Steel strand finished stay cable and manufacturing method thereof

A technology for steel strands and finished products, applied in the cable field, can solve the problems of high quality control requirements in the construction process, difficult processing, difficult to repair, etc., and achieves simple and fast anti-corrosion work, reduced processing difficulty, and shortened processing cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

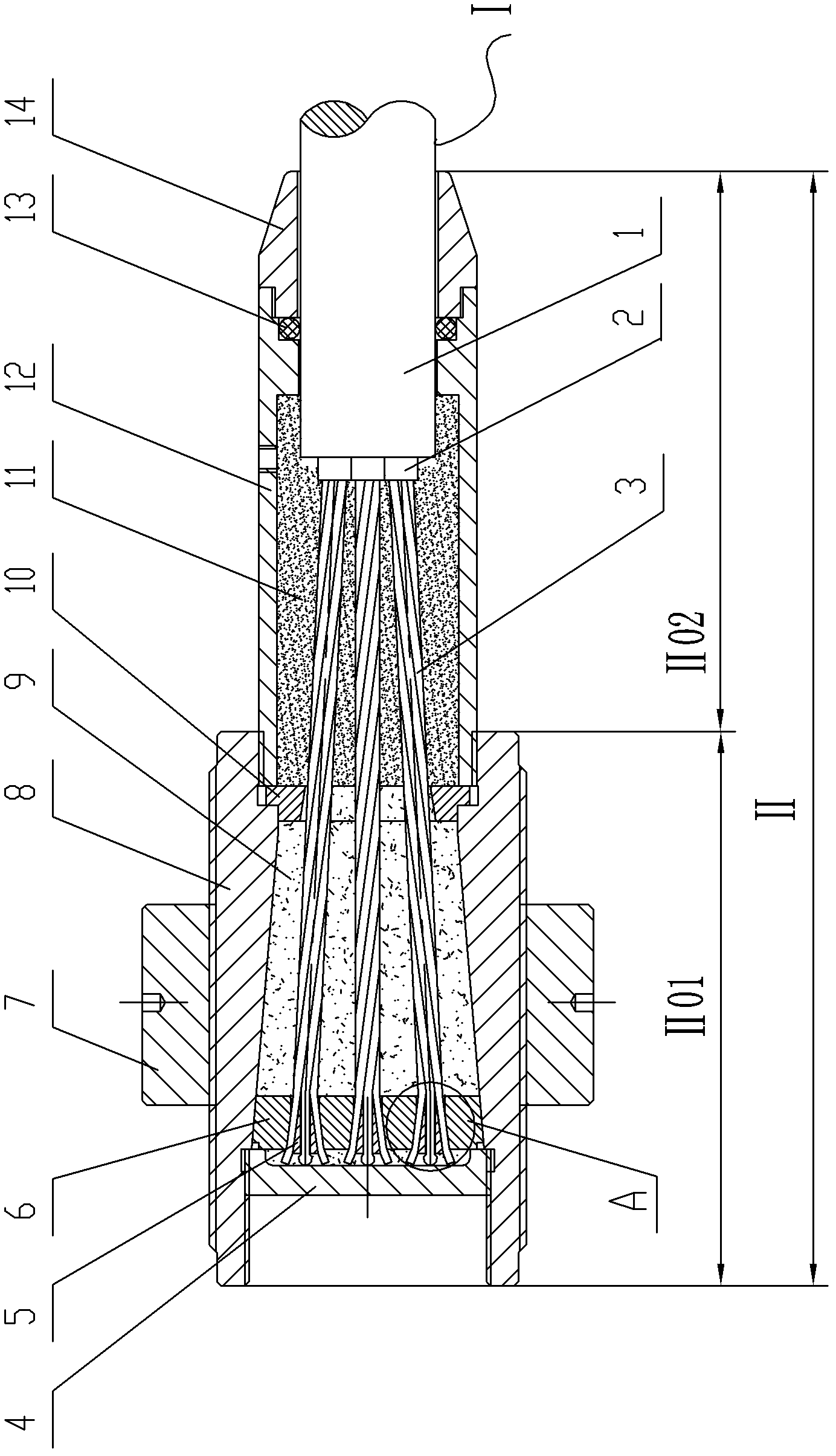

[0050] A steel strand finished cable composed of isolated anti-corrosion steel strands, including a cable body I and two anchor pieces II located at both ends of the cable body I, the cable body I is 7 single-strand steel strands 3 and An isolated anti-corrosion steel strand body composed of inner and outer PE sheaths; each anchor II includes anchor unit II01 and sealing unit II02 (see figure 1 );

