Large-tonnage prestressed superposed crane beam and construction method

A crane beam and prestressing technology, which is applied in the field of reinforced concrete crane beams, can solve problems such as complex construction technology, complex formwork structure, and poor anti-corrosion performance, and achieve the effects of convenient manufacturing, reduced transportation costs, and high bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

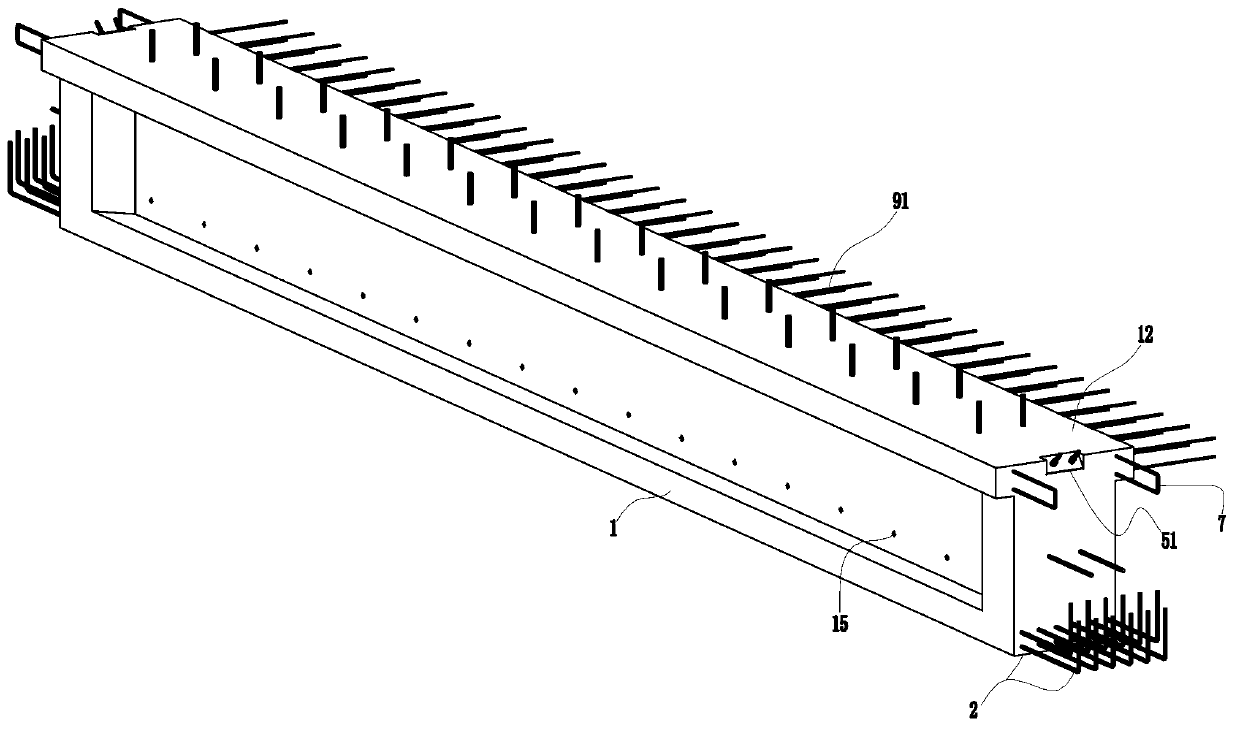

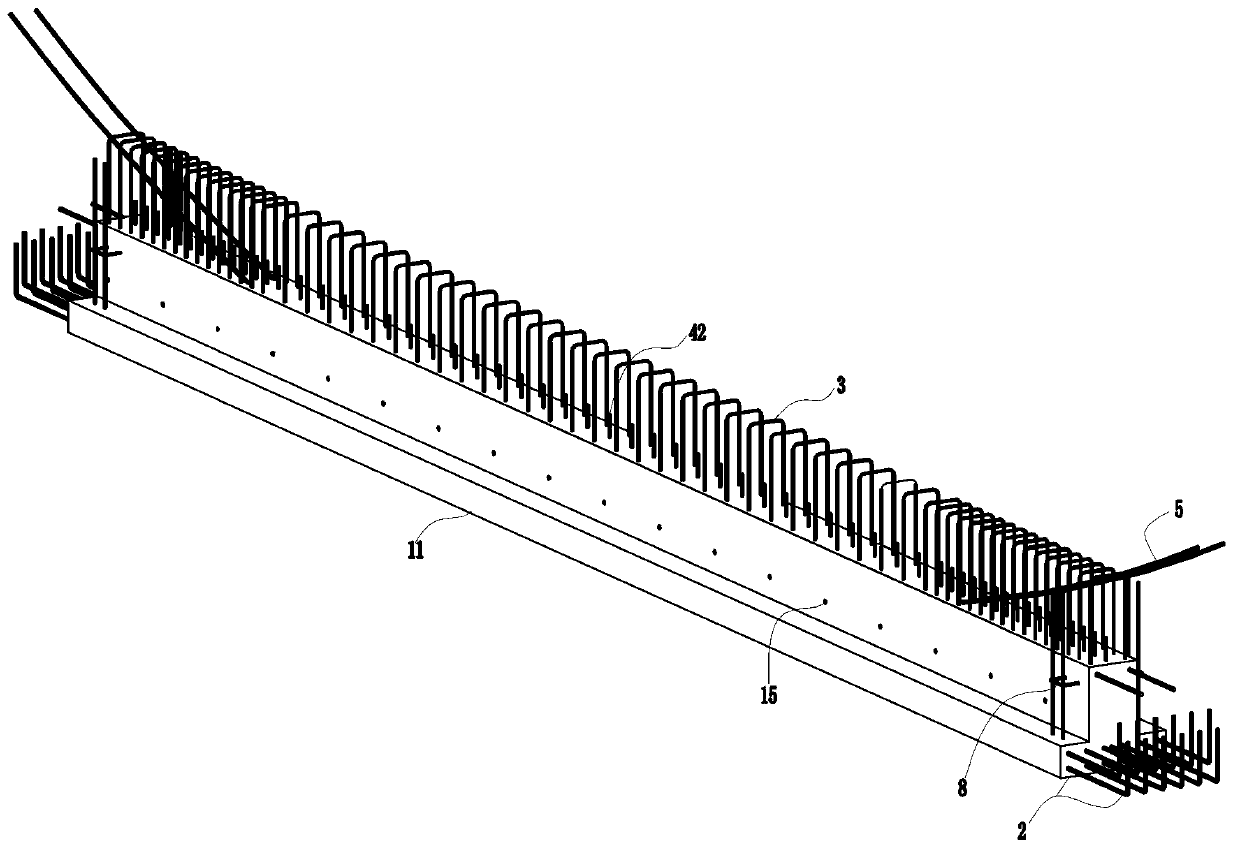

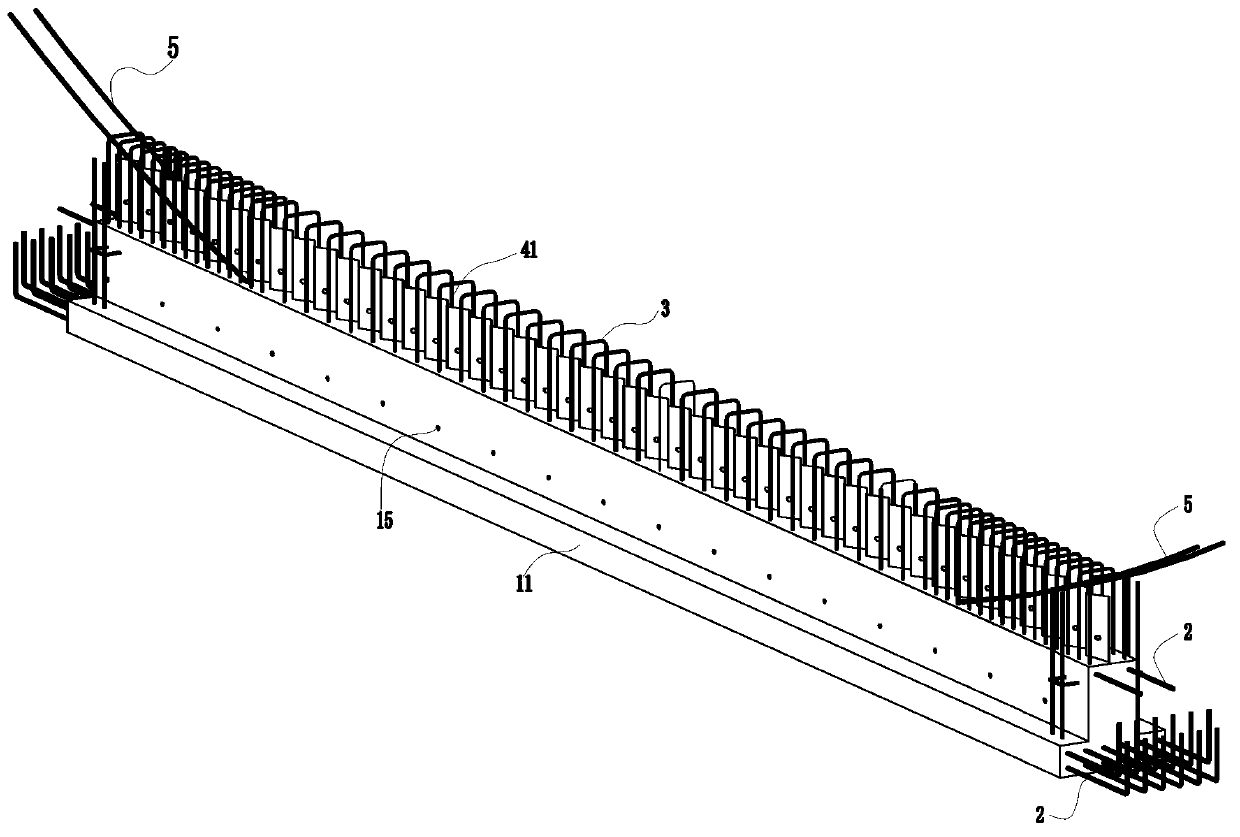

[0033] see figure 1 , Figure 5 to Figure 8 , in the embodiment of a large-tonnage prestressed composite crane girder 1 given in the present invention, it includes an inverted T-shaped prefabricated beam part 11 and a T-shaped post-cast concrete part 12, and the two parts are combined to form an I-shaped crane girder 1. The inverted T-shaped prefabricated beam 11 includes a web and a lower flange with equal cross-sections along the longitudinal direction, and pre-tensioned prestressed steel strands 2 are embedded longitudinally in the beam body. Stirrups 3 are embedded in the web of the beam body. The stirrups 3 are exposed to a certain length on the upper surface of the web and embedded in the post-cast concrete part 12. The joint surface of the prefabricated and cast-in-place part is connected with a shear member 41 or 42. Composite beams are used to facilitate batch prefabrication of inverted T-shaped prestressed components in the factory, and pretensioned prestressing tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com