Preparation method of a co-cured high damping composite material

A technology of composite materials and damping materials, which is applied in the field of material science, can solve the problems of structural rigidity and strength reduction, and the damping layer is easy to peel off from the structure, so as to achieve the effect of improving the damping performance and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

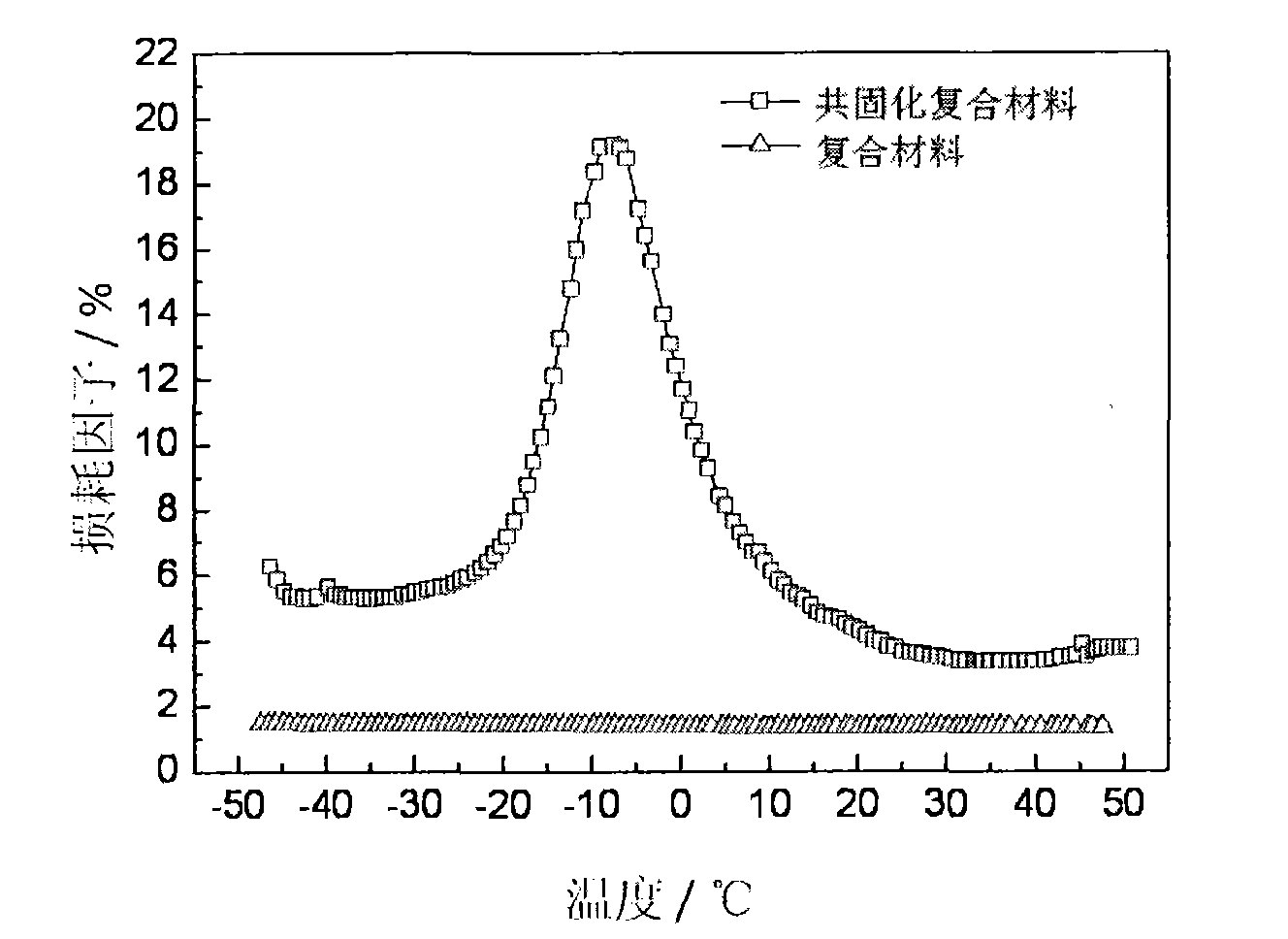

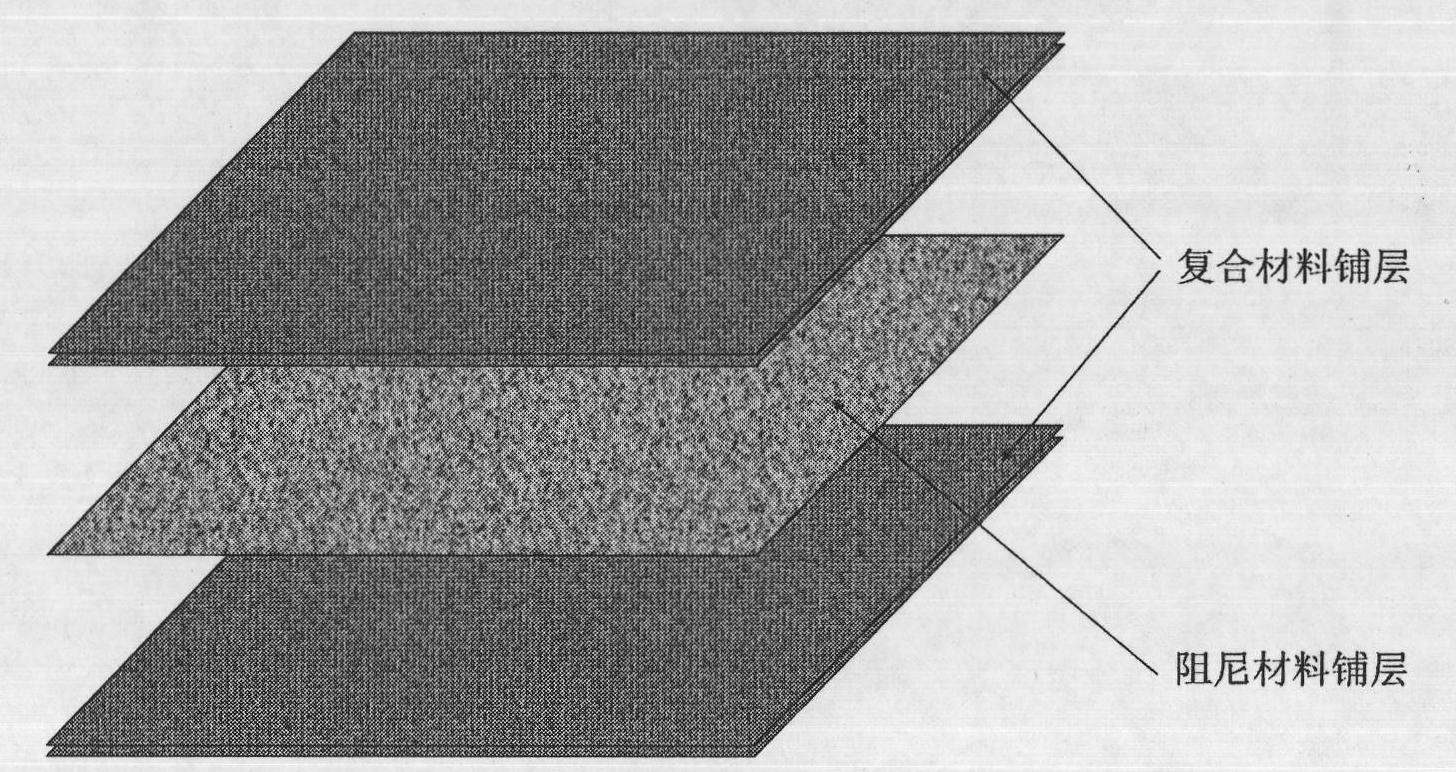

[0011] Example 1: Combining image 3 , a kind of preparation method of co-curing high damping composite material of the present invention, adopts the nitrile rubber that thickness is 0.3mm as the viscoelastic damping material, the composite material prepreg is T700 carbon fiber / epoxy resin 16 layers, the nitrile rubber layer It is laid between the 8th and 9th layers of composite material prepreg. The nitrile rubber layer and the composite material prepreg are co-cured by using the autoclave process and setting the temperature and pressure according to the curing conditions of the epoxy resin. Co-cured high damping composites. The tensile modulus of the nitrile rubber is 114.02GPa, and the modulus of the composite material prepreg without damping layer is 119.36GPa.

