Smoke discharge equipment and method for substation antenna soldering

A base station antenna and soldering technology, which is applied to welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of decreased cooling effect in the production workshop space, increased air conditioning load, waste of resources, etc., to improve the efficiency and accuracy of the soldering iron, Reduce air-conditioning loss and ensure air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

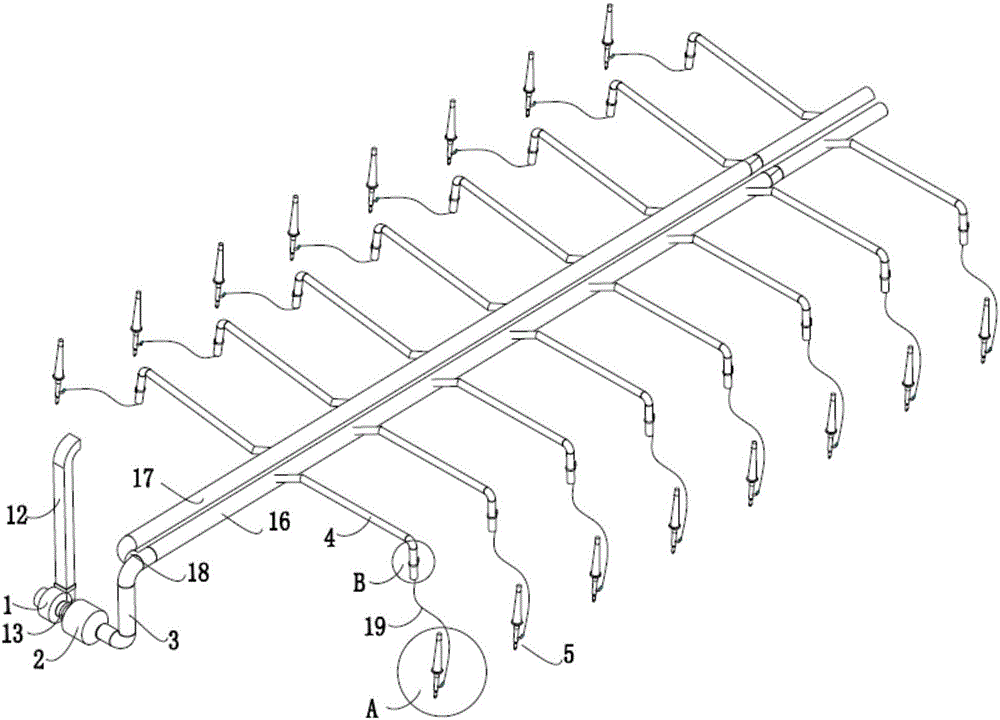

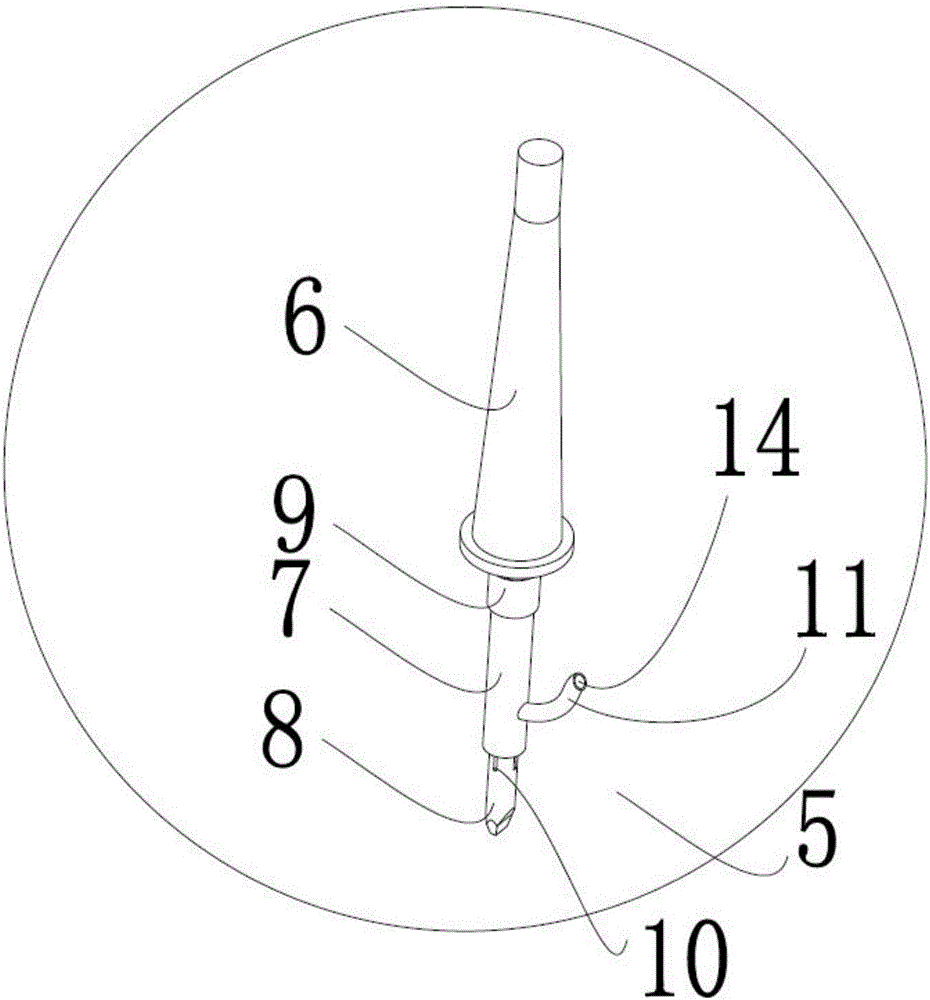

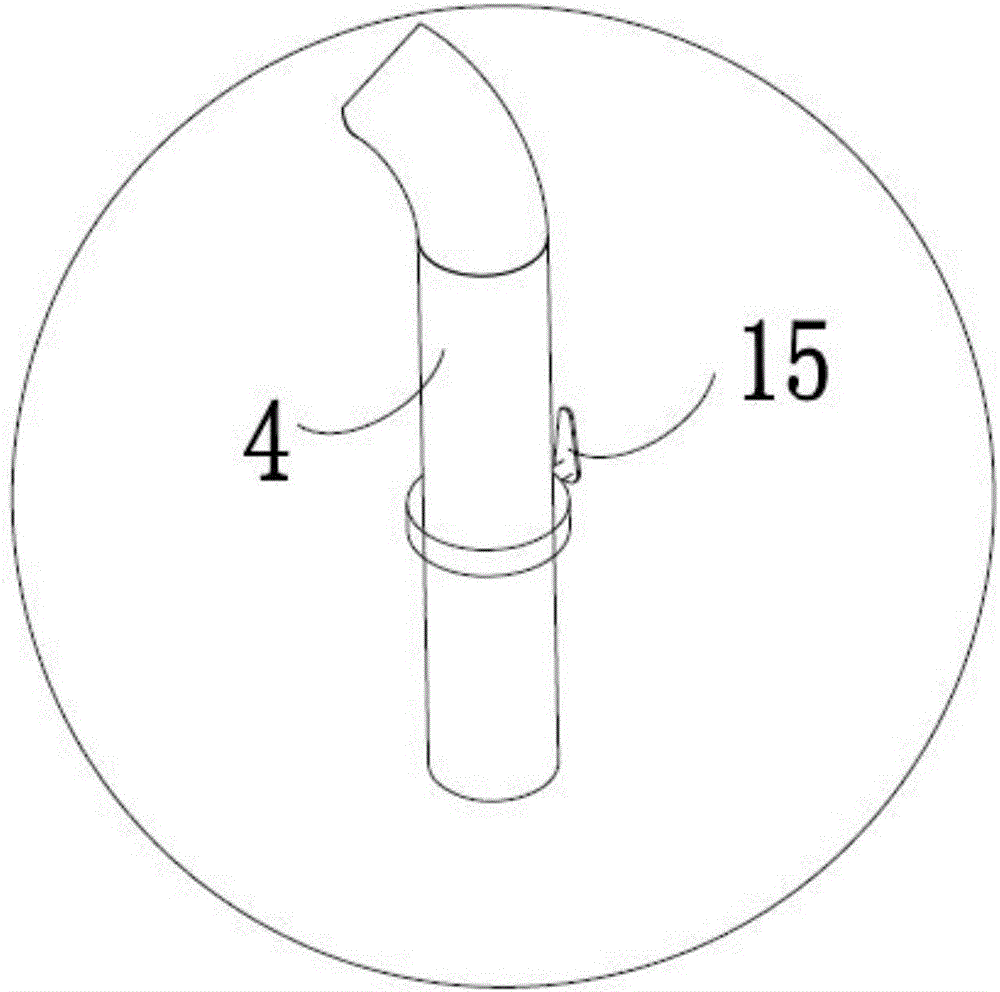

[0026] Example: such as Figure 1 to Figure 3 As shown, the present invention is a base station antenna soldering smoke exhaust equipment, which includes a smoke exhaust machine 1, a filter 2, a smoking main pipe 3 and several branch pipes 4 connected in sequence, and the branch pipes 4 are connected with a soldering iron smoking pipe. The soldering iron smoker 5 includes a soldering iron handle 6, a smoking support 7 and a soldering iron head 8 sequentially connected from top to bottom, the lower end of the soldering iron handle 6 is provided with a fixed joint 9, and the lower end of the fixed joint 9 is connected to the The upper end of the smoking support 7 is connected, and the lower end of the smoking support 7 is connected to the upper end of the soldering iron tip 8. The smoking support 7 is a cylindrical structure, and a number of smoke collectors are arranged on the upper wall of the soldering iron tip 8. A hole 10 is provided in the smoking support 7 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com