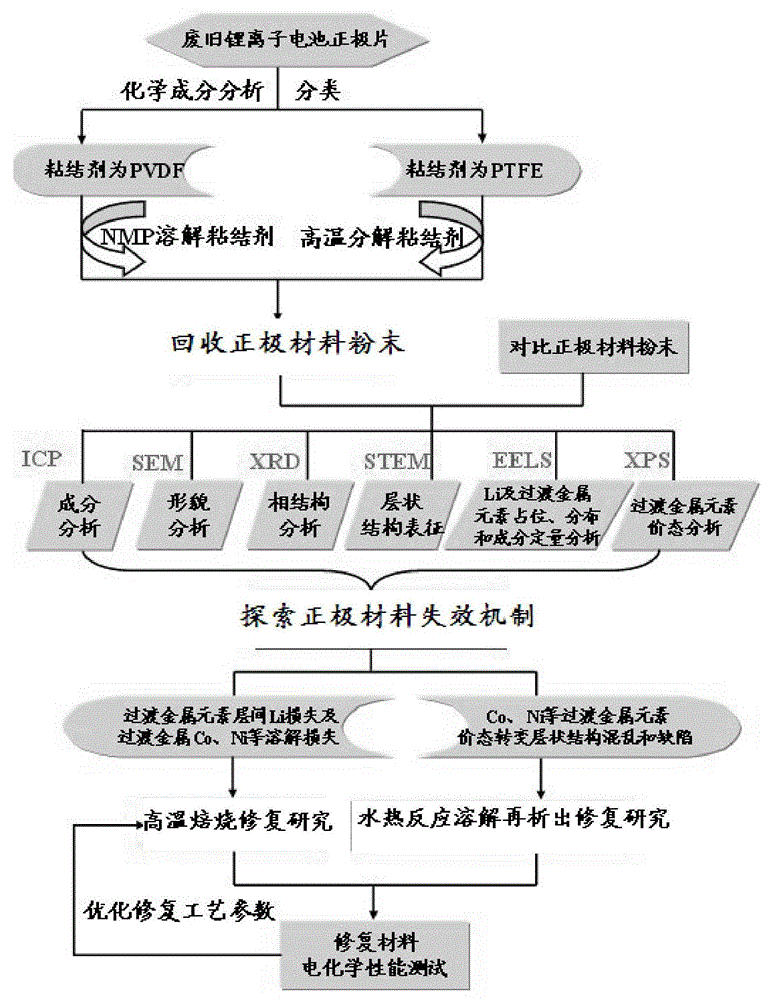

Method for direct recovery and restoration of lithium ion battery positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in the field of resource recycling and can solve the problems of waste liquid generation, high cost, secondary pollution, etc. in the separation process of electrode sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

