Environment-friendly thermoplastic composite damping rubber plate for vehicle and preparation method of environment-friendly thermoplastic composite damping rubber plate

A compound damping and thermoplastic technology, which is applied to vehicle parts, chemical instruments and methods, rubber layered products, etc., can solve the problems of unqualified VOC, short shelf life, and poor environmental protection of composite damping materials, so as to improve the utilization rate of materials, Good thermal stability and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

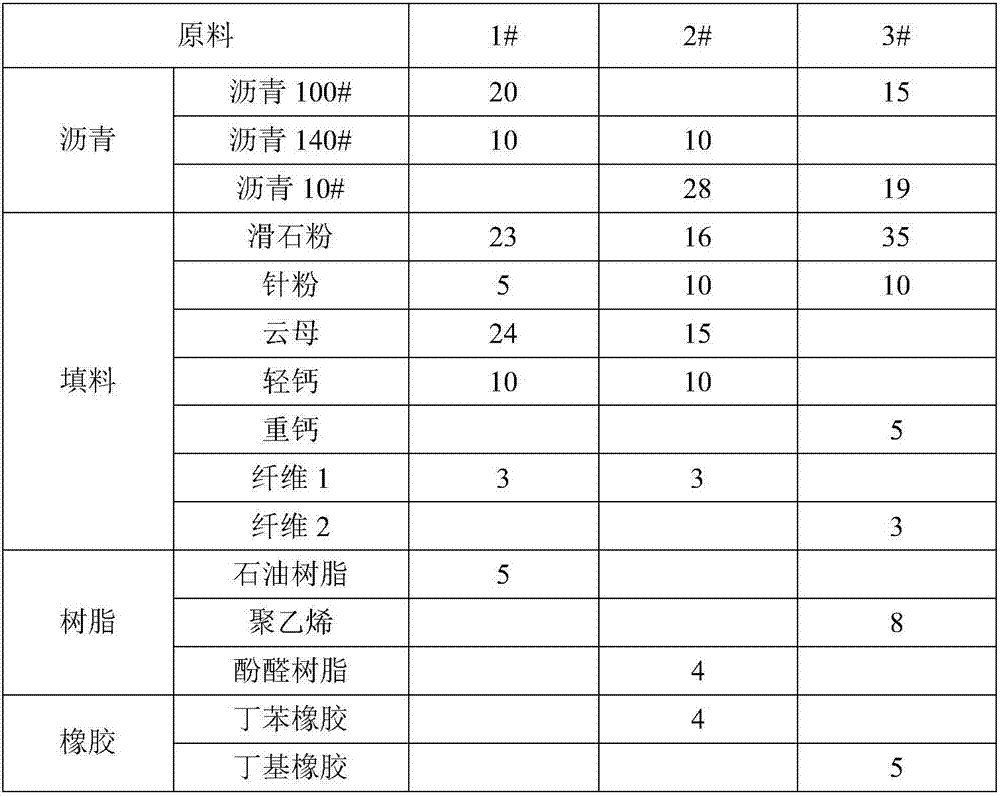

[0020] See 1# in Table 1 for the raw material ratio of the damping laminate, see 1# in Table 2 for the raw material ratio of the bound laminate, and use polybutadiene hot-melt adhesive for the viscoelastic layer.

[0021] First, melt the asphalt at 120-160°C; secondly, add the filler, resin and rubber into the melted asphalt according to the weight ratio and stir evenly; extrude the green block with an extruder; finally, put the green block with a double roller Calender to make sheet

[0022] processing methods:

[0023] 1. Manufacturing process of damping laminates: According to the raw material ratio of 1# in Table 1, heat the asphalt at 160°C to melt, then add filler, resin and rubber to the melted asphalt, extrude and calender to make damping laminates, thickness 2mm.

[0024] 2. The production method of the binding layer:

[0025] Add the 1# raw material in Table 2 into the integrated machine, and adopt the equipment integrating rubber and plastic mixer-hoist-double-co...

Embodiment 2

[0034] The raw material ratio of the damping laminate is shown in Table 1 2#, the thickness is 2.0mm, the raw material ratio of the bonded laminate is shown in Table 2# 2#, the thickness is 3mm, and the viscoelastic layer uses polybutadiene hot melt adhesive with a thickness of 0.7mm. Processing method is with embodiment 1.

[0035] Damping value: 0.06 at 20°C; 0.15 at 40°C; 0.07 at 70°C.

Embodiment 3

[0037] The raw material ratio of the damping laminate is 3# in Table 1, and the thickness is 2mm. The raw material ratio of the restraint laminate is 3# in Table 2, and the thickness of the restraint laminate is 2mm. The viscoelastic layer uses polyurethane hot melt adhesive, and the thickness of the viscoelastic layer is 0.6 mm. Processing method is with embodiment 1

[0038] Damping value: 0.06 at 20°C; 0.08 at 40°C; 0.07 at 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com