Vibration damping protection tunnel with constrained damping structure and construction method of tunnel

A technology of constrained damping and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve hidden dangers in tunnel operation safety, affect engineering quality and other issues, solve waterproof and leakage problems, improve durability, and ensure driving and personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

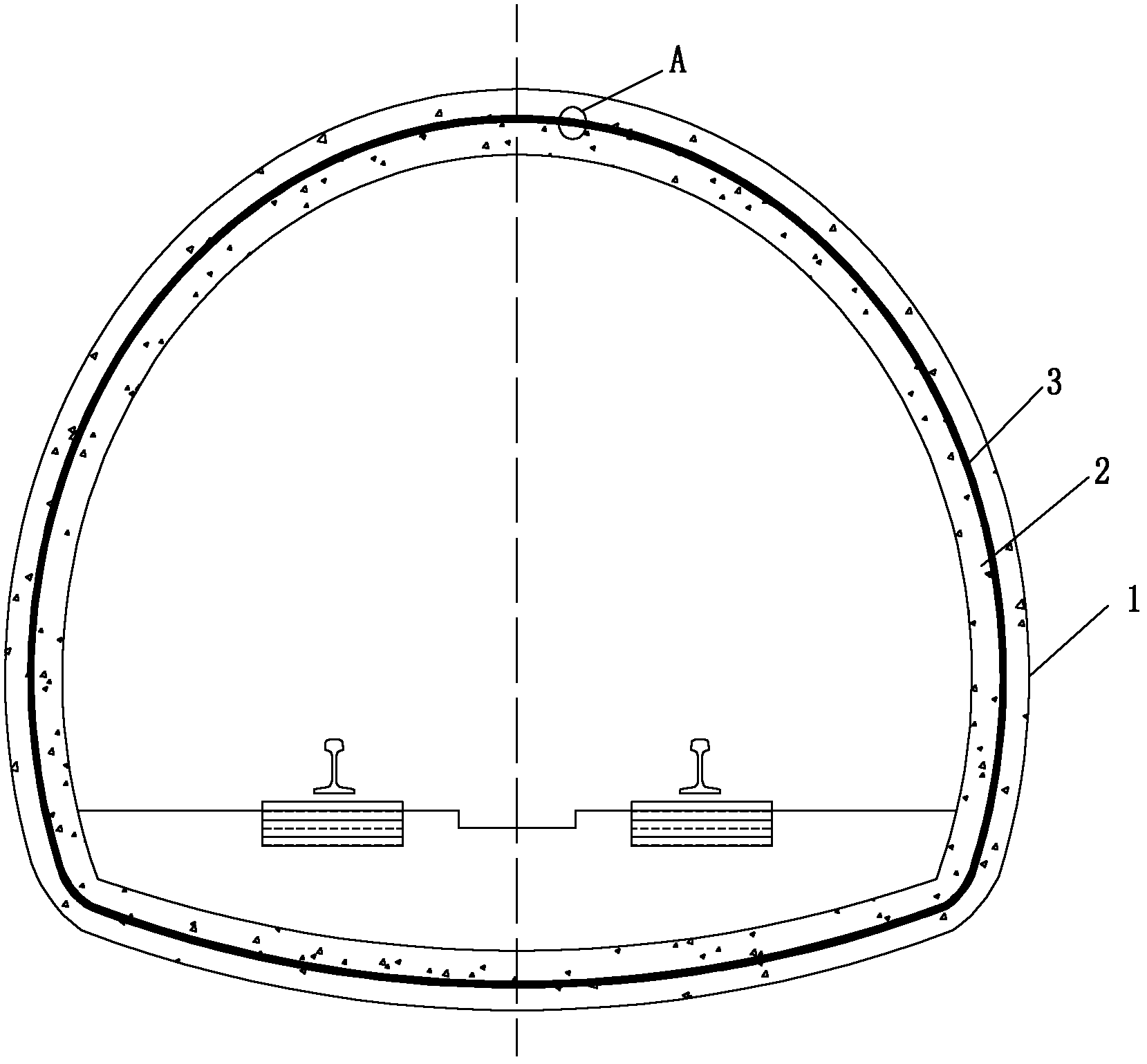

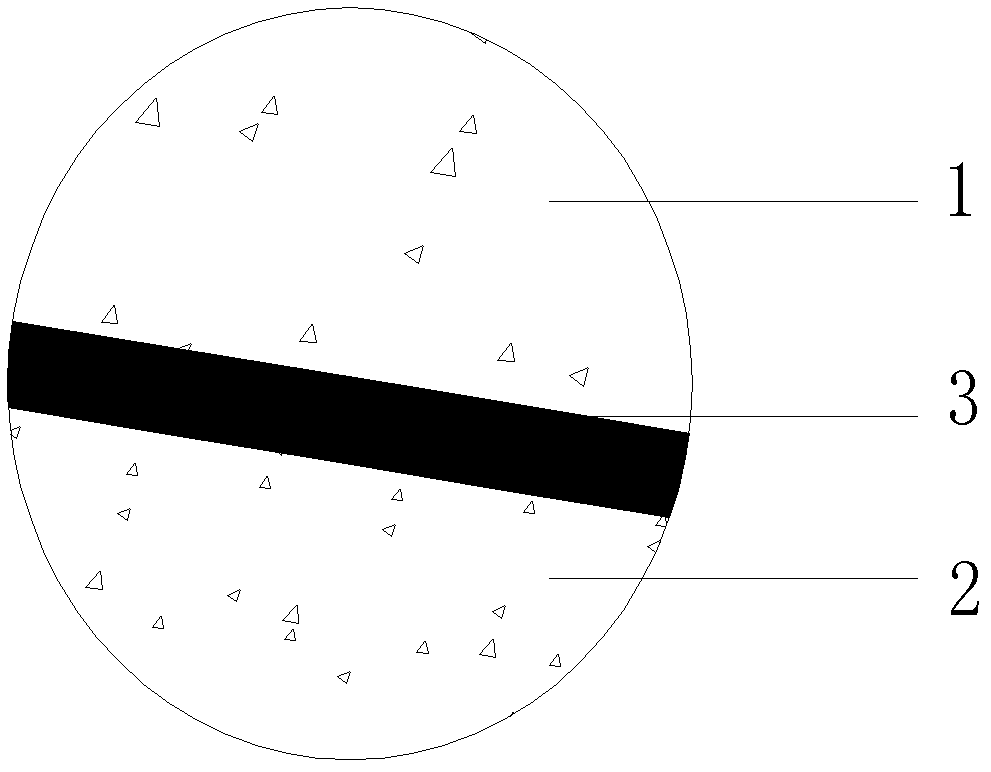

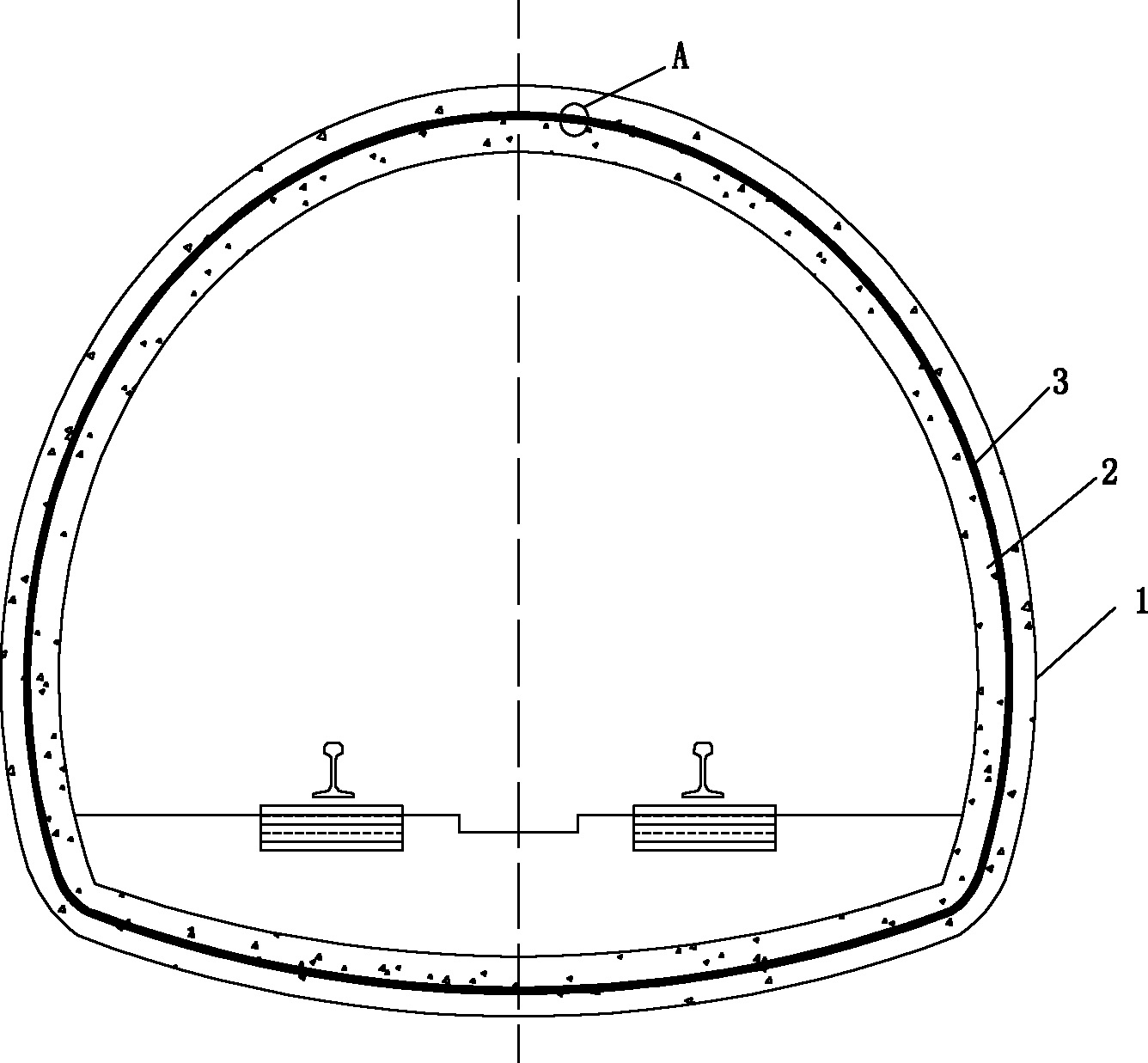

[0018] Such as figure 1 , figure 2 As shown, the concrete layer 1 for the primary support of the tunnel is included, the viscoelastic damping layer 3 is laid on the concrete layer 1 for the initial support of the tunnel, and the secondary lining concrete layer 2 is provided on the surface of the viscoelastic damping layer 3 .

[0019] The thickness ratio of the viscoelastic damping layer 3 to the secondary lining concrete layer 2 is 1:15. The viscoelastic damping material used in the viscoelastic damping layer 3 has a stiffness modulus between 2-20 MPa, a temperature range of -10°C-50°C with a loss factor above 0.5, and a frequency range of 0-300Hz .

[0020] Method steps of the present invention are as follows:

[0021] (1) First of all, after the initial support of the tunnel is completed, the surface treatment of the concrete layer 1 of the initial support of the tunnel is carried out. The specific method is: firstly, the concrete surface is mechanically treated to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com