Multi-dimensional vibration isolation device and vibration isolation method for slab ballastless track

A slab-type ballastless track and isolation technology, applied in tracks, roads, buildings, etc., can solve the problems of large vertical displacement of the track, great impact on the safety of high-speed rail, and high construction cost, and achieve improved energy consumption and good vibration isolation performance. and energy consumption, easy maintenance and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

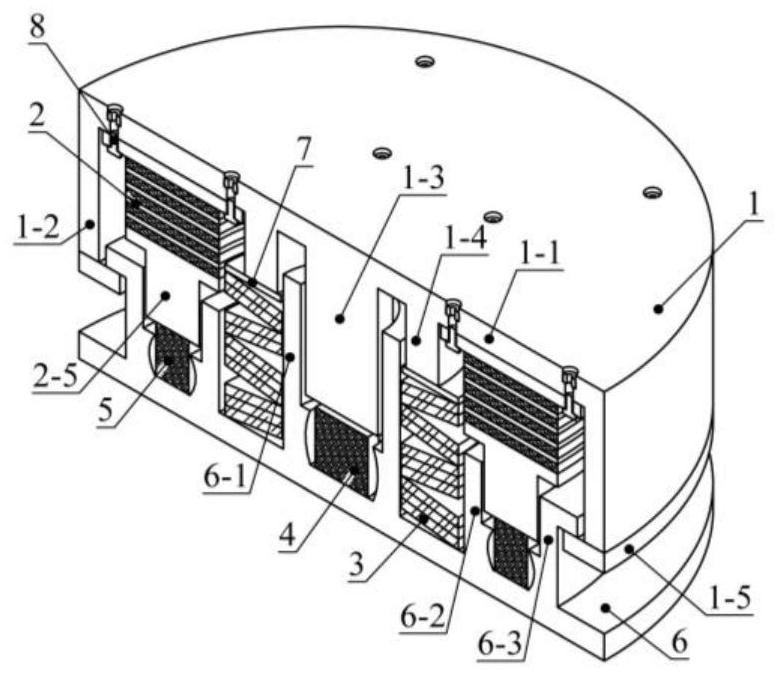

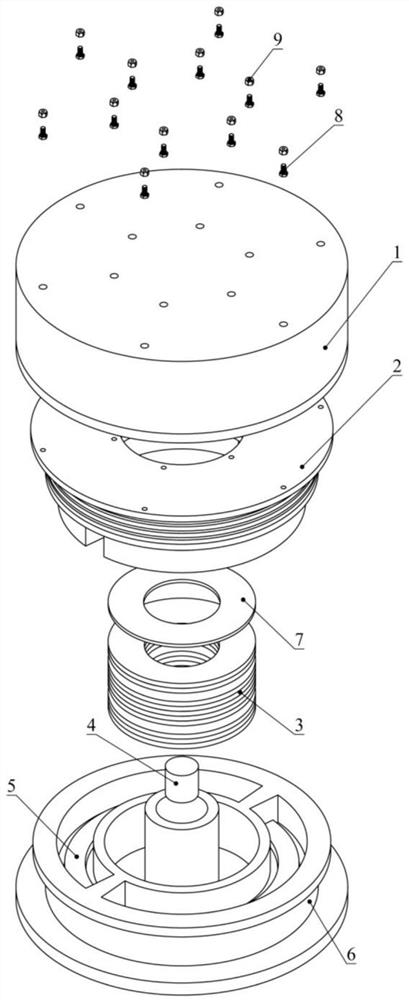

[0050] Such as Figure 1 to Figure 3 As shown, what the present invention describes is a multi-dimensional vibration isolation device for a plate-type ballastless track, which consists of an upper end cover 1, a ring-shaped vibration-damping pad 2, a pre-pressed disc spring group 3, an inner viscoelastic material block 4, an outer The viscoelastic material block 5 and the base 6 are composed of six major parts. The inner viscoelastic material block 4 , the disc spring group 3 and the outer viscoelastic material block 5 are placed from the center of the base 6 to the periphery in order to play the role of damping vibration in the vertical direction. The ring-shaped damping pad 2 is connected with the upper end cover 1 through bolts 8 and nuts 9 to play a role of horizontal vibration damping.

[0051] Such as figure 1 and Figure 4 As shown, the upper end cover 1 includes a top plate 1-1, an upper outer cylinder 1-2, a central pressing shaft 1-3, a first pressing cylinder 1-4...

example 1

[0059] Example 1 of the present invention The working method of a multi-dimensional insulation and damping device for plate-type ballastless track is:

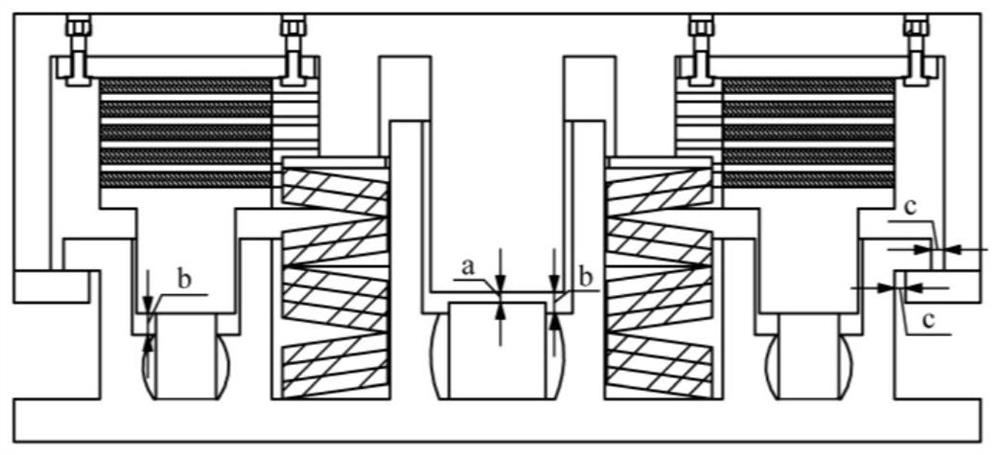

[0060] The upper end cover 1 is used to support the slab ballastless track, the base 6 is fixed on the ballastless track base, and the device is first compressed by a large value during installation;

[0061] When there is no vehicle load, under the action of static loads such as slab ballastless tracks, rails and fasteners, the compressed disc spring group 3 recovers and deforms, and the upper end cover 1 moves upward through the first pressure cylinder 1-4 until it reaches the ring shape. The top surface of the inner bump 1-5 is in contact with the bottom surface of the outer bump on the top of the lower outer cylinder 6-3, and there is a first vertical separation distance a between the bottom surface of the central pressing shaft 1-3 and the top surface of the inner viscoelastic material block 4, At the same time, the secon...

Embodiment 2

[0068] In this embodiment, the disc spring group 3 is replaced by a paired and superimposed form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com