High-damping silicon rubber

A silicone rubber and high damping technology, applied in the field of high damping silicone rubber, can solve the problems of restricting the development of silicone rubber and low damping value of silicone rubber, and achieve the effects of good shock absorption, high damping value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

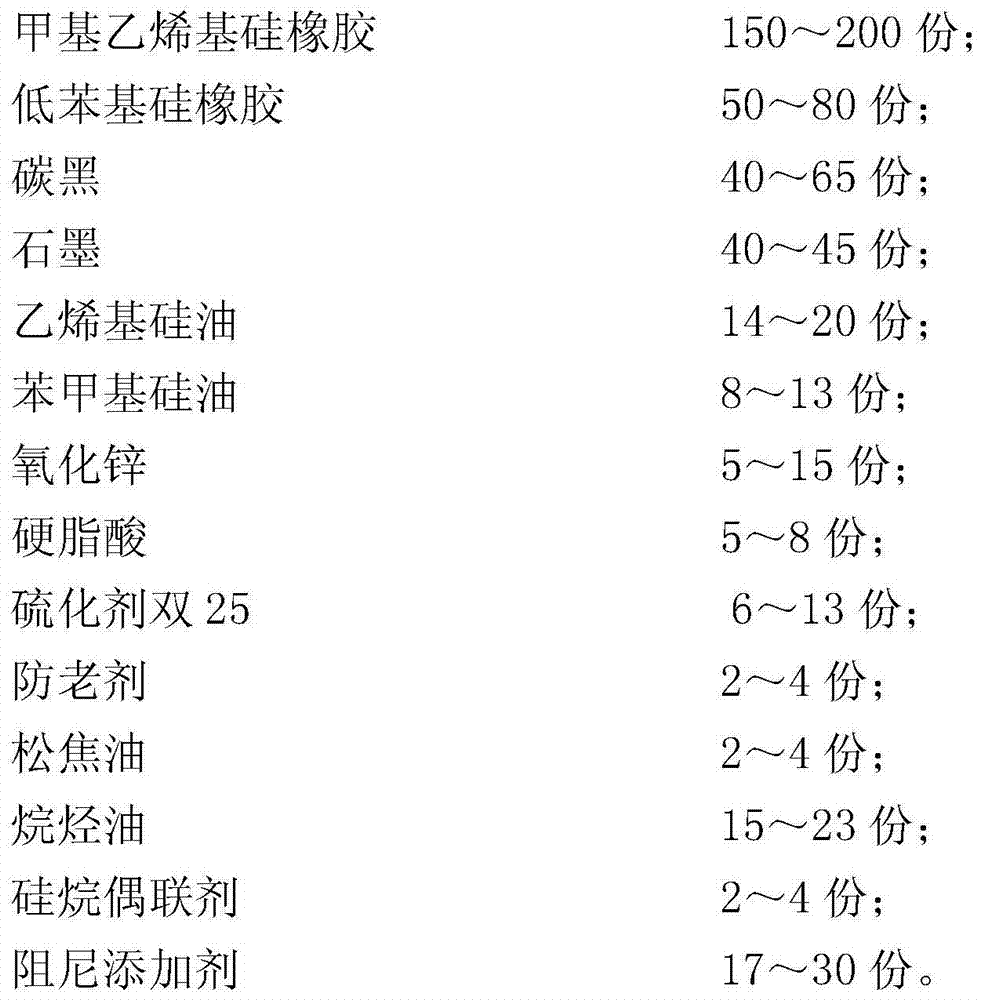

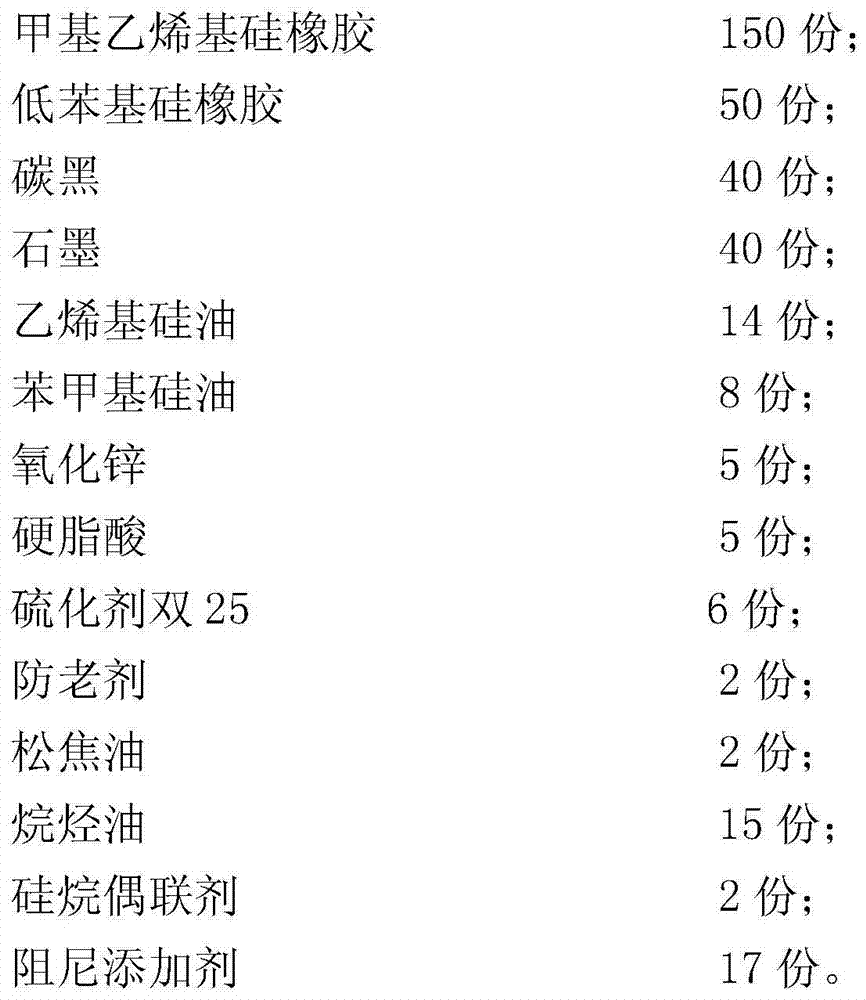

[0012] A kind of high damping silicone rubber, by weight, it comprises the following components,

