti-corrosion damping coating is made of the following components in parts by weight: 55 parts of water-based polymer elastic resin emulsion, 30 parts of damping pigment and filler, 20 parts of aluminum fiber, 10 parts of preservative, 8 parts of flame retardant, film-forming assistant 6 parts of agent, 20 parts of deionized water, 1 part of thickener, 0.7 parts of defoamer, 2 parts of compatibilizer, and 0.6 parts of coupling agent.

[0049] The preparation method of the aforementioned water-based anti-corrosion damping coating for automobile chassis comprises the following steps:

[0050] S1. First, select 55 parts of water-based polymer elastic resin emulsion, 30 parts of damping pigments and fillers, and 20 parts of aluminum fiber in appropriate proportions and put them into the mi...

Embodiment 3

[0055] The water-based anti-corrosion damping coating, preparation method and equipment provided in this embodiment are basically the same as in Example 1, except that:

[0056] The water-based anti-corrosion damping coating is made of the following components in parts by weight: 75 parts of water-based polymer elastic resin emulsion, 40 parts of damping pigment and filler, 40 parts of aluminum fiber, 20 parts of preservative, 16 parts of flame retardant, film-forming 10 parts of additives, 30 parts of deionized water, 3 parts of thickener, 0.9 parts of defoamer, 4 parts of compatibilizer, and 0.8 parts of coupling agent.

[0057] The preparation method of the aforementioned water-based anti-corrosion damping coating for automobile chassis comprises the following steps:

[0058] S1. First, select 75 parts of water-based polymer elastic resin emulsion, 40 parts of damping pigments and fillers and 40 parts of aluminum fiber in appropriate proportions and put them into the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com