Embodiment 2

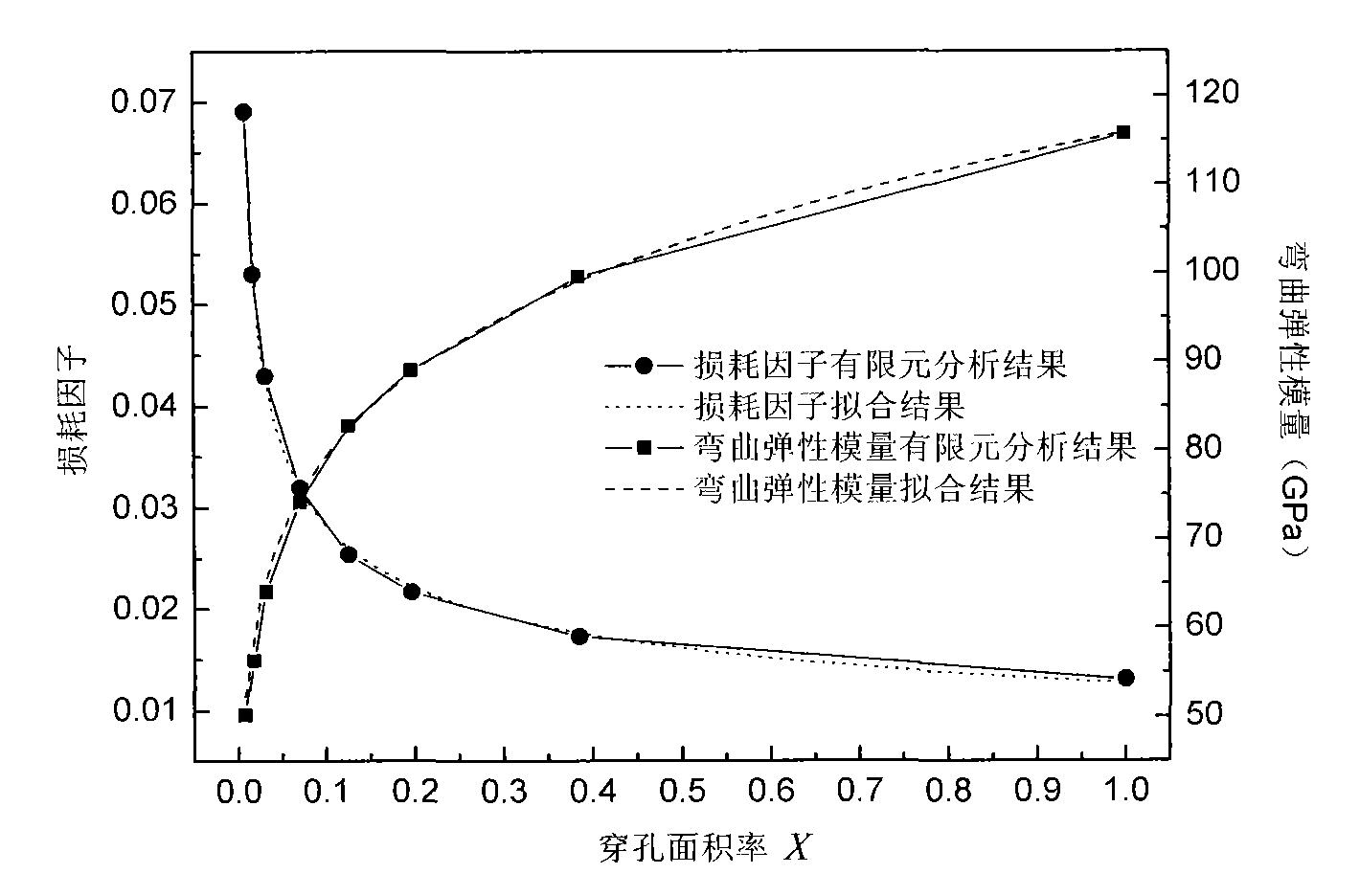

[0012] Example 2: Combining Figure 1-Figure 3 , The technical scheme adopted in the present invention is: prepare the viscoelastic damping material (such as rubber) into a rubber film whose thickness is equivalent to that of a single layer of composite material (or fiber fabric, prepreg). First, use acetone to remove the release agent and other substances remaining on the surface of the damping film, and then use certain tools to polish the surface of the damping film to make the surface of the damping film rough. The film is embedded in the composite material as a specific layer, and the viscoelastic damping diaphragm is cured together with the composite material to form a new type of composite material. The curing conditions of the composite material are set according to the curing process parameters provided by the resin supplier to set the curing temperature and pressure. Since the composite material contains a separate damping layer, the purpose of effectively improving...

Embodiment 3

[0013] Example 3: Binding Figure 1-Figure 3 , the invention can effectively improve the damping performance of the composite material while ensuring the strength and stiffness of the composite material, the damping material is not easy to peel off during use, and basically does not affect the mechanical properties and molding process of the resin-based composite material.

[0014] The nitrile rubber with a thickness of 0.3mm is used as the viscoelastic damping material, and the composite material prepreg (T700 carbon fiber / epoxy resin) has 16 layers, and the nitrile rubber layer is laid between the 8th and 9th layers of the prepreg. The nitrile rubber layer and the composite material are co-cured by using the autoclave process, setting the temperature and pressure according to the curing conditions of the epoxy resin, and co-curing to obtain a new viscoelastic damping layer co-cured composite material. The tensile modulus of the composite material with the nitrile rubber damp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com