Foamed aluminum and viscoelastic damping composite material and preparation method

A technology of damping composite materials and damping materials, which is applied in the field of shock-absorbing and noise-reducing materials, can solve problems such as material vibration and noise reduction, and achieve excellent mechanical properties and high damping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

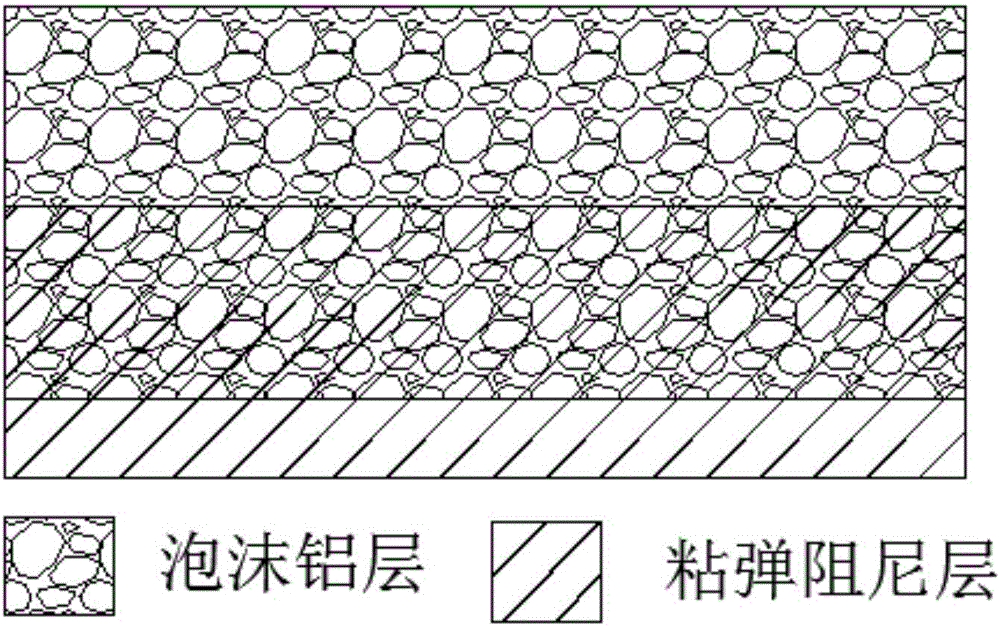

Embodiment 1

[0038] The aluminum foam is prepared into a square of 400mm*400mm*20mm, cleaned with acetone and placed in a vacuum drying oven for later use. Take BaryskinV61 type viscoelastic damping material, mix and prepare according to the ratio required by the product, and then pour the premix into the mold. Insert the aforementioned aluminum foam into the mold and make the aluminum foam about 3-5mm away from the bottom of the mold, and immerse the whole board in the premix solution for about 10mm. The mold was cured in a dry environment at room temperature. After the damping material is completely cured, an aluminum foam / viscoelastic damping composite material is obtained.

