Automatic on-line width adjustment control system for continuous casting and process control method

A technology of control system and process control, applied in the field of automatic online width adjustment control system and process control, can solve the problems of low frequency of heat width adjustment of casting machines, system configuration and process methods are not disclosed, and avoid abnormal heat width adjustment, Effects of preventing quality control and production abnormalities and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

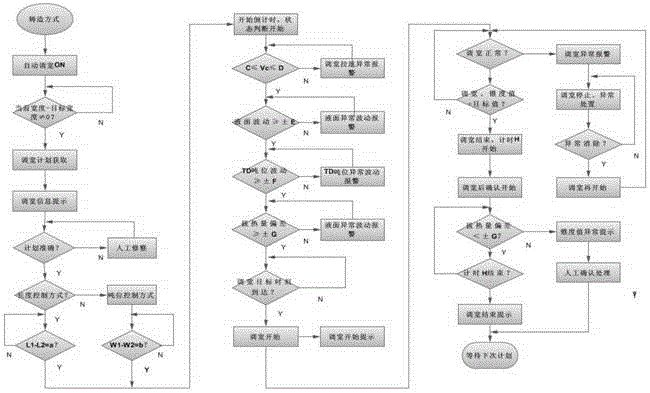

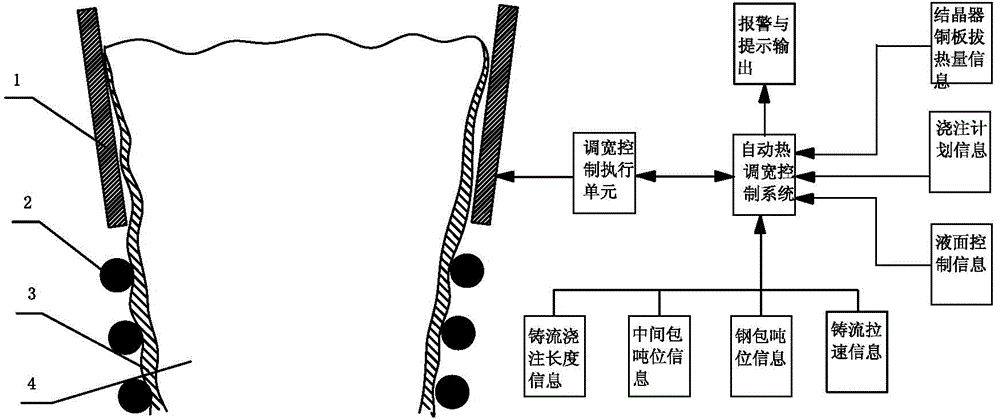

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Continuous casting thermal width adjustment is one of the links most prone to abnormalities in the slab continuous casting production process, including width adjustment setting errors, width adjustment omissions, abnormal working conditions before width adjustment, abnormal width adjustment process, and short width after width adjustment. Problems such as abnormal taper of the side copper plate are important factors affecting the quality control of casting slabs and production accident control, and are also the source of tedious confirmation work for operators, as well as a major obstacle to continuous casting automation and "unmanned" pouring.

[0034] In fact, modern casting machines with online thermal width adjustment function have relatively advanced on-site primary instrument information collection and computer control functions. Thermal wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com