Infrastructure large-load multidirectional vibration isolation and reduction device and disaster prevention method thereof

An infrastructure and multi-directional technology, which is applied in the field of multi-directional vibration isolation devices for large loads of infrastructure, can solve problems such as weak vertical vibration damping capacity, weak carrying capacity, and poor energy consumption capacity, and achieve large carrying capacity and work The effect of stable performance and enhanced structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

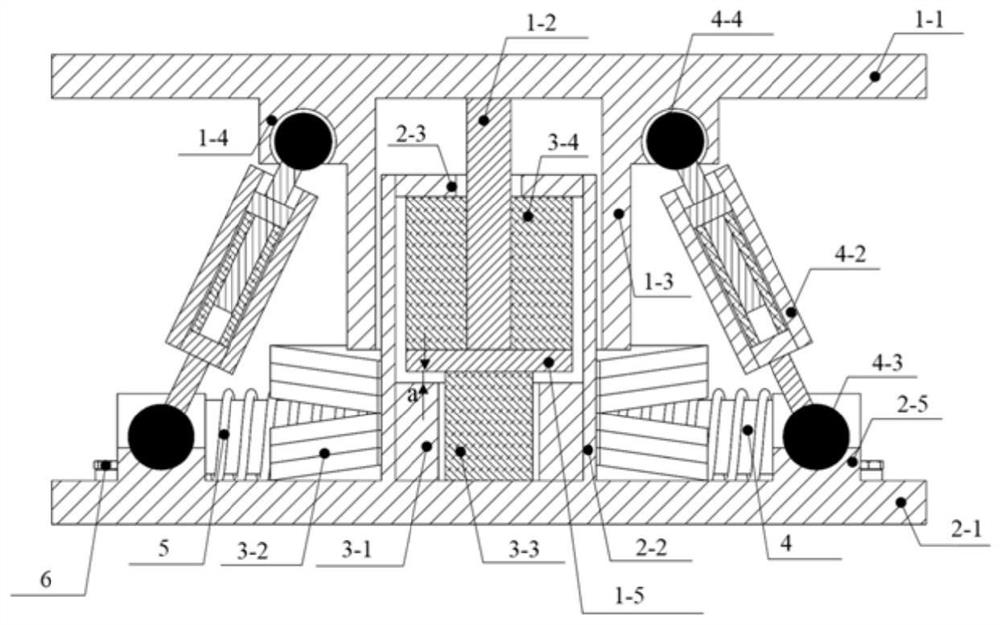

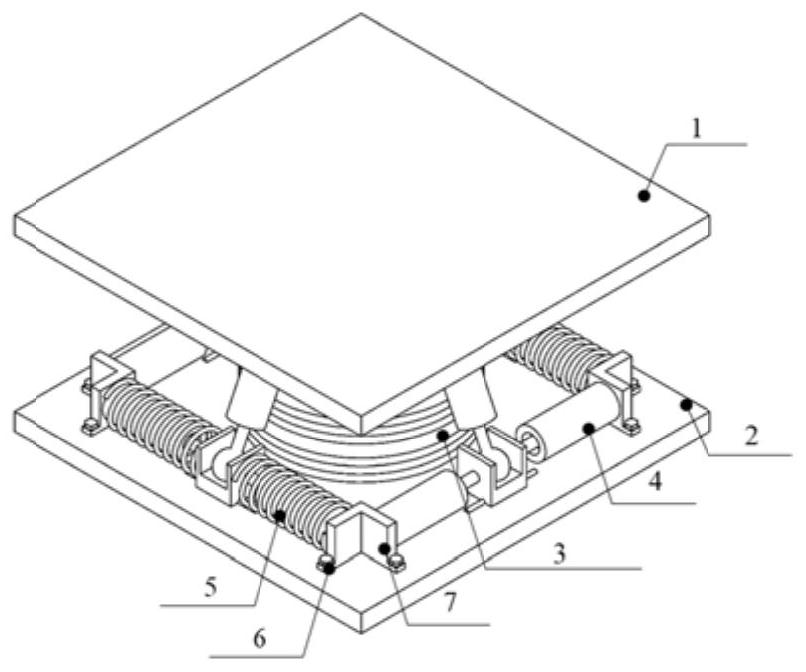

[0080] Such as figure 1 , figure 2 and image 3 As shown, what the present invention describes is a multi-directional vibration isolation and damping device for large loads of infrastructure. Partial composition. The vertical vibration damping part 3 is located at the center of the base 2 and plays a role of vertical vibration damping. The horizontal shock absorbing parts 4 are arranged in pairs in the horizontal direction, evenly distributed outside the vertical shock absorbing parts 3 , and connected to the base 2 through bolts 6 and fixed end plates 7 . The helical steel spring 5 is sleeved on the horizontal shock absorbing part 4, and jointly plays the role of shock absorbing in the horizontal direction.

