Damping composite type variable rigidity vibration attenuating support for gearbox of wind powered generator

A technology for wind turbines and vibration damping supports, which is applied to wind turbine components, wind engines, wind power generation, etc., which can solve the problem of ensuring the limit torque of low-speed shafts, low ability to install and operate errors, and reduce the difficulty of vibration damping support operations and other issues, to achieve the effect of light weight, reduced transmission, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

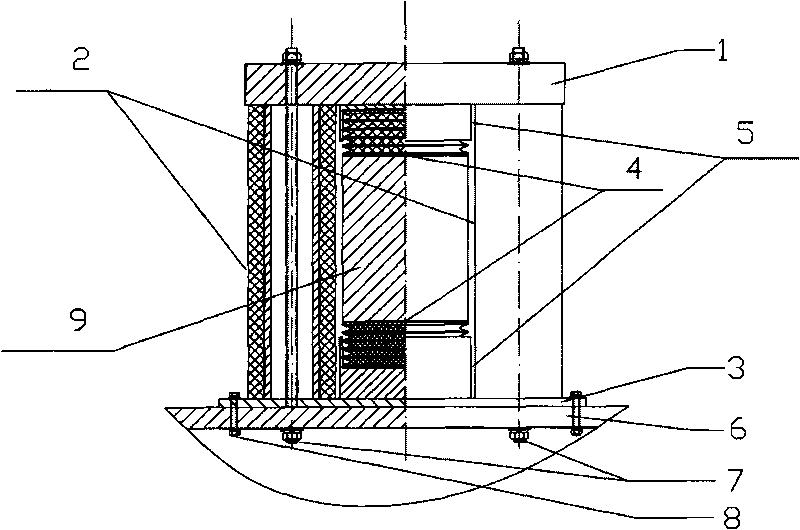

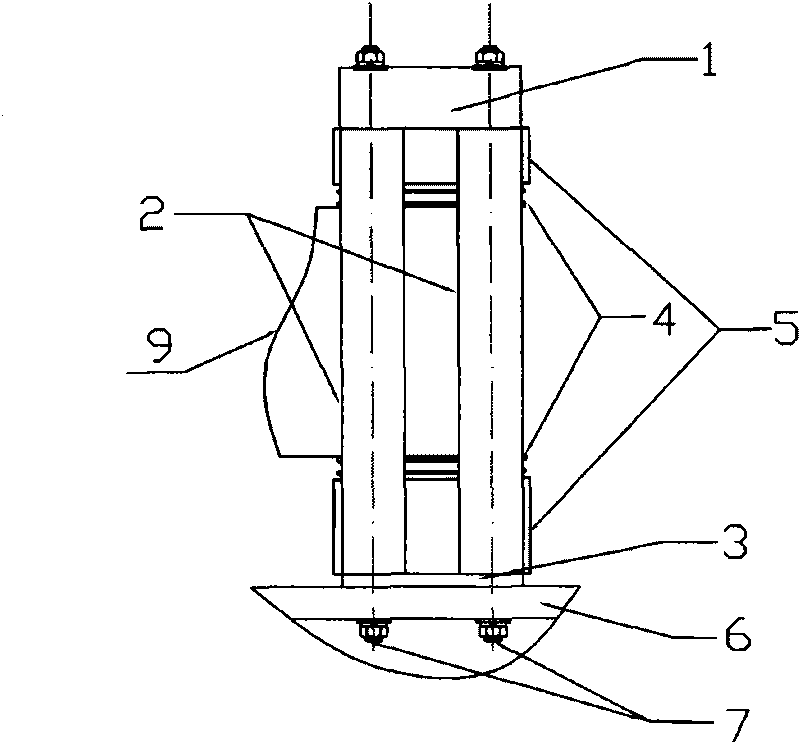

[0022] figure 1 , figure 2 The gearbox involved in the present invention is shown as a damping composite variable stiffness damping support. An upper yoke 1, four columns 2, and a lower yoke 3 are connected through a double-ended screw 7 to form a combined main frame for vibration damping support. , the four uprights 2 are symmetrically distributed two on the left and right sides, and a base 5 is respectively fixed in the middle of the upper yoke 1 and the lower yoke 3, and the base 5 and the upper and lower yokes can be bonded by threaded structure or welding or adhesive Equally connected, the elastic body 4 is housed inside the base.

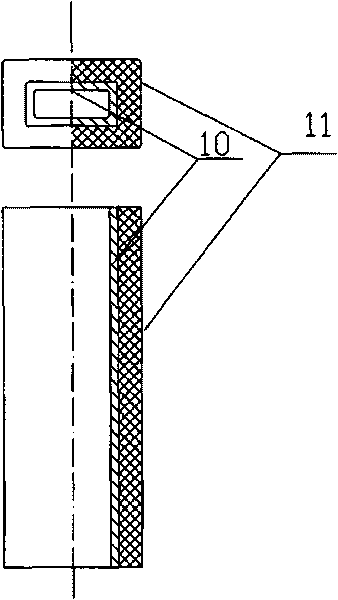

[0023] image 3 Shown is a schematic cross-sectional view of an example structure of the column 2 . The internal part of the column 2 is a metal skeleton 10, which is a hollow structure, and the cross-section can be rectangular, circular, trapezoidal, etc., and can also be a gradual shape, which can greatly reduce the weight of the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com