Hydraulic braking system of large-tonnage electric fork-lift truck

A hydraulic braking and electric forklift technology, applied in the direction of brakes, braking transmissions, vehicle components, etc., can solve the problems of restricting oil sources and the number of oil pumps, and achieve the effects of accurate and convenient operation, high safety, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

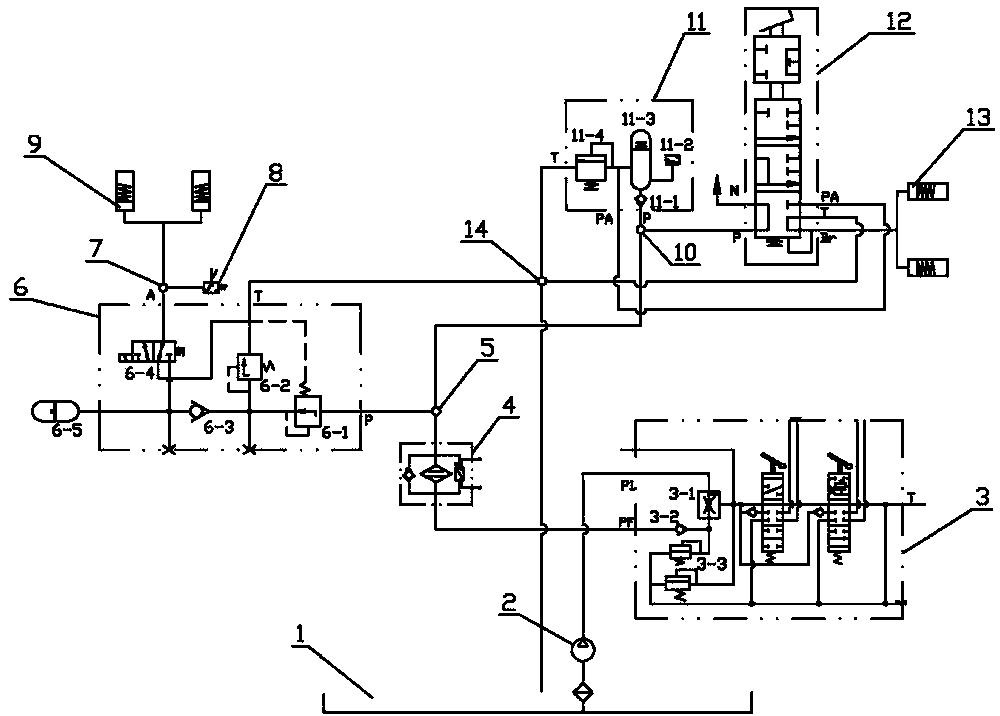

[0022] Such as figure 1 As shown, in this embodiment, the oil tank 1 and the oil pump 2 of the hydraulic working system are used to provide the service brake, the parking brake, and the oil source of the steering system. The oil outlet of the oil pump 2 is connected with the P1 port (oil inlet) on the oil inlet valve plate of the multi-way reversing valve 3 integrated with the monostable diverter valve. The PF port (oil outlet) of the multi-way reversing valve is connected to the oil inlet port of the pipeline filter 4. The pipeline filter filters the pressure oil to ensure the cleanliness of the pressure oil. There are bypass valves and differential pressure signaling devices. The oil outlet of the pipeline filter 4 is divided into two paths through the front tee 5, one path is connected with the P port (oil inlet) of the parking integrated valve 6, and the other path is divided into two paths through the rear tee 10. A port (oil outlet) on the parking integrated valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com