Water-based viscous-elastic damping sound-insulation adhesive

A viscoelastic and adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of wall thickening, complicated installation, high cost, and achieve strong adhesion, human body and environment. Friendly, high damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

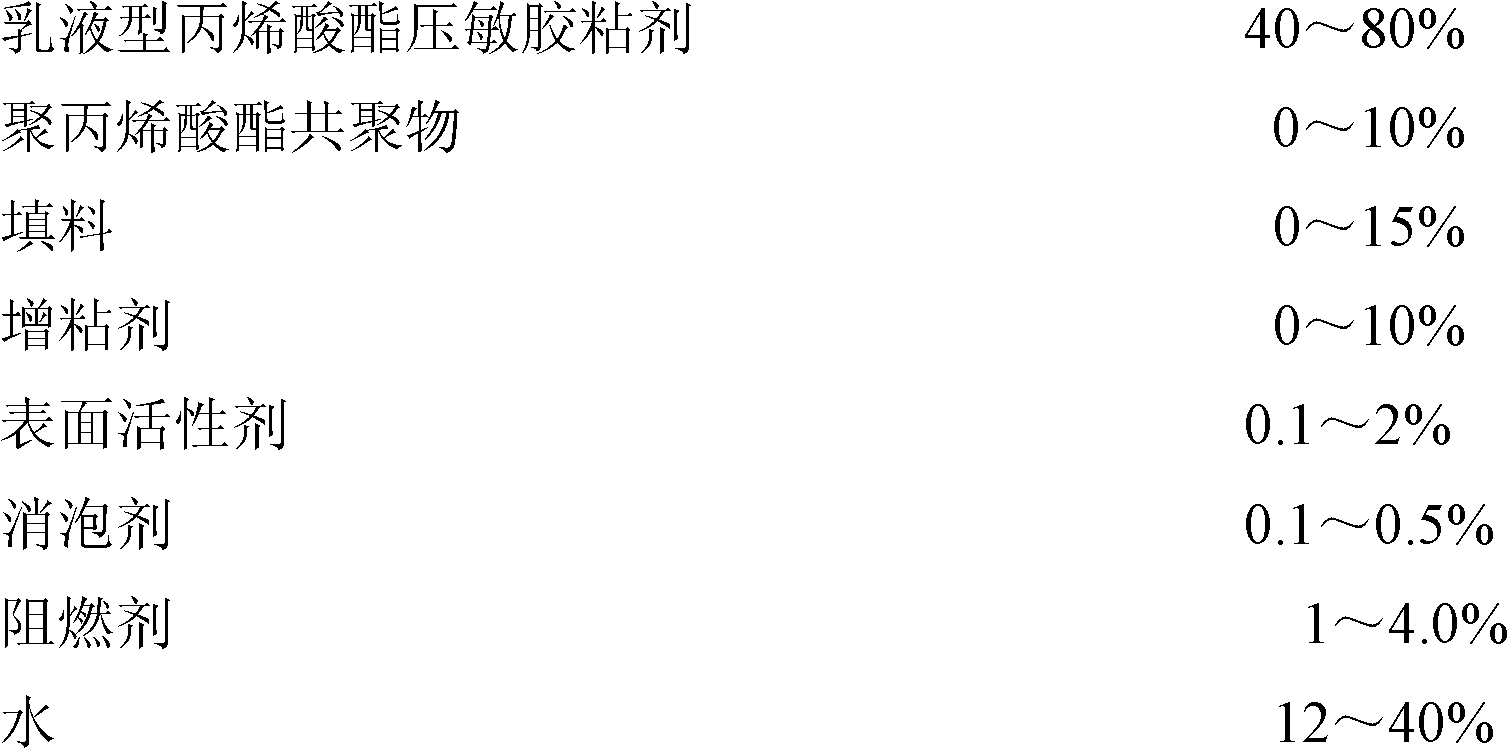

[0029] Weigh each component raw material according to the following composition formula:

[0030]

[0031] The preparation process is as follows:

[0032] a) Forcibly blending the emulsion-type acrylate pressure-sensitive adhesive with the polyacrylate copolymer for 15 to 60 minutes to prepare emulsion A;

[0033] b) uniformly add the filler into the water, stir for 20-50 minutes, add a thickener, a surfactant, a defoamer, a flame retardant and a bactericide, stir for 10-30 minutes to mix evenly, and prepare slurry B;

[0034] c) Add the prepared emulsion A into the slurry B, and stir for 15-40 minutes to obtain.

[0035] According to the ASTM-E-756-98 standard, the water-based viscoelastic damping and sound-insulating adhesive described in this embodiment maintains a damping platform with a damping value above 0.9 between 7°C and 132°C.

[0036] According to GB-T2791-1995, the T-peel strength of the water-based viscoelastic damping sound-insulating adhesive described in ...

