Plate-type ballastless track multi-dimensional vibration isolation and reduction device and vibration reduction method thereof

A slab-type ballastless track and partition reduction technology, which is applied to tracks, roads, buildings, etc., can solve the problems of large vertical displacement of the track, high cost, and great impact on the safety of high-speed rail, so as to improve energy consumption, facilitate maintenance and Effect of replacement, good vibration isolation and energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

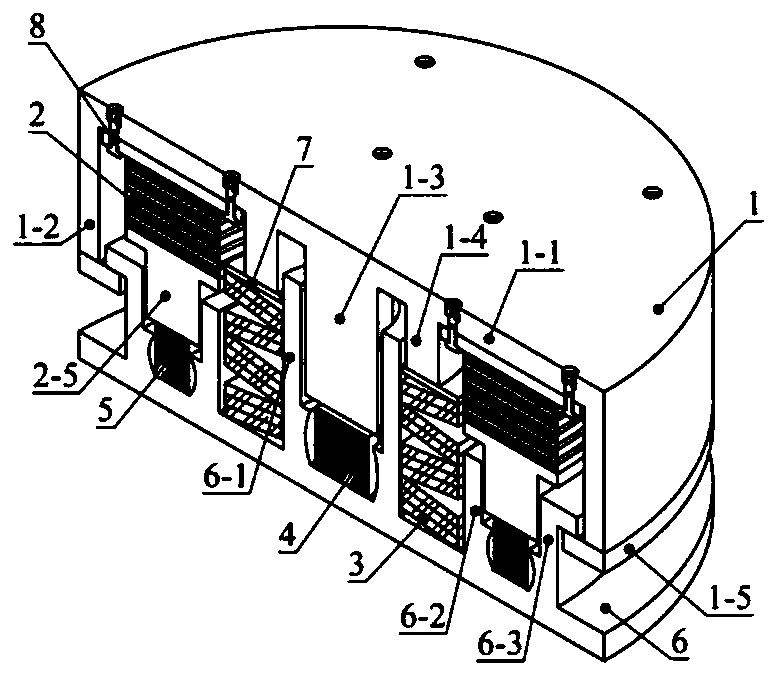

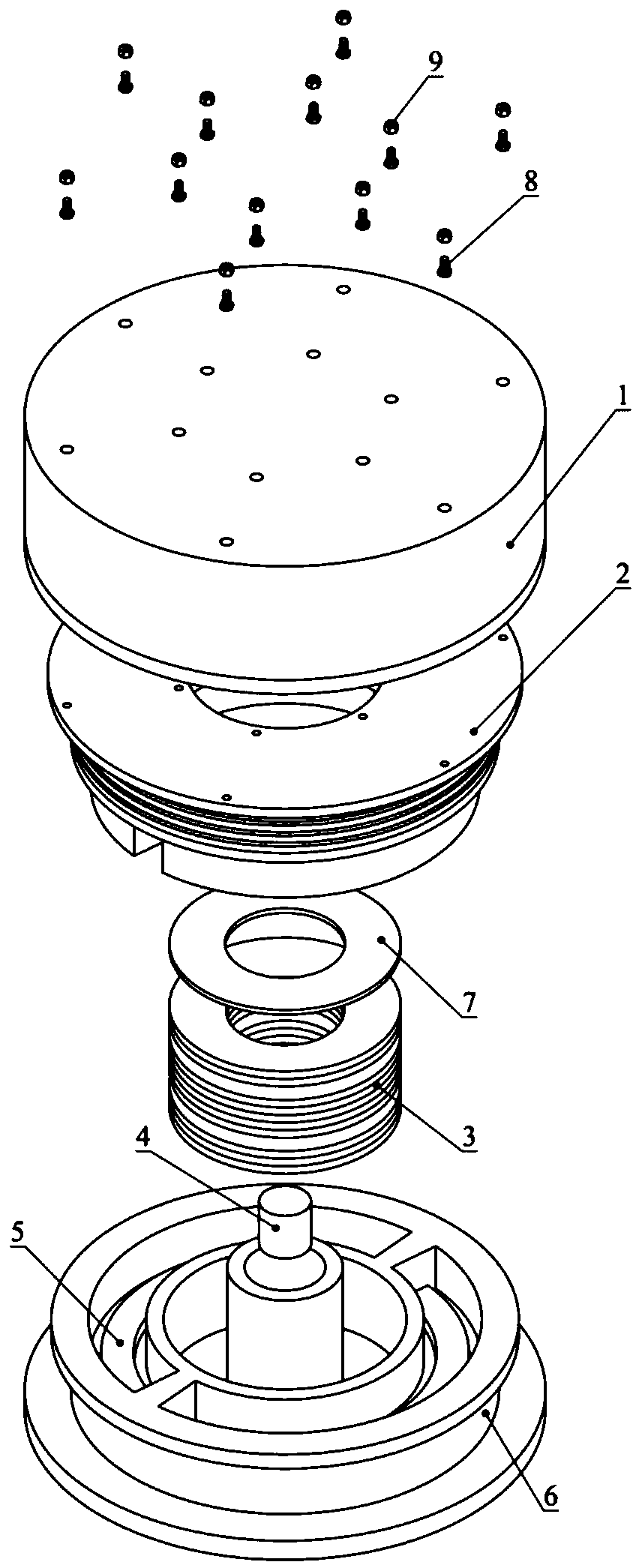

[0050] Such as Figure 1 to Figure 3 As shown, what the present invention describes is a multi-dimensional vibration isolation device for a plate-type ballastless track, which consists of an upper end cover 1, a ring-shaped vibration-damping pad 2, a pre-pressed disc spring group 3, an inner viscoelastic material block 4, an outer The viscoelastic material block 5 and the base 6 are composed of six major parts. The inner viscoelastic material block 4 , the disc spring group 3 and the outer viscoelastic material block 5 are placed from the center of the base 6 to the periphery in order to play the role of damping vibration in the vertical direction. The ring-shaped damping pad 2 is connected with the upper end cover 1 through bolts 8 and nuts 9 to play a role of horizontal vibration damping.

