Steel rail vibration damping noise reduction method for self-absorption composite magnetic damping plate

A technology for magnetic damping, vibration reduction and noise reduction, applied in tracks, roads, buildings, etc., can solve the problems of complex production process or installation process of rail damping plates, difficult detection and control of application quality, and inability to large-scale practical application, etc. Good vibration and noise reduction effect, small effect of temperature change, and wide vibration frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

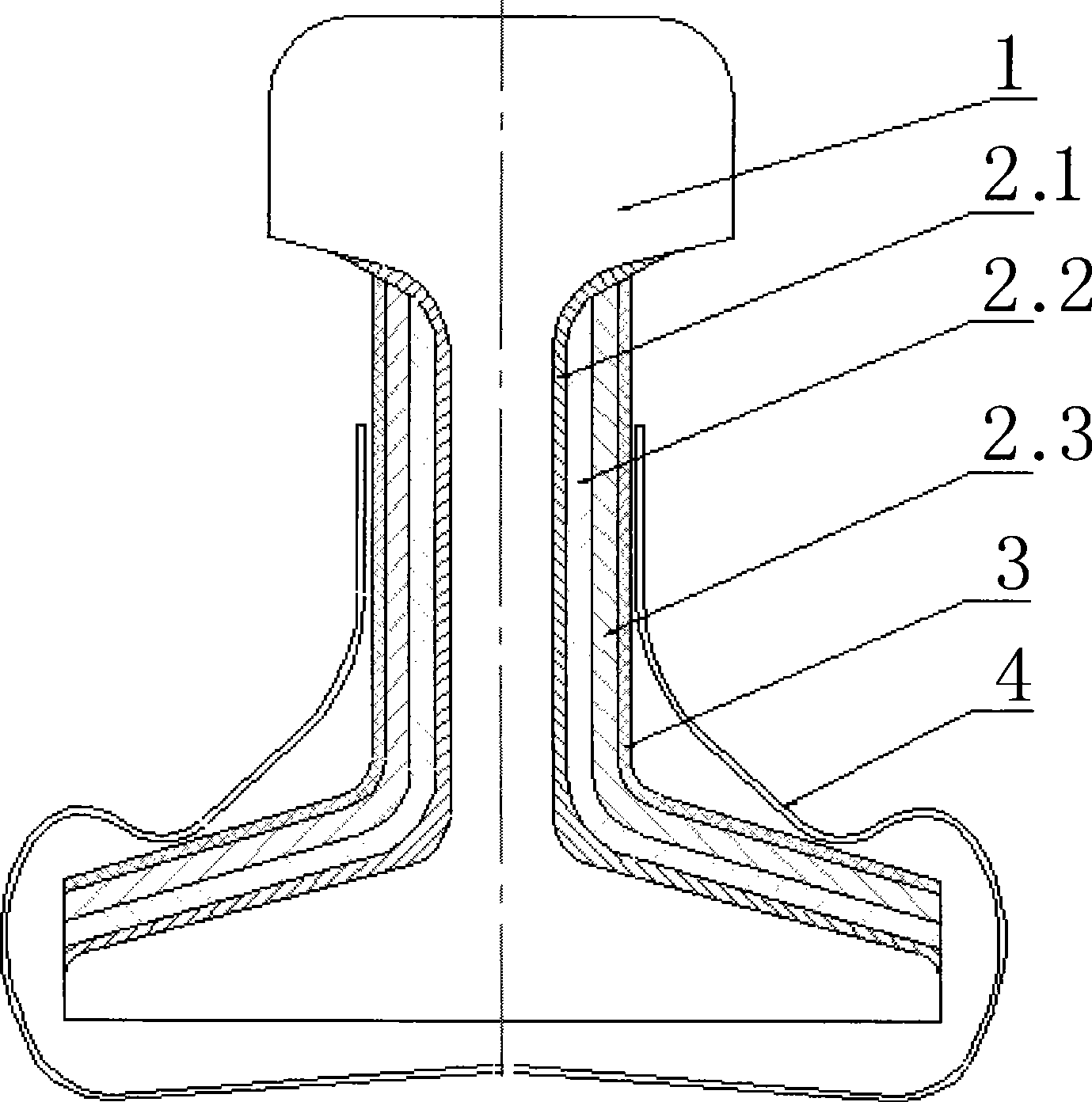

[0018] figure 1 The combined magnetic damping plate 2 is composed of the inner magnetic damping plate 2.1, the magnetic damping plate 2.2 and the outer magnetic damping plate 2.3, and its materials are all magnetic damping polymer flexible materials. In order to clearly show the difference in the section of the damping plate of each layer, in figure 1 The section lines given in are also different, but this does not affect the consistency of the material, the difference is that the area used by each layer of damping plate will be different.

[0019] for this through figure 1 It can be clearly seen that the method that the self-priming combined magnetic damping plate of the present invention is used for rail vibration and noise reduction is to symmetrically arrange the combined magnetic damping plate 2 at the rail waist and the rail foot of the rail 1, and outside the combined magnetic damping plate 2 Constraint metal plates 3 are arranged symmetrically in layers, and are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com