Freight lift car frame device

A car frame and freight elevator technology, applied in the field of freight elevator car frame layout, can solve the problems of being concentrated on one side, unable to meet the strength requirements, and heavy car loads, etc., to achieve the effects of increased stability, simple processing, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

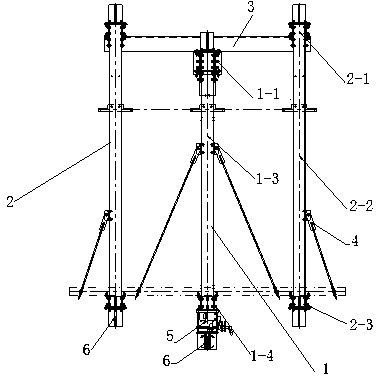

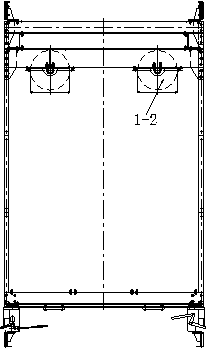

[0018] A freight elevator car frame device used for the load of a large-tonnage elevator, including a main car frame 1, an auxiliary car frame 2, a beam channel steel 3, and a tie rod assembly 4. The main car frame 1 includes a main upper beam assembly 1-1 , car top wheel assembly 1-2, main vertical beam assembly 1-3, main lower beam assembly 1-4, auxiliary car frame 2 includes auxiliary upper beam assembly 2-1, auxiliary vertical beam assembly 2-2, auxiliary lower beam assembly 2-3. The components of the main car frame 1 and the auxiliary car frame form an integral structural frame through bolts. The crossbeam channel steel 3 runs through the main car frame 1 and the auxiliary car frame 2. Both are provided with a brace screw assembly 4 .

[0019] The safety gear device 5 in the present invention is fixed on the main car frame 1 to prevent accidents when the elevator is running. The main car frame 1 is provided with guide shoes 6, which increases the stability of the elevato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com