[0051] Such as figure 1 and Figure 4 As shown, the upper end cover 1 includes a top plate 1-1, an upper outer cylinder 1-2, a central pressing shaft 1-3, a first pressing cylinder 1-4...

example 1

[0059] Example 1 of the present invention The working method of a multi-dimensional insulation and damping device for plate-type ballastless track is:

[0060] The upper end cover 1 is used to support the slab ballastless track, the base 6 is fixed on the ballastless track base, and the device is first compressed by a large value during installation;

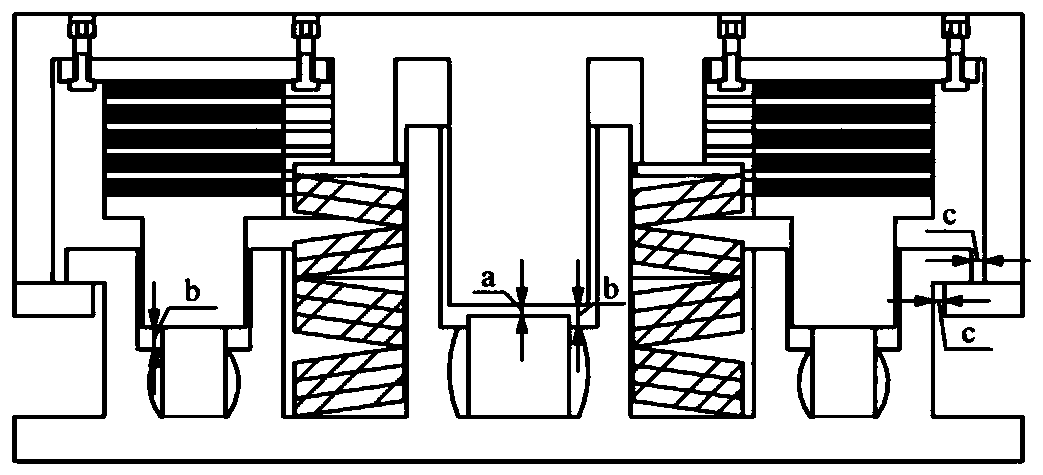

[0061] When there is no vehicle load, under the action of static loads such as slab ballastless tracks, rails and fasteners, the compressed disc spring group 3 recovers and deforms, and the upper end cover 1 moves upward through the first pressure cylinder 1-4 until it reaches the ring shape. The top surface of the inner bump 1-5 is in contact with the bottom surface of the outer bump on the top of the lower outer cylinder 6-3, and there is a first vertical separation distance a between the bottom surface of the central pressing shaft 1-3 and the top surface of the inner viscoelastic material block 4, At the same time, the secon...

Embodiment 2

[0068] In this embodiment, the disc spring group 3 is replaced by a paired and superimposed form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com