Viscous damper

A viscous damper and damper technology, applied in the direction of solid shock absorbers, etc., can solve the problems of structural sloshing, small initial stiffness of the damper, and low surface accuracy, so as to increase the initial stiffness, avoid liquid leakage, and reduce Effect of Surface Roughness Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

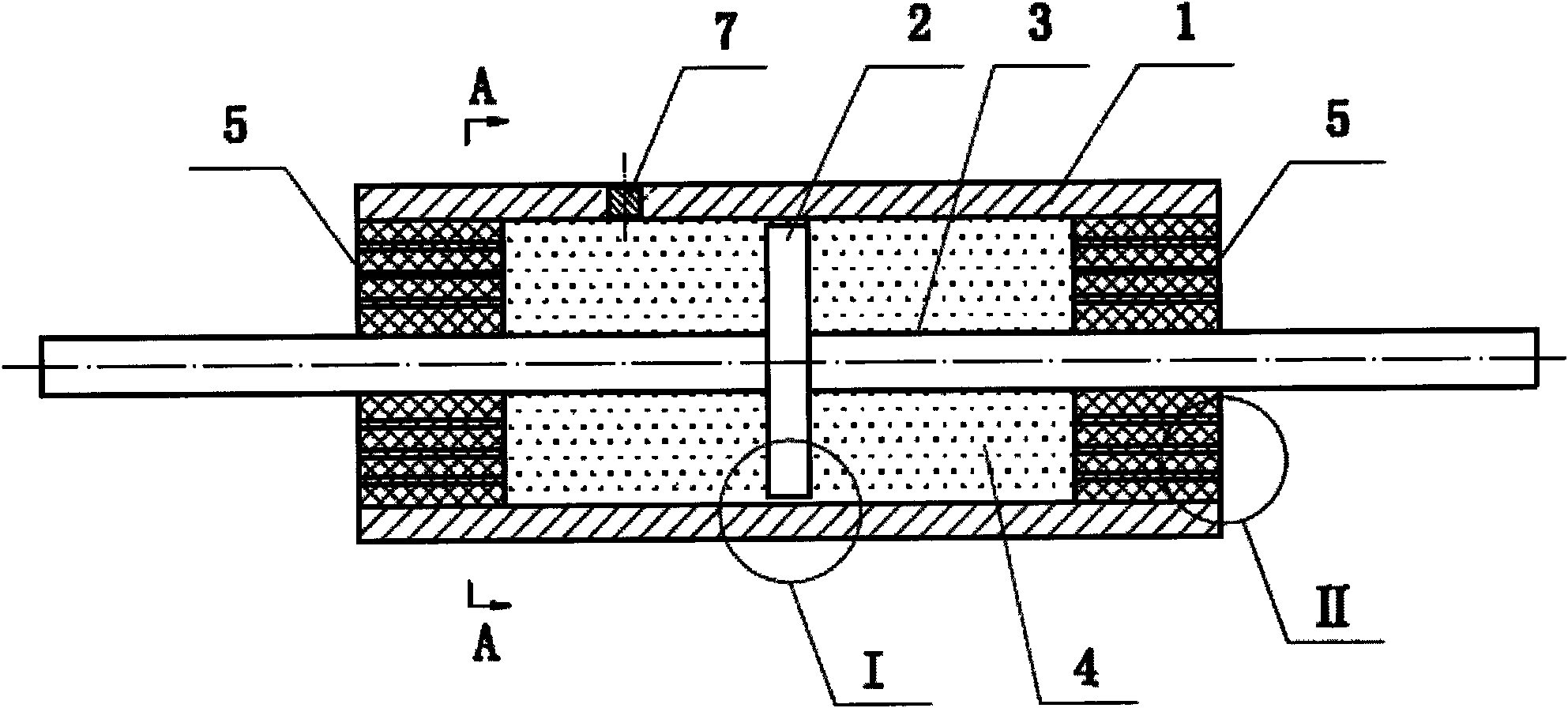

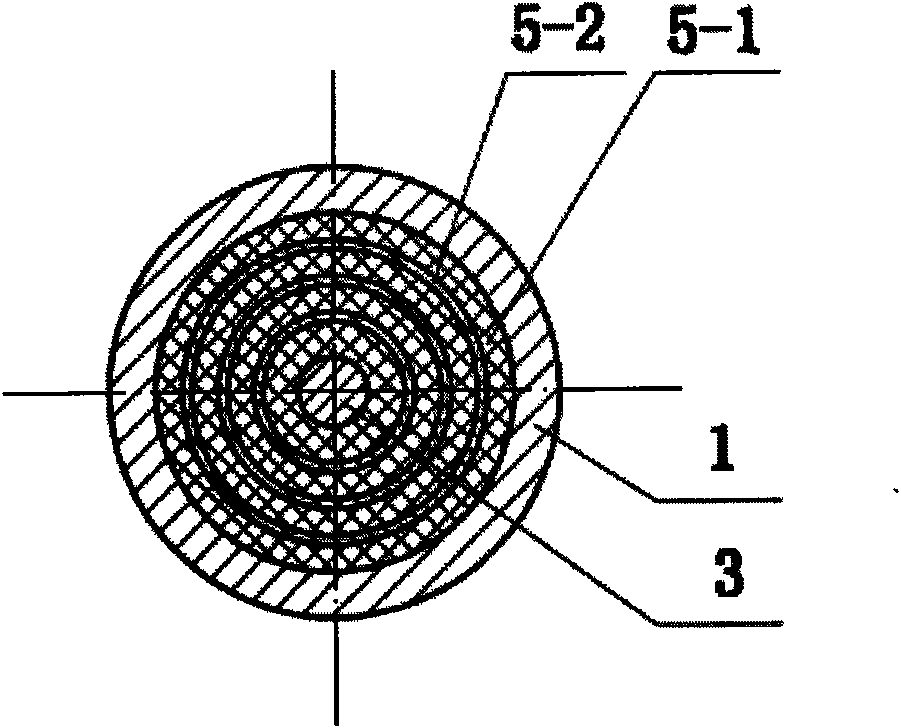

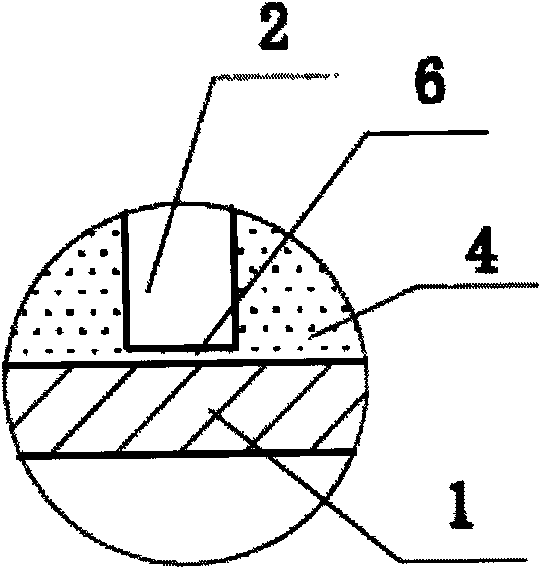

[0021] see Figure 1~4 , The viscous damper of this embodiment consists of a cylindrical cylinder 1, a piston 2, a piston rod 3, an elastic body 5 and a damping medium 4. Wherein, the center of the piston 2 is provided with a through hole, and the piston rod 3 passes through the through hole and is welded integrally with it; a damping gap 6 is provided between the radial edge of the piston 2 and the cylinder body 1 (see image 3 ); the elastic body 5 is arranged on the two ends of the cylinder body 1 (equivalent to the end cap), and is integrated with the cylinder body 1 and the piston rod 3 through high-temperature vulcanization; the elastic body 5 is composed of an annular rubber material layer 5-1 It is formed by high-temperature vulcanization alternately stacked with annular thin steel plate layers 5-2 (see Figure 4 ), the ratio of its diameter to width is 2 to 4; the cylinder body 1 is provided with a perfusion hole, and the damping material 4 is poured into the inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com