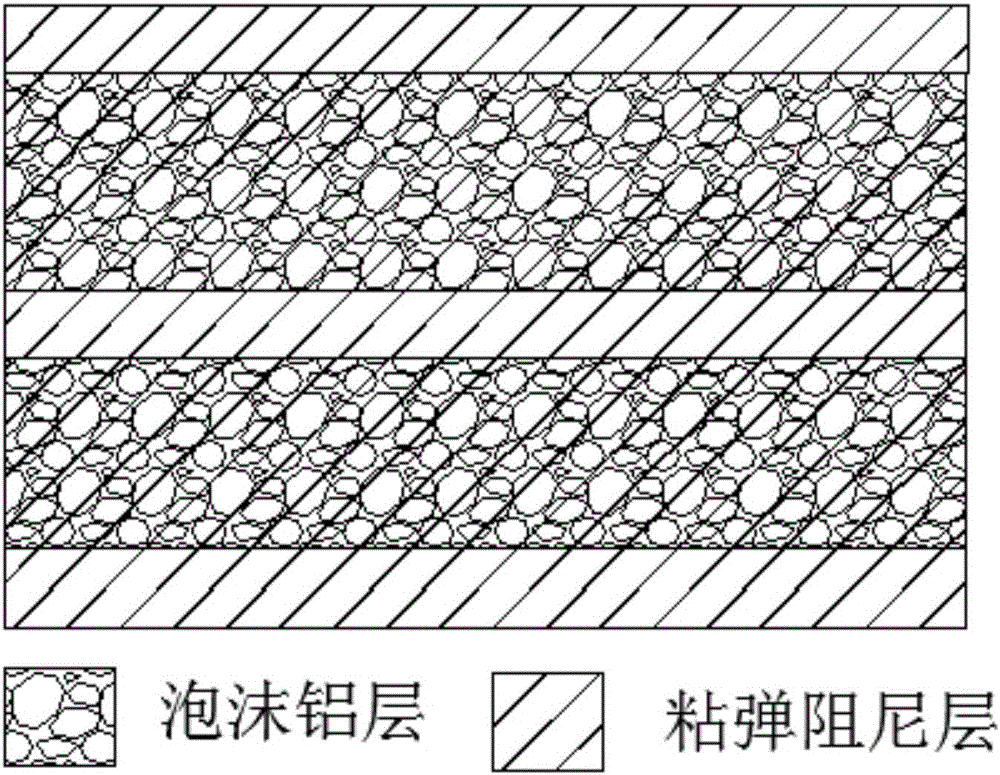

Embodiment 2

[0040] The aluminum foam is prepared into a square of 400mm*400mm*10mm, cleaned with acetone and placed in a vacuum drying oven for later use. Take the SikaPU-RED type viscoelastic damping material, mix and prepare according to the required proportion of the product, and pour the premix into the mold. Insert the aluminum foam mentioned above into the mold and completely immerse the aluminum foam in the premix liquid about 2mm from the liquid surface. The mold was cured in a dry environment at room temperature. Two pieces of cured aluminum foam / viscoelastic composite damping material are stacked, and SikaPU-RED type viscoelastic damping material is used for compounding and a pressure of 0.1 MPa is applied on the stack. After the damping material is completely cured, a multi-layer aluminum foam / viscoelastic composite damping material is prepared.

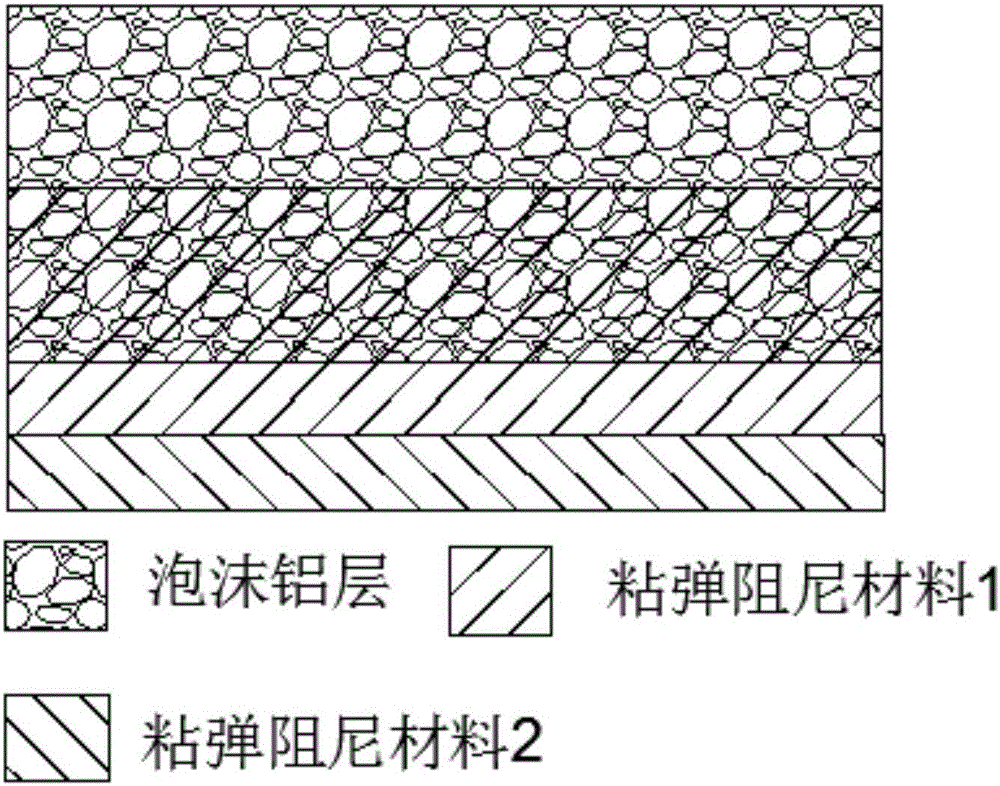

Embodiment 3

[0042] The aluminum foam is prepared into a square of 400mm*400mm*10mm, cleaned with acetone and placed in a vacuum drying oven for later use. Take the BaryskinV607 type viscoelastic damping material, mix and prepare according to the ratio required by the product, and then pour the premix into the mold. Embed the aluminum foam mentioned above into the mold, so that the aluminum foam is immersed in the premix solution for about 5mm. The mold was cured in a dry environment at room temperature. After the damping material is completely cured, an aluminum foam / viscoelastic damping composite material is obtained. On the surface of the viscoelastic damping material of the composite material, a layer of 2 mm thick Air++3101 type viscoelastic damping material was compounded and placed at room temperature for curing. After the damping material is completely cured, an aluminum foam / multilayer viscoelastic damping composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com