Butyl rubber/poly(meth)acrylate interpenetrating polymer networks damping material and process for preparing same

A butyl rubber and acrylate technology, which is applied in the fields of polymer synthesis and molding processing, can solve the problems of difficult to meet the application requirements of shock absorption and noise reduction, low damping value of polyamide, low damping value in high temperature area, etc. The effect of damping functional area, wide damping functional area, and high damping value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] According to the formula for preparing vulcanized chlorobutyl rubber as shown in Table 1-1, mix chlorinated butyl rubber with 201 phenolic resin, filler carbon black, zinc oxide and other vulcanization aids on a double-roller mixer at a temperature of 60°C Blend evenly, and then press on a press with a temperature of 140-170° C. and a pressure of 5-10 MPa for 10-20 minutes. Then place the vulcanized chlorobutyl rubber in different (meth)acrylate monomers, crosslinking agents and initiator mixtures prepared according to the formula in Table 1-2, soak and swell to achieve a weight gain of 25 to 30%. After the rate, the soaked samples were respectively put into molds, and molded on a press at a temperature of 60-90°C and a pressure of 5 MPa for 4 hours to obtain samples of interpenetrating polymer networks.

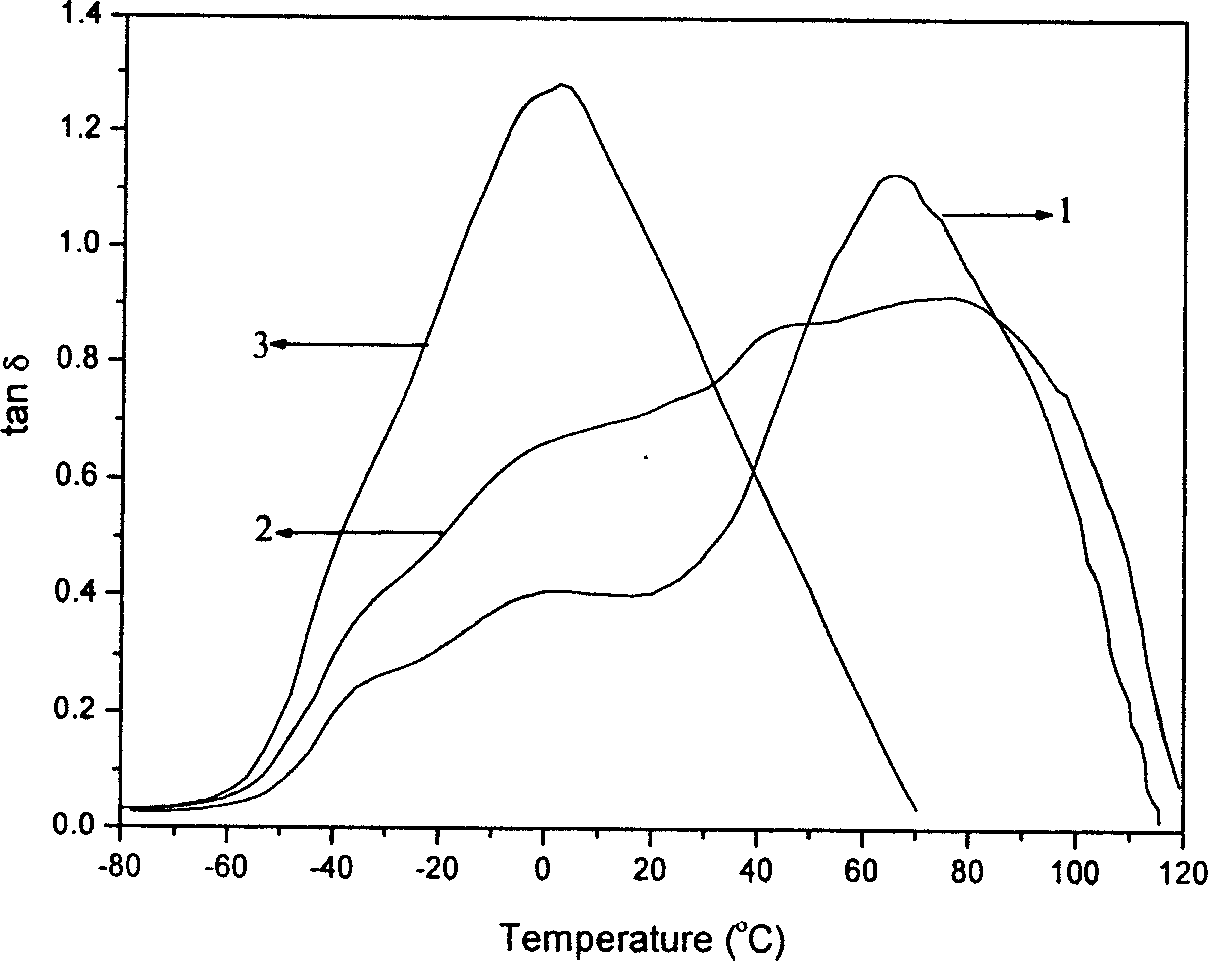

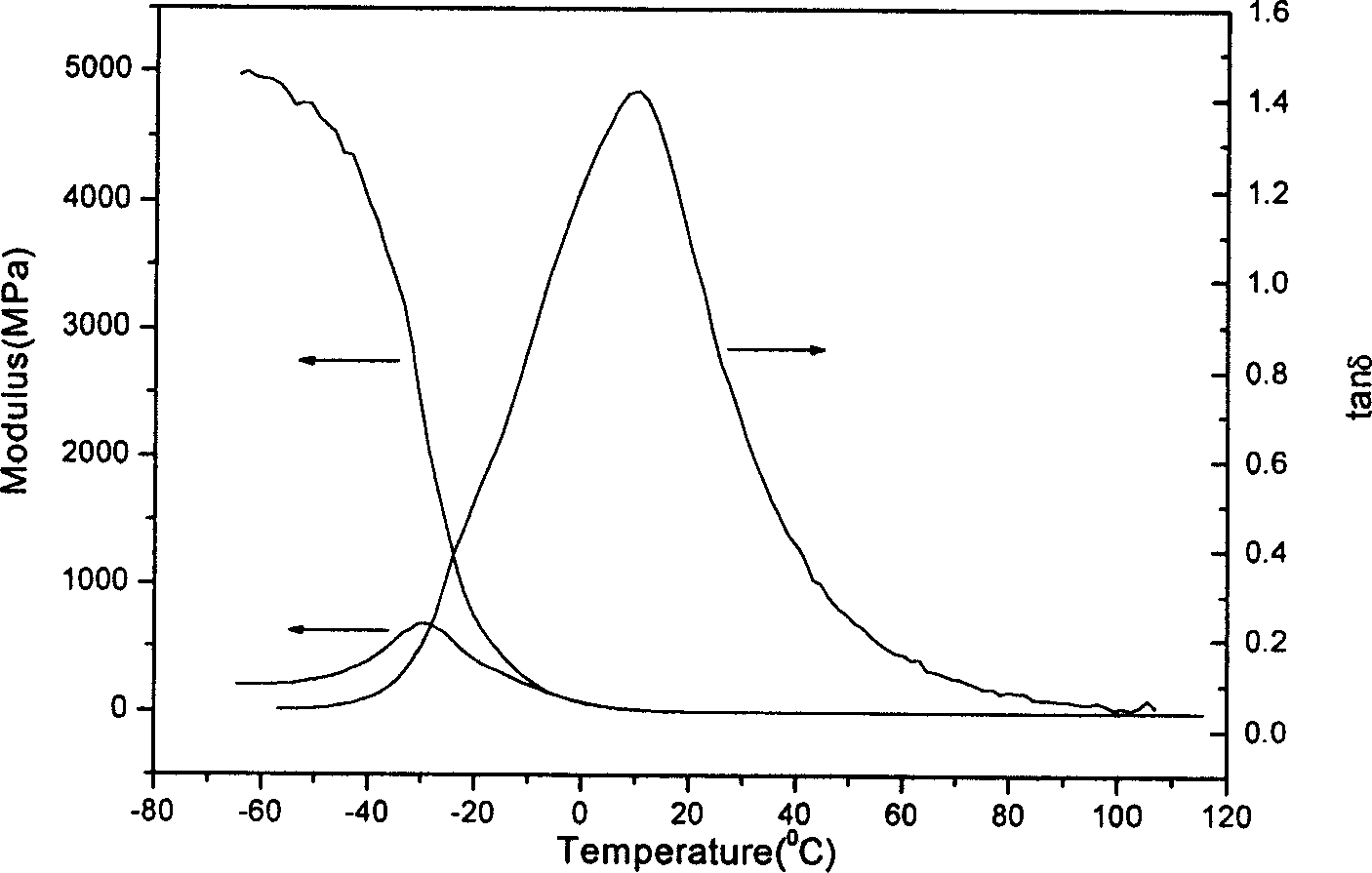

[0032] The damping performance of each interpenetrating polymer network sample is shown in Table 2 and figure 1 , figure 2 shown.

[0033] Table 1 The formula of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com