[0013]

[0014] Among them, the vinyl content of the methyl vinyl silicone rubber is about 0.15 mol%, and the molecular weight is about 600,000. The low phenyl silicone rubber has a phenyl content of approximately 8 mol % and a vinyl content of approximately 0.13 mol %. Since the price of low phenyl silicone rubber is more expensive than methyl vinyl silicone rubber, in order to reduce the production cost, the amount of low phenyl silicone rubber is less than that of methyl vinyl silicone rubber.

[0015] The anti-aging agent is a diaryl secondary amine anti-aging agent.

[0016] The damping additive is a mixture of polysiloxane and polyurethane.

[0017] The preparation method of the high-damping silicone rubber is roughly as follows: by weight, 150 parts of methyl vinyl silicone rubber and 50 parts of low-phenyl silicone rubber are placed on a double-roller rubber mixing m...

Embodiment 2

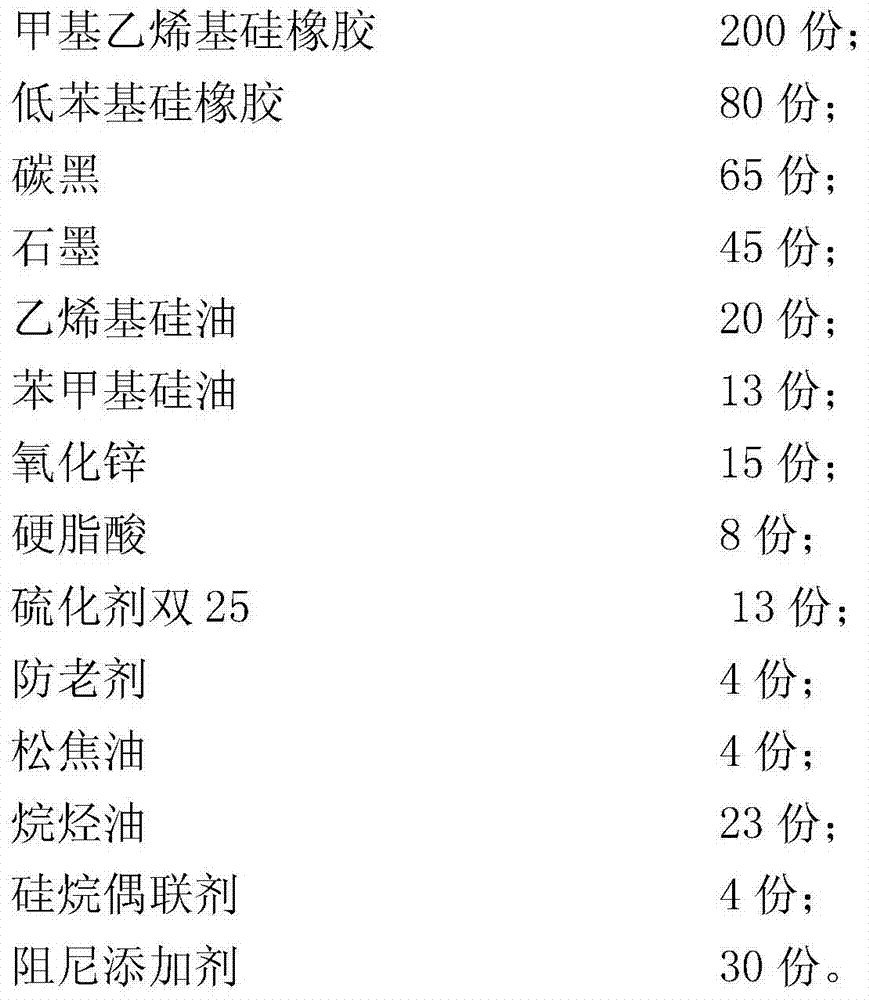

[0019] A kind of high damping silicone rubber, by weight, it comprises the following components,

[0020]

[0021] Wherein the anti-aging agent is p-phenylenediamine anti-aging agent.

[0022] The damping additive is acrylate.

[0023] All the other are with embodiment 1.

[0024] The preparation method of the high-damping silicone rubber is roughly as follows: in parts by weight, 200 parts of methyl vinyl silicone rubber and 80 parts of low-phenyl silicone rubber are placed on a double-roller rubber mixing machine; after wrapping, add 65 parts of carbon black, 45 parts of graphite, 20 parts of vinyl silicone oil, 13 parts of phenylmethyl silicone oil, 15 parts of zinc oxide, 8 parts of stearic acid, 4 parts of antioxidant, 4 parts of pine tar oil, 23 parts of alkane oil, 4 parts of silane coupling agent and 30 parts of damping additive, after kneading, thin pass 2 times to produce the film; then add 13 parts of vulcanizing agent double 25, continue to mix evenly, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com