Manufacturing process of composite material laying tape of embedded co-curing continuous presoaking damping film

A composite material and prepreg technology, applied in the field of materials, can solve the problems of low degree of automation, polluting the environment, volatile gasoline, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

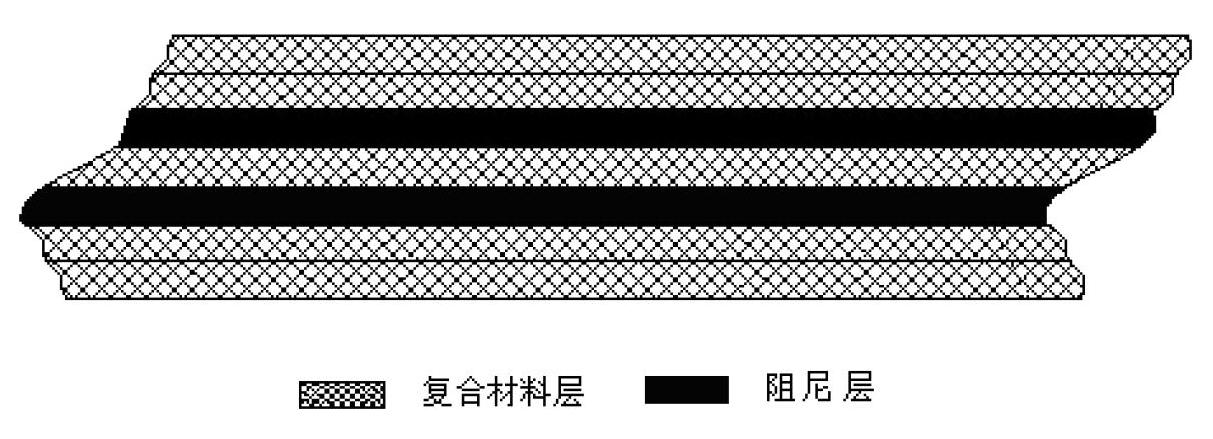

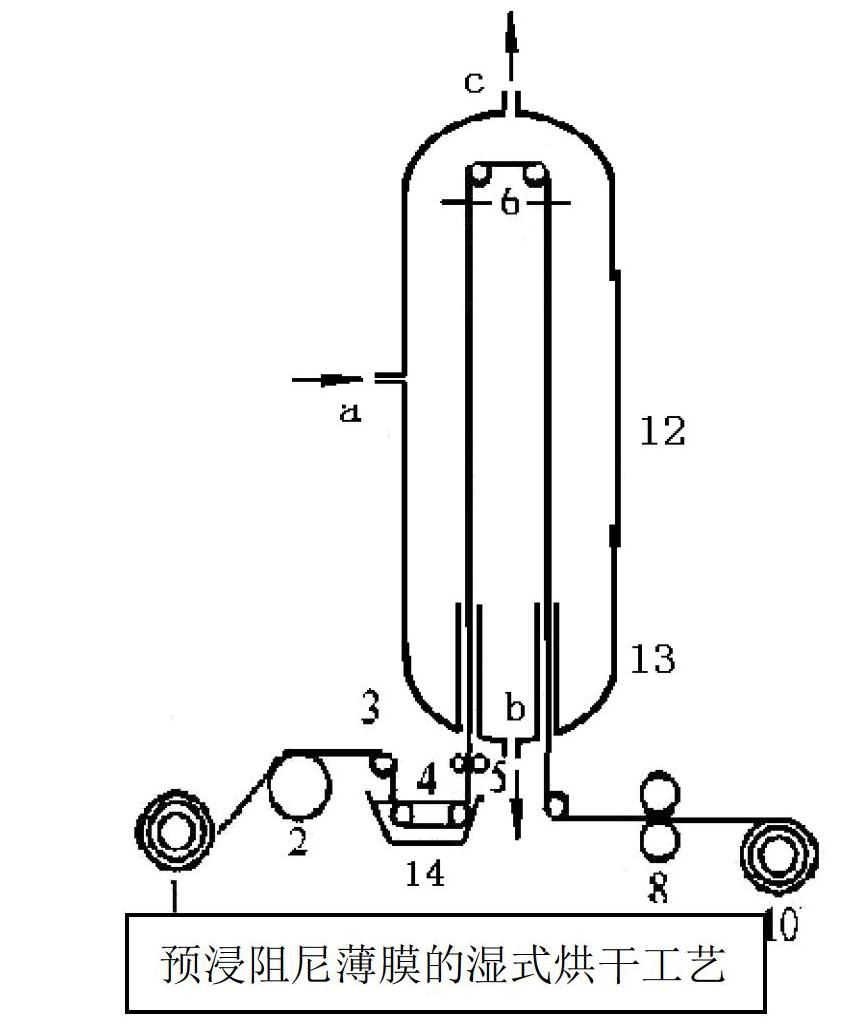

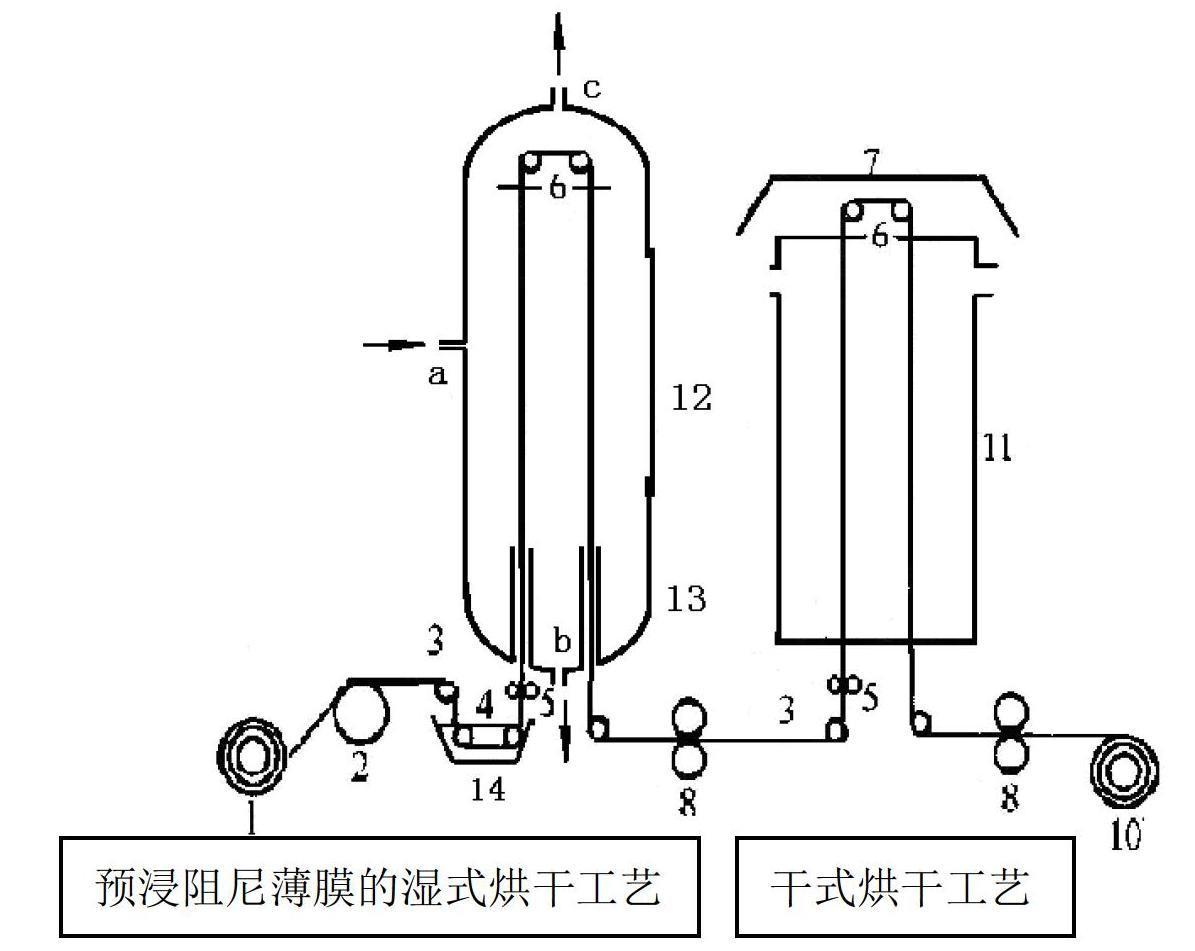

[0048]This process takes advantage of the designability of the mechanical properties of composite materials. The mixture of butyl rubber and chlorinated butyl rubber is selected as the main raw material and dissolved in an organic solvent (No. 120 gasoline) to make a viscoelastic damping material solution. The composite material prepreg with damping film is made by impregnation process, and the co-curing process is completed in the autoclave according to the curing parameter curve of different resins by taking advantage of the good adhesion of chlorobutyl rubber, so that the layers can be tightly bonded Combined together, the purpose of greatly improving the damping performance of the composite laminate structure is achieved without loss of component stiffness. The specific implementation method is:

[0049] 1. Mixing of raw rubber: form the raw rubber according to the viscoelastic material formula, and then mix the raw rubber. The feeding sequence used in the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com