[0081] Such as figure 1 and figure 2 As shown, the upper end cover 1 includes a top plate 1-1, a pressing shaft 1-2, a pressing cylinder 1-3 and a reserved connecting piece 1-4.

[0082] The finale shaft 1-2 is located at the center of the top plate 1-1 and is T...

Embodiment 2

[0097] In this embodiment, the helical steel spring 5 is omitted.

Embodiment 3

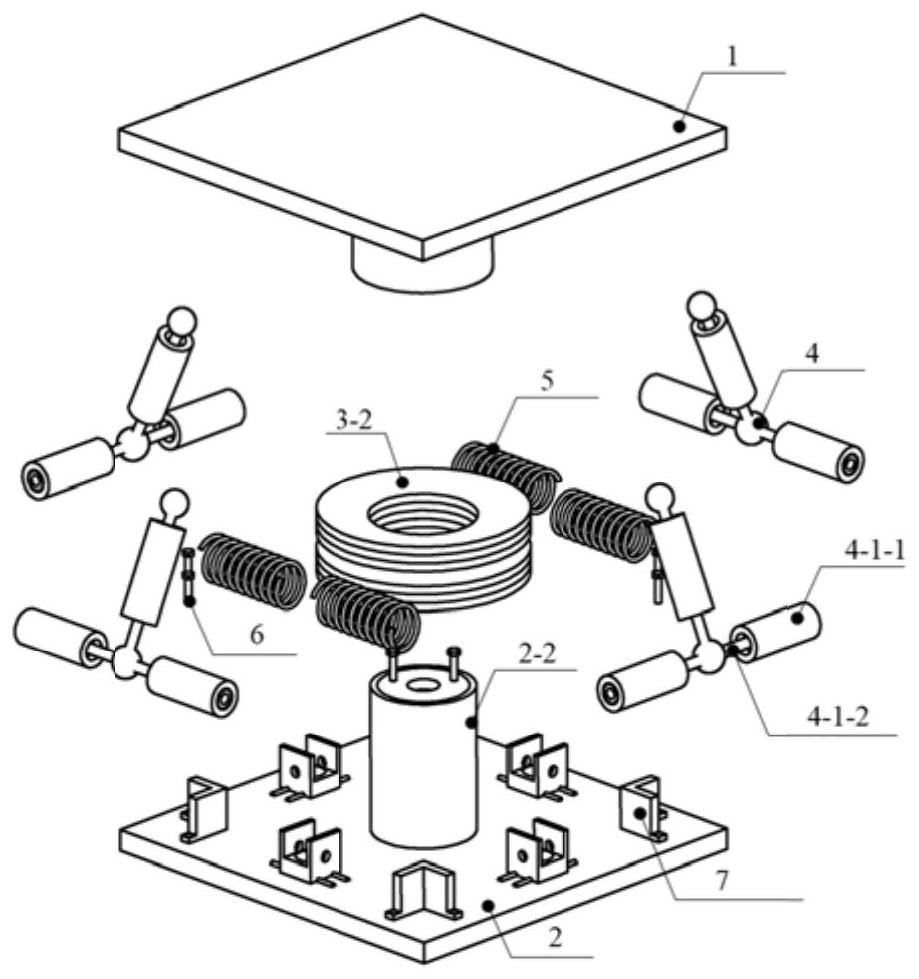

[0099] In this embodiment, the horizontal shock-absorbing part 4 is replaced by a single-tube compression form, and the slide rail 2-4, the support base 2-5, the first ball joint 4-3 and the The above-mentioned spiral steel spring 5; the second spherical hinge 4-4 and the reserved connecting piece 1-4 are all replaced by slide grooves and connected by bolts, which provides a certain level and vertical support for the device while ensuring effective displacement transmission. to the deformation space, such as Figure 6 , Figure 7 and Figure 8 shown.

[0100] In the working method of the device of this embodiment, the working method of the device to bear the vertical force is the same as that of Embodiment 1, the difference is that when it is vibrated in the horizontal direction,

[0101] When the device is subjected to a certain horizontal earthquake action, the upper end cover 1 drives the horizontally arranged cylindrical damping unit 4-1 through the connecting arm to ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com