Embodiment 2

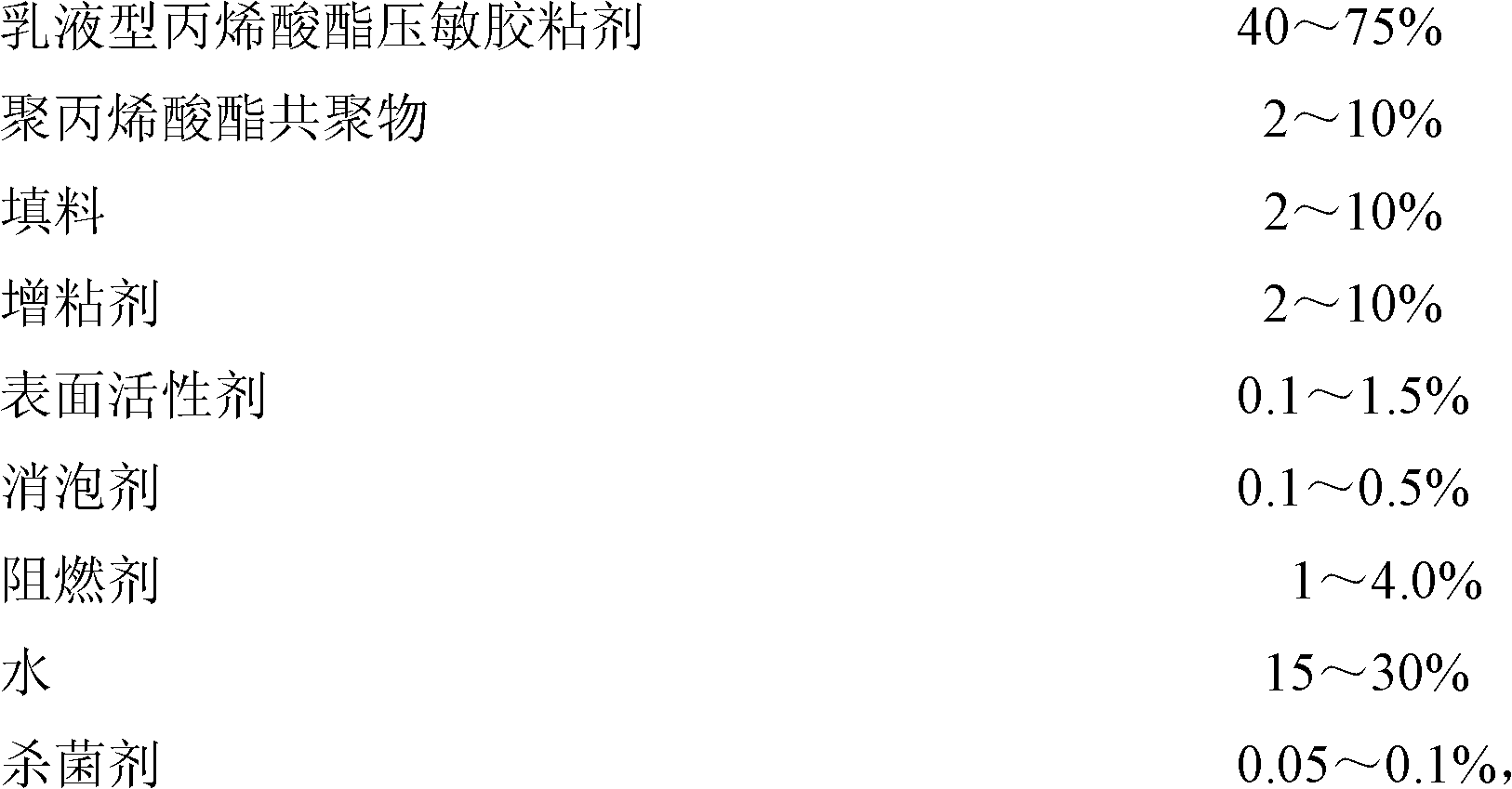

[0038] Weigh each component raw material according to the following composition formula:

[0039]

[0040] The preparation process is the same as described in Example 1.

[0041] According to the ASTM-E-756-98 standard, the water-based viscoelastic damping and sound-insulating adhesive described in this embodiment maintains a damping platform with a damping value above 0.9 at a temperature between -22°C and 83°C.

[0042] According to GB-T2791-1995, the T-peel strength of the water-based viscoelastic damping and sound-insulating adhesive described in this embodiment is 53 N / cm.

Embodiment 3

[0044] Weigh each component raw material according to the following composition formula:

[0045]

[0046] The preparation process is the same as described in Example 1.

[0047] According to the ASTM-E-756-98 standard, the water-based viscoelastic damping and sound-insulating adhesive described in this embodiment maintains a damping platform with a damping value above 0.9 between -9°C and 102°C.

[0048] According to GB-T2791-1995, the T-peel strength of the water-based viscoelastic damping sound-insulating adhesive described in this embodiment is 46.8 N / cm.

[0049] In summary, it can be seen that the water-based viscoelastic damping and sound-insulating adhesive of the present invention is an environmentally friendly adhesive, non-toxic and harmless, friendly to the human body and the environment, and has high damping value, wide temperature range, strong cohesiveness, and a damping value The damping platform above 100°C in the temperature range above 0.9, T-peel streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com