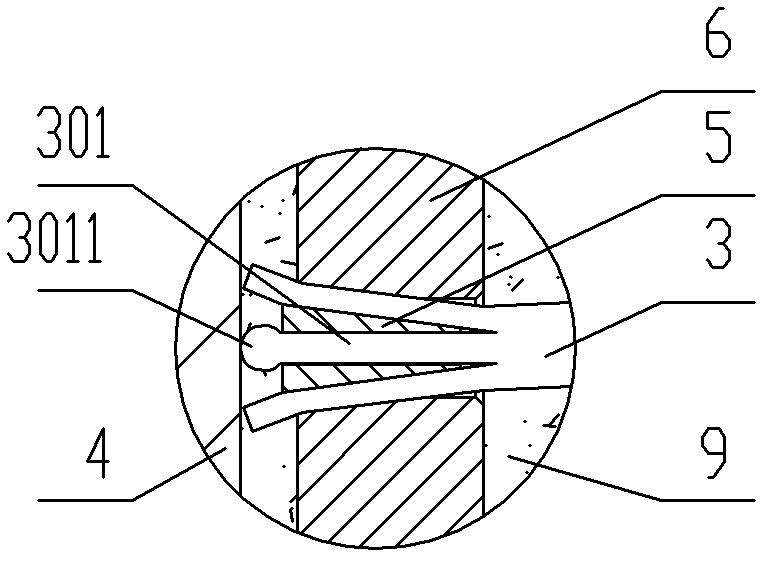

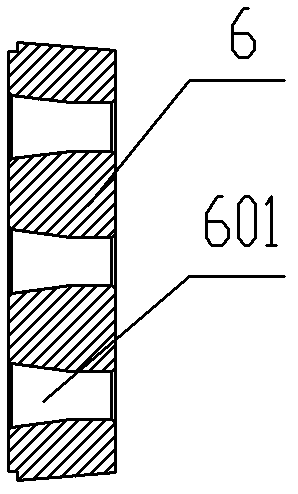

[0051] The anchoring unit II01 includes an end cap 4, a cone sleeve 5, an anchor plate 6, an anchor cup 8, an epoxy filler 9 and a restraint ring 10; the anchor plate 6 has a plurality of conical cones for anchoring a single-strand steel strand. Anchor holes 601, 7 single-strand steel strands 3 pass through the anchor cup 8, and each single-strand steel strand 3 penetrates into the corresponding tapered anchor holes 601 of the anchor plate 6, each single strand in the anchorage The steel strand 3 is twisted by 7 steel wires, and the structure of each single strand 3 in the anchor...

Embodiment 2

[0058] The manufacturing method of a steel strand finished cable described in the first embodiment. Its production process includes the following steps:

[0059] A. Remove a length of the sheath at one end of the cable body I that constitutes the finished cable of the steel strand, and clean up the surface of each single strand 3;

[0060] B. Each single-strand steel strand 3 constituting the finished steel strand cable body I is cleaned and passed through the anchor cup 8, and each single-strand single-strand steel strand 3 is respectively penetrated into the tapered anchor hole 601 of the 6 anchor plate, A tapered sleeve 5 is placed on the center wire 301 of each single-strand steel strand 3, and the center wire is subjected to heading processing to form a heading 3011, and the remaining 6 side wires are located on the outside of the tapered sleeve 5 and are scattered in a conical shape. Distribute and form a single-strand steel strand anchor unit with the tapered anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com