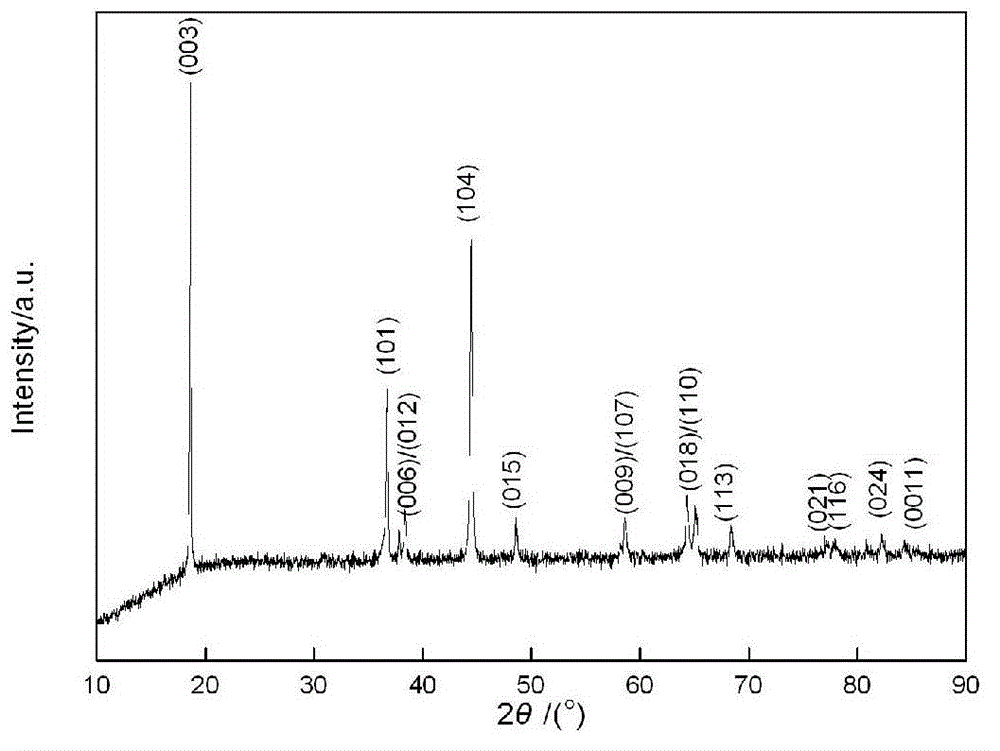

[0060] The cathode material is Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 After dismantling the lithium-ion battery, select 100g of the positive electrode sheet whose binder is PVDF, and soak it in NMP at 60°C. After the active material powder is separated from the aluminum foil current collector, filter, wash, and vacuum-dry to obtain the recovered powder, organic solvent NMP can be recycled after treatment. Add the above powder into water, pour it into a separatory funnel and let it stand for 30 minutes. The acetylene black conductive agent floats above the water, and the positive electrode material sinks to the bottom. The powder at the bottom flows out, and is filtered and dried to obtain the positive electrode material powder. The XRD pattern is shown in figure 2 . ICP composition analysis shows that the chemical composition of the cathode material contains 7.01% lithium, 20.90% nickel, 20.80% cobalt and 19.86% manganese.

Embodiment 2

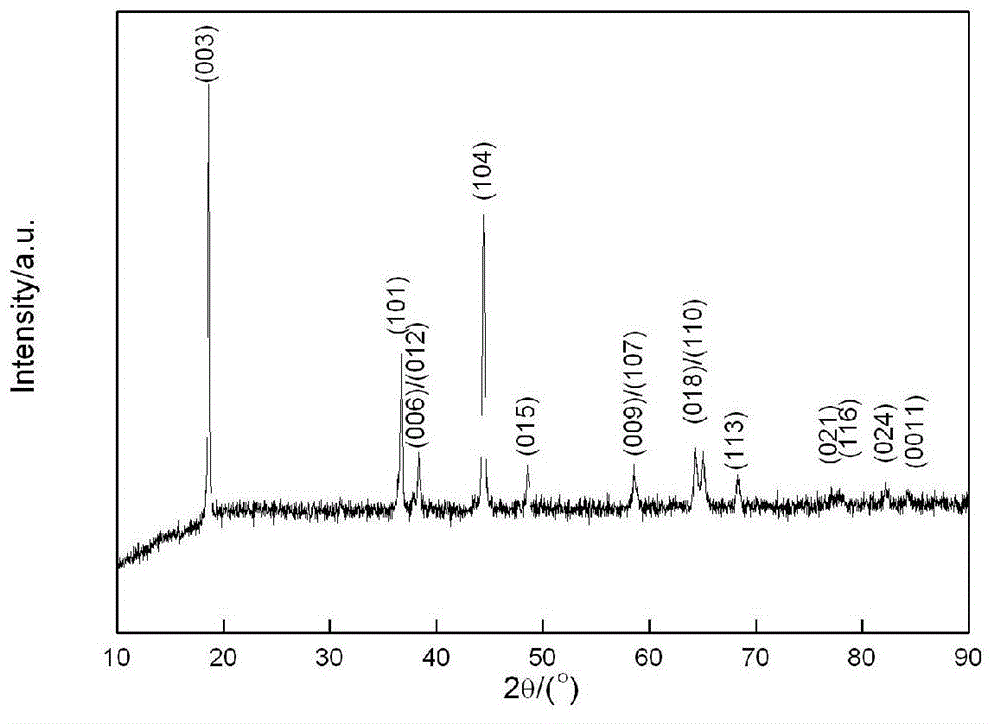

[0062] The cathode material is Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 After the lithium-ion battery is disassembled, 100g of the positive electrode sheet whose binder is PTFE is selected, and the N 2 Treat in a protected tube atmosphere furnace for 3 hours, and the tail gas needs to be collected and processed. After the furnace is cooled, take out the positive electrode sheet, mechanically rub the active material and the current collector to separate, use a 400-mesh standard sieve to sieve, take the undersieve, separate by heavy liquid method, and obtain the XRD pattern of the positive electrode material powder, see image 3 . ICP composition analysis shows that the chemical composition of the cathode material contains 6.47% lithium, 18.51% nickel, 18.73% cobalt, and 19.30% manganese.

Embodiment 3

[0064] figure 2 The positive electrode material powder XRD pattern that shown embodiment 1 reclaims can be seen and α-NaFeO 2 The standard diffraction peaks correspond, indicating that the recovered cathode material powder still has the typical α-NaFeO 2 structure Space group and hexagonal crystal system. Obvious (006) / (012) and (018) / (110) split peaks can be observed in the XRD pattern, indicating that the recovered cathode material powder still has a good layered structure. Comparing its chemical composition with Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 According to the theoretical composition, it is found that the lithium content has a small amount of loss, according to the chemical ratio, weigh Li 2 CO 3 Mix and ball mill with recycled powder, the molar ratio of Li / (Ni+Co+Mn) is 1.1:1, and then put it in a muffle furnace at 850°C for 10h to repair the recycled material. ICP composition analysis shows that the chemical composition of the repaired cathode material powder is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com